Carbendazim Cleaner Production System

A clean production and carbendazim technology, applied in the field of carbendazim clean production system, can solve the problems of long process flow, cumbersome operation, easy blockage of equipment pipelines, etc., achieve simple equipment process flow, reduce calcium ion content, prolong The effect of the production run cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For ease of understanding, the technical solutions and technical effects of specific embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings of the present invention.

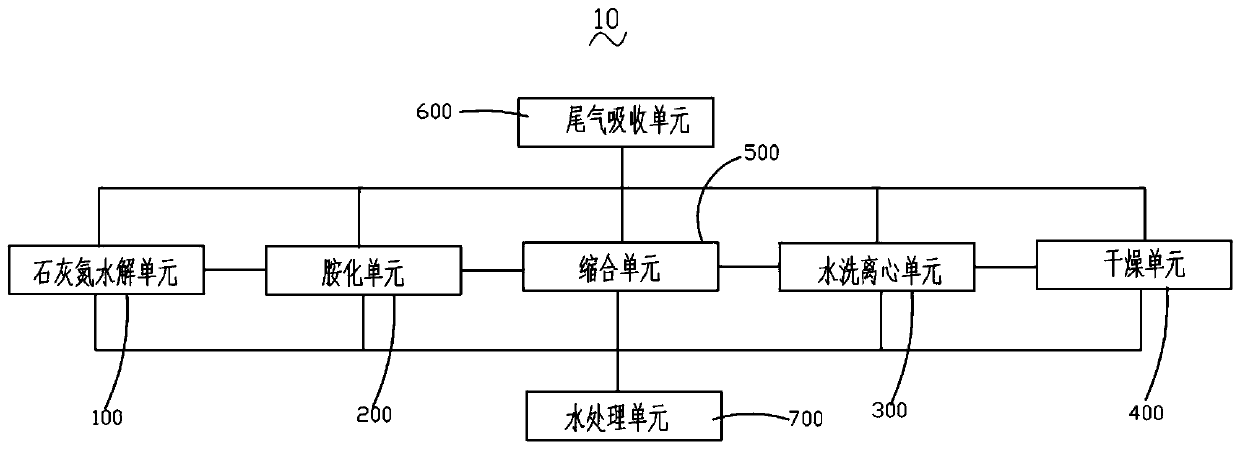

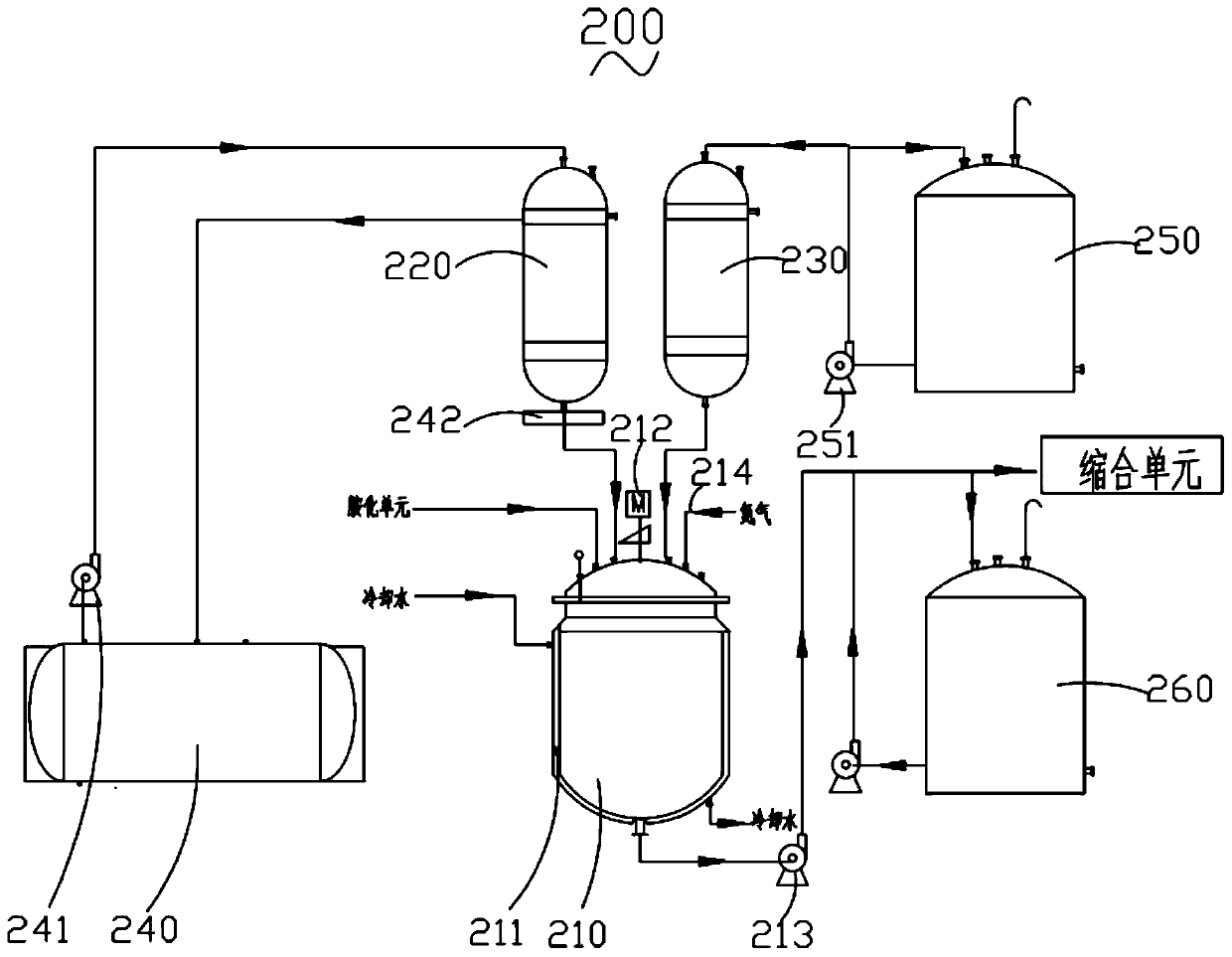

