A preparation method of multifunctional electrospun fiber dressing

An electrospinning, multi-functional technology, applied in fiber processing, filament/thread forming, textiles and papermaking, etc., can solve the problems of less research and achieve uniform diameter, soft texture, good filling and adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a kind of preparation method of multifunctional electrostatic spinning fiber dressing, and this method comprises:

[0031] Step 1: grafting functional groups to the polymer material; the functional groups are antioxidant groups or / and antibacterial groups; the polymer material has the function of stimulating macrophage transformation;

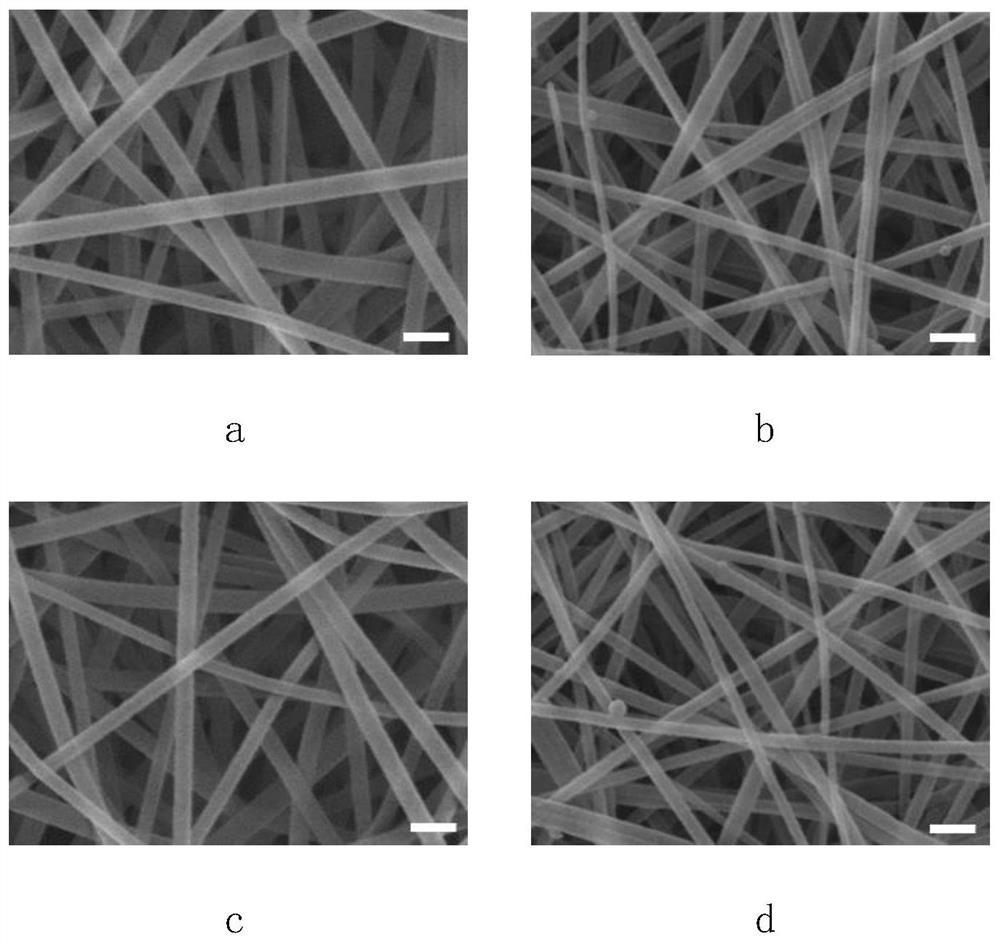

[0032] Step 2: Dissolving the polymer material grafted with functional groups obtained in Step 1 in a solvent for electrospinning to obtain an electrospun fiber mat;

[0033] Step 3: Place the electrospun fiber mat obtained in Step 2 in a crosslinking agent solution, soak it, take out the fiber mat, wash it, blow dry or dry it, and obtain a multifunctional electrospun fiber dressing.

[0034] According to the present invention, first prepare the macromolecular material grafted with functional groups, the preparation method of the macromolecular material grafted with functional groups is to blend the sm...

Embodiment 1

[0047] Dissolve 200mg of hyaluronic acid (HA) in 100ml of deionized water, stir magnetically until completely dissolved, add 64mg of 2-(methylthio)ethylamine, 53mg of 1-hydroxybenzotriazole and 75mg of EDC, and stir in an ice bath for 30min. Add 1M NaOH or 1M HCl to adjust the pH value to 6.5-7.0, continue ice bathing for 30 min, and then react at room temperature for 3 days. The resulting reaction solution was settled with ice ethanol and filtered to keep the precipitate. The precipitate was re-dissolved with deionized water, filtered, and the filtrate was retained for dialysis with deionized water for 3 days. Finally, the dialysate was freeze-dried to obtain hyaluronic acid (HA-S) grafted with thioether groups.

[0048] Dissolve 120mg of HA-S in 7.2ml of ammonia water and 2.8ml of N-methylpyrrolidone, stir at room temperature until completely dissolved, and use the resulting solution for spinning.

[0049] The resulting spinning solution is spun, and the electrospinning op...

Embodiment 2

[0058] Dissolve 200mg of sodium alginate (SA) in 80ml of deionized water, magnetically stir until completely dissolved, add 96mg of aminoethyl sulfide, 153mg of 1-hydroxybenzotriazole and 120mg of EDC, stir in an ice bath for 30min, add 1M NaOH or Adjust the pH value to 6.5-7.0 with 1M HCl, and continue the ice bath for 30 minutes. Then react at room temperature for 4h. The resulting reaction solution was settled with ice ethanol and filtered to keep the precipitate. The precipitate was re-dissolved with deionized water, filtered, and the filtrate was retained for dialysis with deionized water for 3 days. Finally, the dialysate was freeze-dried to obtain alginic acid grafted with antioxidant thioether groups (SA-S).

[0059] Dissolve 100mg of SA-S in 40ml of water, add 5ml of 1M NaOH and 50mg of glycidyltrimethylamine chloride (GTAC), and stir in a water bath at 60°C for 5h. 1% glacial acetic acid neutralized the pH, the reaction solution was dialyzed with deionized water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com