Dense grade asphalt mixture prepared from modified steel slag and preparation method of asphalt mixture

A technology of asphalt mixture and modified asphalt, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of restricting the large-scale utilization of steel slag, long aging treatment period, low steel slag production efficiency, etc. , to protect the natural ecological environment, improve water stability, good low temperature crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

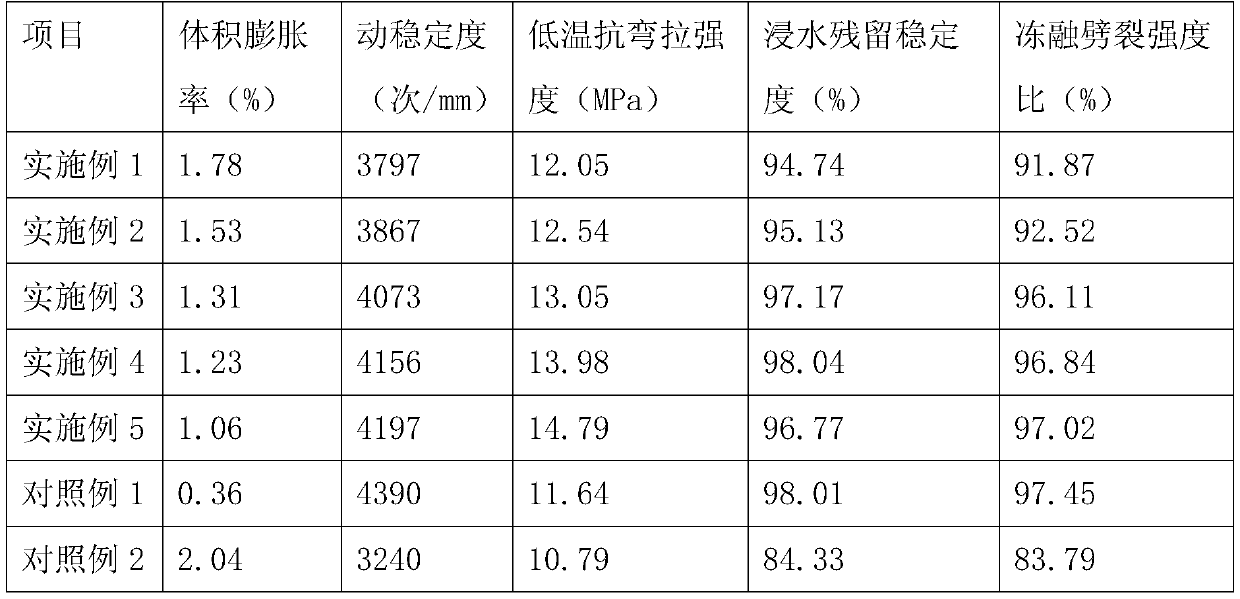

Examples

Embodiment 1

[0043] A dense asphalt mixture prepared by using modified steel slag, the dense asphalt mixture includes the following components in parts by mass: 4 parts of SBS modified asphalt, 25 parts of basalt aggregates with a particle size of 4.75 mm to 0.075 mm, 55 parts of water-based acrylic material modified steel slag with a particle size of 4.75 mm to 16 mm, and 4 parts of limestone slag with a particle size of no more than 0.075 mm;

[0044] The water-based acrylic material modified steel slag is common converter steel slag covered with water-based acrylic material on the surface, its immersion expansion rate is less than 1.5%, and the contact angle with water is greater than 90°; the water-based acrylic material includes the following components in parts by mass:

[0045] Acrylates: 165 parts of butyl acrylate, 210 parts of methyl methacrylate;

[0046] Organosiloxane containing terminal vinyl groups: 6 parts of vinyl triethoxysilane, 2 parts of vinyl cyclotetrasiloxane;

[0...

Embodiment 2

[0060] A dense asphalt mixture prepared by using modified steel slag, the dense asphalt mixture includes the following components in parts by mass: 4.2 parts of SBS modified asphalt, 30 parts of basalt aggregates with a particle size of 4.75 mm to 0.075 mm, 60 parts of water-based acrylic material modified steel slag with a particle size of 4.75 mm to 16 mm, and 5 parts of limestone slag with a particle size of no more than 0.075 mm;

[0061] The water-based acrylic material modified steel slag is common converter steel slag covered with water-based acrylic material on the surface, its immersion expansion rate is less than 1.5%, and the contact angle with water is greater than 90°; the water-based acrylic material includes the following components in parts by mass:

[0062] Acrylates: 170 parts of butyl acrylate, 215 parts of methyl methacrylate;

[0063] Organosiloxanes containing terminal vinyl groups: 7 parts of vinyl triethoxysilane, 2 parts of vinyl cyclotetrasiloxane;

...

Embodiment 3

[0077] A dense asphalt mixture prepared by using modified steel slag, the dense asphalt mixture includes the following components in parts by mass: 4.5 parts of SBS modified asphalt, 40 parts of basalt aggregates with a particle size of 4.75 mm to 0.075 mm, 60 parts of water-based acrylic material modified steel slag with a particle size of 4.75 mm to 16 mm, and 6 parts of limestone slag with a particle size of no more than 0.075 mm;

[0078] The water-based acrylic material modified steel slag is common converter steel slag covered with water-based acrylic material on the surface, its immersion expansion rate is less than 1.5%, and the contact angle with water is greater than 90°; the water-based acrylic material includes the following components in parts by mass:

[0079] Acrylates: 175 parts of butyl acrylate, 220 parts of methyl methacrylate;

[0080] Organosiloxanes containing terminal vinyl groups: 7 parts of vinyl triethoxysilane, 2 parts of vinyl cyclotetrasiloxane;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com