[0031] Please seefigure 1 , In a specific embodiment of the present invention, a carbendazim clean production system 10 includes a lime nitrogen hydrolysis unit 100 , an amination unit 200 , a condensation unit 300 , a water washing centrifugal unit 400 and a drying unit 500 .

[0032] The lime nitrogen hydrolysis unit 100 receives lime nitrogen and sodium carbonate as raw materials, independently hydrolyzes the lime nitrogen to generate cyanamide, and pumps the cyanamide to the amination unit 200 .

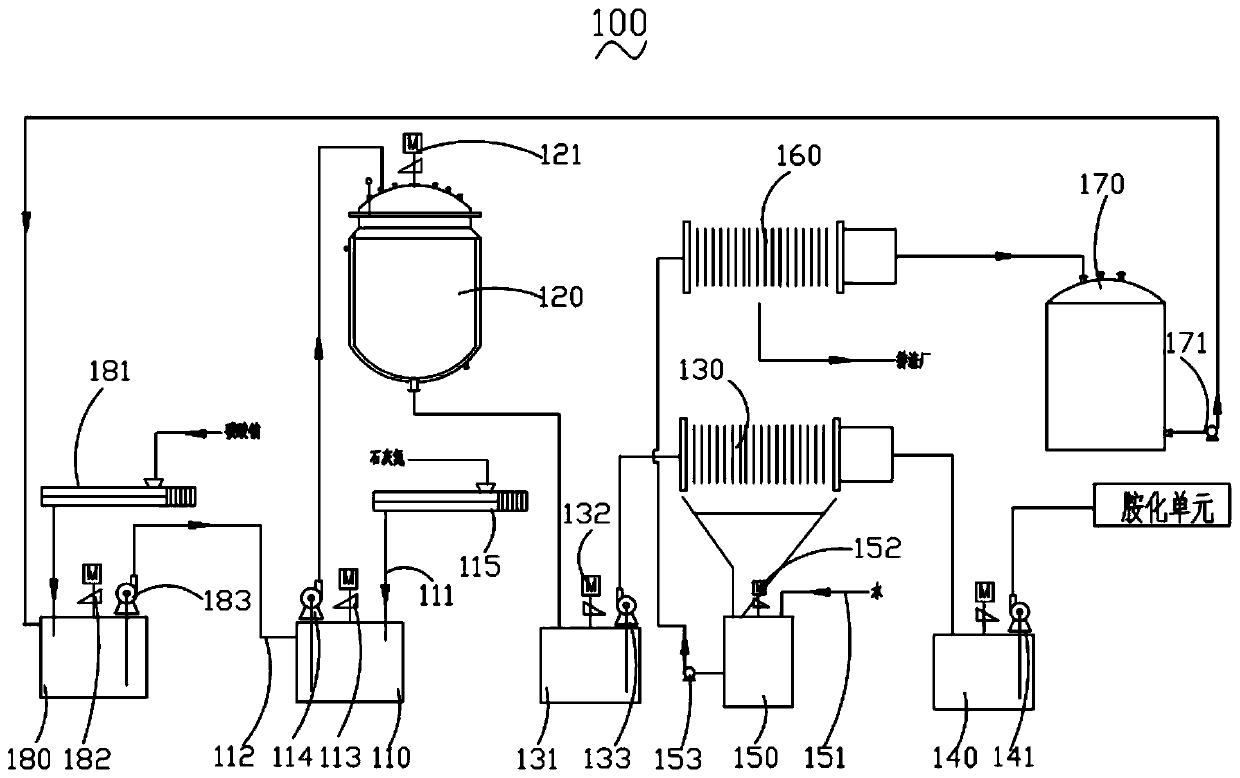

[0033] Please also refer to figure 2 , Specifically, the lime nitrogen hydrolysis unit 100 includes a ground mixing pool 110, a hydrolysis kettle 120, a decalcification filter press 130 and an intermediate cyanamide storage tank 140 conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com