A light-weight slow-release denitrification and dephosphorization material and its preparation method and application

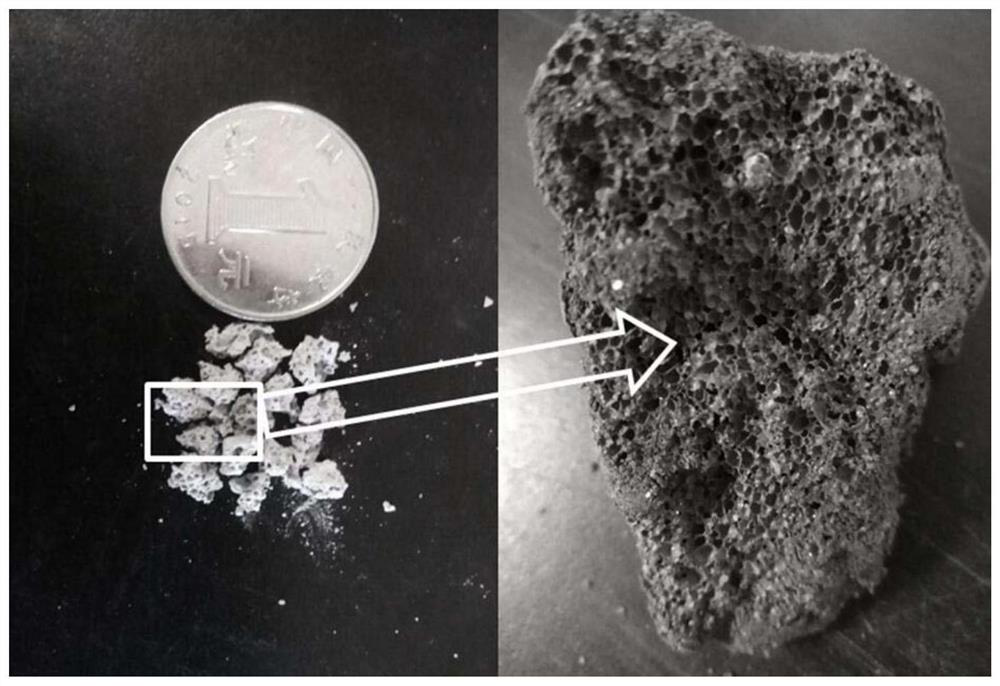

A denitrification and phosphorus removal, lightweight technology, used in applications, other household appliances, chemical instruments and methods, etc., can solve the problem of high density and heavy pyrite packing, which cannot be used in fluidized bed reactors and biological filters. Filler blockage and other problems, to achieve the effect of controllable density, easy microbial film hanging, and not easy to block

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In this embodiment, 800 g of pyrrhotite with a sulfur grade of 45%-50% from Anhui Province and a particle size of less than 0.3 mm was selected.

[0036] Mix 20% cement, 75% pyrrhotite, 4.99% foaming agent sodium percarbonate, and 0.01% foam stabilizer calcium stearate in mass percentage, and continue stirring during the mixing process, and the stirring speed is 30r / min, the stirring time is 60s to obtain a uniform dry powder mortar; add water to the dry powder mortar, the quality of the added water is 30% of the dry powder mortar quality, pour the above mortar with water into the cement mortar mixer Stirring is carried out, the stirring speed is 180r / min, and the stirring time is 200s. After the stirring reaction, a light-weight slow-release denitrification and phosphorus removal material is prepared. The obtained lightweight slow-release denitrification and phosphorus removal material is made into a standard test block of 15cm*15cm*15cm, and it is ready to use after 10...

Embodiment 2

[0039] The basic content of this embodiment is the same as that of Embodiment 1, except that: this embodiment selects 800 g of pyrite with a sulfur grade of 30%-34% from Guangdong, and the particle size is less than 0.3 mm.

[0040] Mix 65% cement, 30% pyrite, 0.1% foaming agent hydrogen peroxide, and 4.9% surfactant type foam stabilizer fatty acid ethanolamide in mass percentage, and continue stirring during the mixing process, and the stirring speed is 200r / min, the stirring time is 20s to obtain a uniform dry powder mortar; add water to the dry powder mortar, the quality of the added water is 70% of the dry powder mortar quality, pour the above mortar with water into the cement mortar mixer Stirring is carried out, the stirring speed is 250r / min, and the stirring time is 100s. After the stirring reaction, a light-weight slow-release denitrification and phosphorus removal material is prepared. The obtained lightweight slow-release denitrification and phosphorus removal mate...

Embodiment 3

[0043] The basic content of this embodiment is the same as that of Embodiment 1, except that: this embodiment selects 800 g of pyrite with a sulfur grade of 45%-48% from Hunan and a particle size of 0.3 mm.

[0044] Mix 50% cement, 40.5% pyrite, 5% foaming agent sodium dodecylbenzene sulfonate, and 4.5% foam stabilizer calcium stearate in mass percentage, and continuously stir during the mixing process. The speed is 60r / min, and the stirring time is 50s to obtain a uniform dry powder mortar; add water to the dry powder mortar, the quality of the added water is 50% of the quality of the dry powder mortar, pour the above mortar with water into Stirring is carried out in a cement mortar mixer, the stirring speed is 300r / min, and the stirring time is 60s. After the stirring reaction, a light slow-release denitrification and phosphorus removal material is prepared. The obtained lightweight slow-release denitrification and phosphorus removal material is made into a standard test blo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com