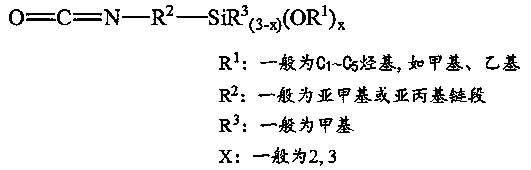

Method for preparing isocyanate-based silane by hydrosilylation reaction

A technology for hydrosilylation reaction and isocyanate, which is applied in chemical instruments and methods, compounds of Group 4/14 elements of the periodic table, organic chemistry, etc., can solve the problems of slow cracking speed, high energy consumption and low efficiency, etc. Achieve the effect of less impurities, low energy consumption and high reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

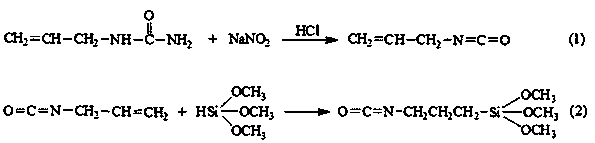

[0032] 300 g of allylurea, 1200 g of toluene and 30 g of tetrabutylammonium bromide were put into a 2000 ml four-necked reaction flask equipped with mechanical stirring, a thermometer and a constant pressure dropping funnel. And add 950g of sodium nitrite aqueous solution (42% concentration) and 500g of concentrated hydrochloric acid into the constant pressure dropping funnel, under the condition of ice-water bath, start the mechanical stirring, keep the system temperature at 0°C, after 30 minutes, at the mechanical stirring speed Under the condition of 100-300 revolutions per minute, start to add the aqueous solution of sodium nitrite and concentrated hydrochloric acid dropwise, and the dropping time is controlled at 5h. After the reaction is completed, 3-isocyanatopropylene is obtained through filtration, layering, distillation, etc. The product is 229.3g, the molar yield is 92%, and the content is 99.3%.

[0033]Put 249.3 g of 3-propene isocyanate into a 2000 ml four-necked...

Embodiment 2

[0035] 300 g of allylurea, 1200 g of toluene and 30 g of tetrabutylammonium bromide were put into a 2000 ml four-necked reaction flask equipped with mechanical stirring, a thermometer and a constant pressure dropping funnel. And add 950g of sodium nitrite aqueous solution (42% concentration) and 500g of concentrated hydrochloric acid into the constant pressure dropping funnel, under the condition of ice-water bath, start the mechanical stirring, keep the system temperature at 1°C, after 30 minutes, at the mechanical stirring speed Under the condition of 200 revolutions per minute, the aqueous solution of sodium nitrite and concentrated hydrochloric acid were added dropwise, and the dropping time was controlled at 6 hours. After the reaction was completed, the 3-isocyanate propene product 229.3 was obtained through filtration, layering, distillation, etc. g, the molar yield is 92%, and the content is 99.3%.

[0036] Put 249.3g of 3-propene isocyanate into a 2000ml four-necked r...

Embodiment 3

[0038] 300 g of allylurea, 1200 g of toluene and 30 g of tetrabutylammonium bromide were put into a 2000 ml four-necked reaction flask equipped with mechanical stirring, a thermometer and a constant pressure dropping funnel. And add 950g of sodium nitrite aqueous solution (42% concentration) and 500g of concentrated hydrochloric acid into the constant pressure dropping funnel, under the condition of ice-water bath, start the mechanical stirring, keep the system temperature at 2°C, after 30 minutes, at the mechanical stirring speed Under the condition of 250 revolutions per minute, the aqueous solution of sodium nitrite and concentrated hydrochloric acid were added dropwise, and the dropping time was controlled at 7h. After the reaction was completed, the 3-isocyanate propene product 229.3 was obtained through filtration, layering, distillation, etc. g, the molar yield is 92%, and the content is 99.3%.

[0039] In the 2000ml four-necked reaction flask with mechanical stirring, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com