Two-component rubber modified asphalt waterproof coating material, preparation method and applications

A kind of asphalt waterproof coating, rubber modification technology, applied in the direction of asphalt coating, chemical instruments and methods, roofs using flexible materials, etc., can solve problems such as loss of waterproof effect, coating quality damage, coating layering, etc., to ensure storage Stability, reduced high temperature viscosity, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

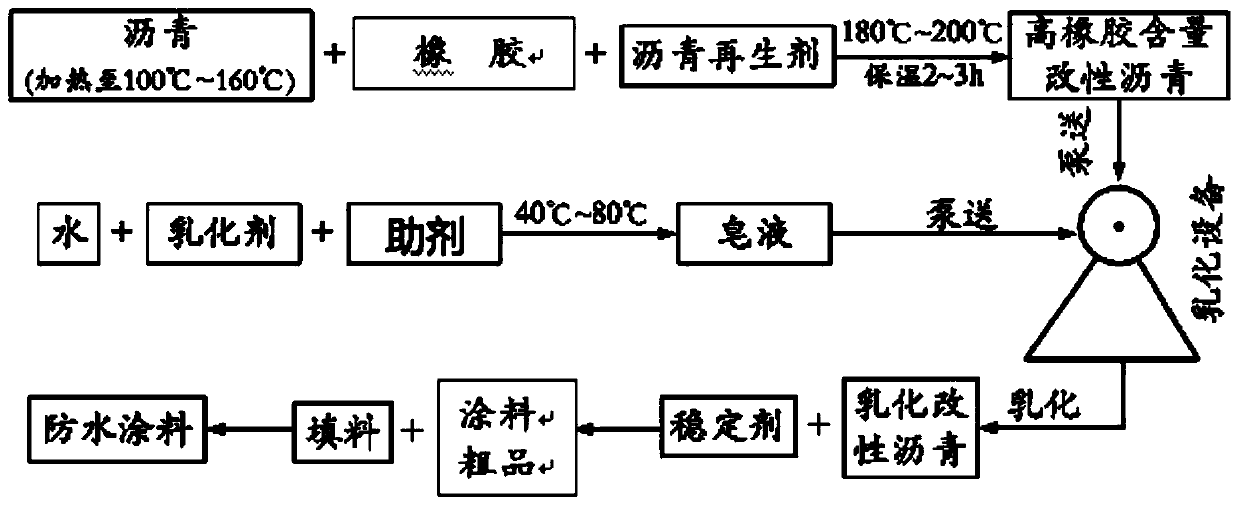

Method used

Image

Examples

preparation example Construction

[0067] In the preparation method of the above product, the rubber content in the modified asphalt prepared in the first step is 10%-22%.

[0068] In the above product and its preparation method, the other additives are one of hydroxyethyl cellulose, hydroxypropyl cellulose, carboxymethyl cellulose, alkali-swellable associative thickener, and associative polyurethane thickener or more, the addition ratio is 0% to 5.0%.

[0069] In the above-mentioned product and preparation method thereof, the stabilizing agent is CaCl 2 One or more in , acid, alkali, alcohol; Acid preferred nitric acid, sulfuric acid, hydrochloric acid; Alkali preferred ammoniacal liquor, sodium hydroxide, sodium carbonate; Alcohol preferred polyvinyl alcohol, ethylene glycol, propylene glycol.

[0070] Among them, the stabilizer uses CaCl 2 , one or two of acids; and polyvinyl alcohol, ethylene glycol, and propylene glycol are universal stabilizers.

[0071] The emulsified modified asphalt waterproof coati...

Embodiment 1

[0081] A rubber-modified asphalt waterproof coating, including A component and B component, A component is a waterproof essence, and B component is a filler;

[0082] The mass percent of each raw material in A component is:

[0083] 110# asphalt: 28.3%

[0084] Star SBS Rubber: 15.1%

[0085] Asphalt regenerant: 13.5%

[0086] Sodium dodecylbenzenesulfonate: 3.9%

[0087] Polyvinyl alcohol: 0.2%

[0088] Hydroxyethylcellulose: 4.6%

[0089] Water: balance.

[0090] Component B: the filler is calcium oxide, accounting for 31%.

[0091] The preparation method of above-mentioned product is specifically described as follows:

[0092] One: Preparation of high rubber content modified asphalt;

[0093] First heat 110# asphalt to 100°C-160°C, then add star-shaped SBS rubber and asphalt regenerant, heat up, and modify at a constant temperature within the range of 180°C-200°C for 2-3 hours to obtain high rubber content modified asphalt;

[0094] Two: Soap preparation;

[0095]...

Embodiment 2

[0129] An emulsified modified asphalt waterproof coating, including A component and B component, A component is a waterproof essence, and B component is a filler;

[0130] The mass percent of each raw material in A component is:

[0131] 90# asphalt: 56%

[0132] SBR: 6.2%

[0133] Asphalt regenerant: 6.5%

[0134] Didodecyl ammonium bromide: 1.0%

[0135] Dilute sulfuric acid: 4.5%

[0136] Water: balance.

[0137] Component B: calcium carbonate powder, accounting for 27%.

[0138] Its preparation method is identical with embodiment 1 product.

[0139] According to the method requirements of GB / T 16777-2008 "Experimental Methods of Building Waterproof Coatings", the products prepared above were tested. After the waterproof coating is dried, the low temperature temperature: -25°C (2h without cracks), water absorption (48h) : 5.9%, heat resistance: 110°C, bond strength: 0.80MPa, stress relaxation: 29% (and does not separate from the bonding surface), bridging crack capac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| brittleness temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com