Preparation method of modified polyether-ether-ketone resin-based sizing agent for carbon fiber

A technology of polyether ether ketone resin and polyether ether ketone, which is applied in the field of preparation of modified polyether ether ketone resin-based sizing agents for carbon fibers, can solve the problems of poor high temperature resistance, difficulty in improving the interface bonding between carbon fiber and resin matrix, and resin Problems such as poor matrix compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

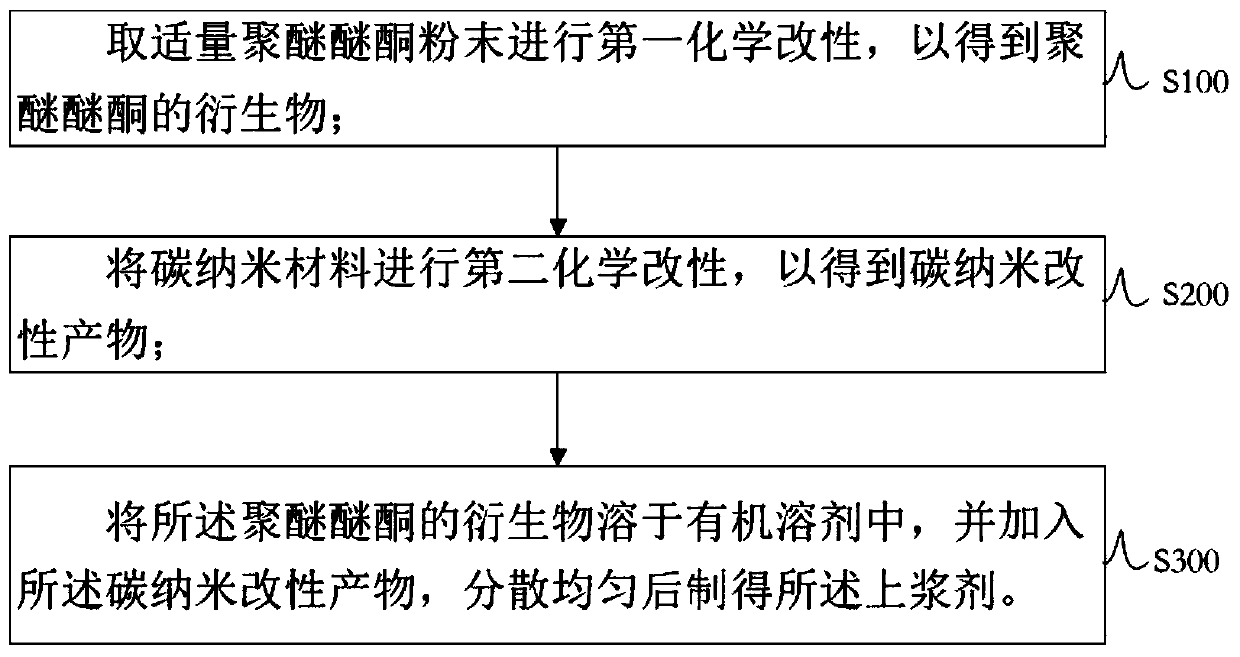

[0024] See figure 1 , figure 1 It is a flow chart of a preparation method of a modified polyetheretherketone resin-based sizing agent for carbon fibers provided by an embodiment of the present invention. An embodiment of the present invention provides a method for preparing a modified polyetheretherketone resin-based sizing agent for carbon fibers. The method for preparing a modified polyetheretherketone resin-based sizing agent for carbon fibers includes:

[0025] Step S100, take an appropriate amount of polyetheretherketone powder and perform the first chemical modification to obtain derivatives of polyetheretherketone. Wherein, the first chemical modification is sulfonation modification or hydroxylation modification. When the first chemical modification is sulfonation modification, the polyether ether ketone powder is obtained through the sulfonation modification to obtain PEEK- SO 3 Na, PEEK is polyether ether ketone, PEEK-SO 3 Na is a sulfonated derivative of polyethe...

Embodiment 1

[0030] (1) Add concentrated sulfuric acid with a volume of 100ml and dried PEEK powder with a mass of 2g into a three-necked flask, and perform mechanical stirring.

[0031] (2) Raise the temperature to 50° C. and react for 3 hours; then let stand to cool.

[0032] (3) Add the reacted solution drop by drop into sodium hydroxide (NaOH) solution, filter and dry to obtain the sulfonated derivative of PEEK, denoted as PEEK-SO 3 Na.

[0033] (4) Take 1g of carbon nanotube (CNT) and put it into a conical flask with a volume of 100ml, add concentrated nitric acid with a volume of 15ml and concentrated sulfuric acid with a volume of 45ml in turn, and shake well at the same time.

[0034] (5) Put the Erlenmeyer bottle into the ultrasonic instrument for 6 hours of ultrasonication. During the ultrasonication process, use an ice pack to prevent the temperature from being too high, and cool to room temperature after the end.

[0035] (6) Centrifugal separation, recovery of excess mixed a...

Embodiment 2

[0039] (1) Add concentrated sulfuric acid with a volume of 100ml and dried PEEK powder with a mass of 2g into a three-necked flask, and perform mechanical stirring.

[0040] (2) Raise the temperature to 50° C. and react for 3 hours; then let stand to cool.

[0041] (3) Add the reacted solution drop by drop into the NaOH solution, filter and dry to obtain the sulfonated derivative of PEEK, denoted as PEEK-SO 3 Na.

[0042] (4) Measure concentrated sulfuric acid with a volume of 46ml in a three-necked flask, place it in an ice bath to below 0°C, add graphite with a mass of 2g and sodium nitrate with a mass of 1g in sequence, and after stirring for one hour, slowly add 6g of high-quality sulfuric acid Potassium manganate, control the temperature not to exceed 20°C.

[0043] (5) Place the reaction in an oil bath, stir and react at 40°C for 0.5 hours, then add deionized water with a volume of 92ml, raise the temperature to 92°C and stir for 0.5 hours, finally add deionized water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com