Zinc stearate dispersion solution and preparation method thereof

A technology of zinc stearate and dispersion liquid, applied in textile and papermaking, fiber raw material treatment, paper coating and other directions, can solve the problems of incomplete product reaction, unsatisfactory product quality and high process requirements, and achieve ideal lubrication effect and product quality. The effect of ideal quality and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

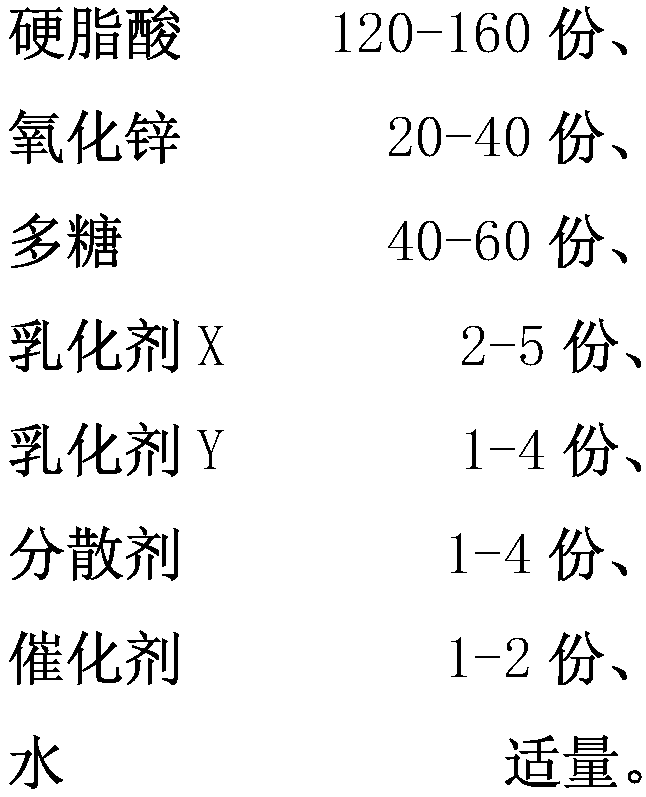

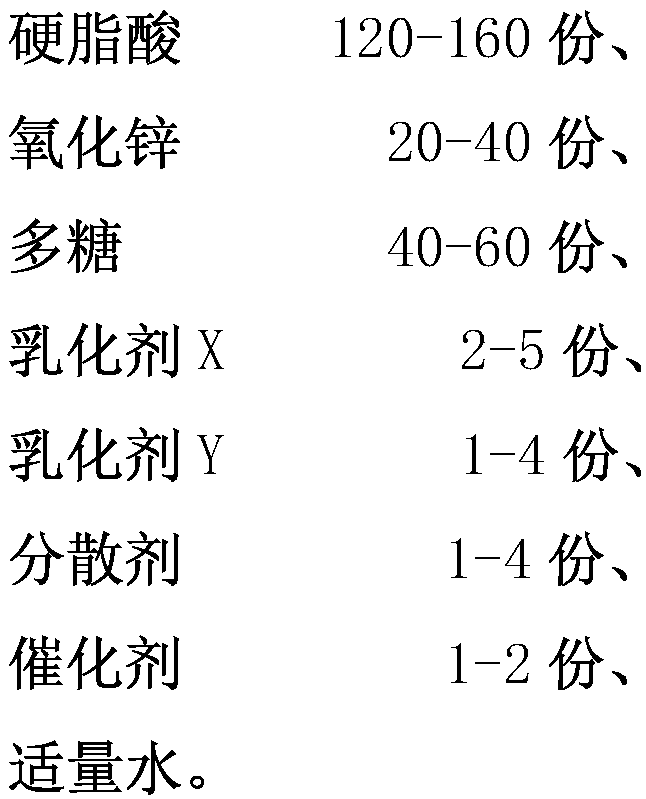

Method used

Image

Examples

Embodiment 1

[0037] According to the formula ratio of zinc stearate emulsion, take 100 parts of water, 90 parts of stearic acid, 30 parts of maltodextrin, 3 parts of fatty acid methyl ester polyoxyethylene ether (10EO) sodium sulfonate, sorbitan monostearate Put 2 parts of acid ester, 1 part of sodium hexametaphosphate, and 2 parts of polyvinyl alcohol in a container, emulsify and stir at 85-90 ° C for 1 hour, add 0.5 parts of modified polysiloxane to defoam, and then add 50 parts of water , 20 parts of zinc oxide, 1.0 part of hydrogen peroxide, and 1 part of sodium polyacrylate are uniformly dispersed, stirred at constant temperature for 2.5 hours, rapidly cooled to below 60 degrees, passed through a homogenizer, and discharged, adding 15 parts of polyethylene glycol 200 , adjust the solid content to 50%-60%, and stir evenly to obtain the target product.

Embodiment 2

[0039] According to the formula ratio of zinc stearate emulsion, take 100 parts of water, 80 parts of stearic acid, 40 parts of oxidized starch, 3 parts of fatty acid methyl ester polyoxyethylene ether (10EO) sodium sulfonate, sorbitan monostearic acid Put 2 parts of ester, 2 parts of sodium tripolyphosphate, and 1 part of carboxymethyl cellulose in a container, emulsify and stir at 85-90°C for 1 hour, add 0.5 parts of modified polysiloxane to defoam, and then add 50 parts of Water, 25 parts of zinc oxide, 2 parts of ammonia water and 1.5 parts of polyvinyl alcohol are uniformly dispersed, stirred at constant temperature for 2.5 hours, rapidly cooled to below 60 degrees, passed through a homogenizer, and discharged, adding 20 parts of glycerol, Adjust the solid content to 50%-60%, and stir evenly to obtain the target product.

Embodiment 3

[0041] According to the formula ratio of zinc stearate emulsion, take 105 parts of water, 100 parts of stearic acid, 20 parts of maltose, 3 parts of fatty acid methyl ester polyoxyethylene ether (10EO) sodium sulfonate, sorbitan monostearate 1 part, 2 parts of sodium hexametaphosphate, and 3 parts of polyvinyl alcohol are placed in a container, emulsified and stirred for 1 hour at 85-90 ° C, and 0.5 parts of modified polysiloxane are added to defoam, and then 50 parts of water, 20 Part of zinc oxide, 1.5 parts of hydrogen peroxide and 2.0 parts of sodium polyacrylate are uniformly dispersed, stirred at constant temperature for 2.5 hours, rapidly cooled to below 60 degrees, passed through a homogenizer, discharged, added 20 parts of urea, and adjusted to a solid content of 50 %-60%, stir evenly to get the target product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com