Polyelectrolyte composition hydrogel hemostatic based on polysaccharide/polypeptide

A polyelectrolyte and composite technology, which is applied in drug delivery, medical science, pharmaceutical formulation, etc., can solve the problems of inability to make gel microspheres and limited application fields, and achieve good biocompatibility and biocompatibility Good, the effect of improving the mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Use a mechanical stirrer to prepare a mixed polysaccharide solution, add 10g xanthan gum and 10g sodium alginate to 500mL aqueous solution to obtain a viscous mixed polysaccharide solution with a xanthan gum content of 2% and a sodium alginate content of 2%. This solution is marked as 1 number solution. Prepare the peptide solution using magnetic stirring, add 5g polylysine hydrochloride and 0.5g calcium chloride to 100mL water to obtain a mixed solution with 5% polylysine content and 0.5% calcium chloride content, which is marked as solution a. Add 5g polylysine hydrochloride and 1g calcium chloride to 100mL water to obtain a mixed solution with 5% polylysine content and 1% calcium chloride content, which is marked as solution b. Add 10g polylysine hydrochloride and 1g calcium chloride to 100mL water to obtain a mixed solution with a polylysine content of 10% and a calcium chloride content of 1%, which is marked as solution c. Take 1mL of No. 1 solution, take 3 times ...

Embodiment 2

[0045] Use mechanical stirrer to prepare mixed polysaccharide solution, add 10g xanthan gum, 10g sodium alginate and 10g hyaluronic acid to 500mL aqueous solution, obtain xanthan gum content 2%, sodium alginate content 2%, hyaluronic acid content 2% Viscous mixed polysaccharide solution, the solution is marked as No. 2 solution. Take 1mL of No. 2 solution, take 3 times in total, put it in three petri dishes, and mix it with 1mL of solution a / b / c in Example 1 respectively, and the mixed solution forms a hydrogel within 50s / 30s / 20s glue.

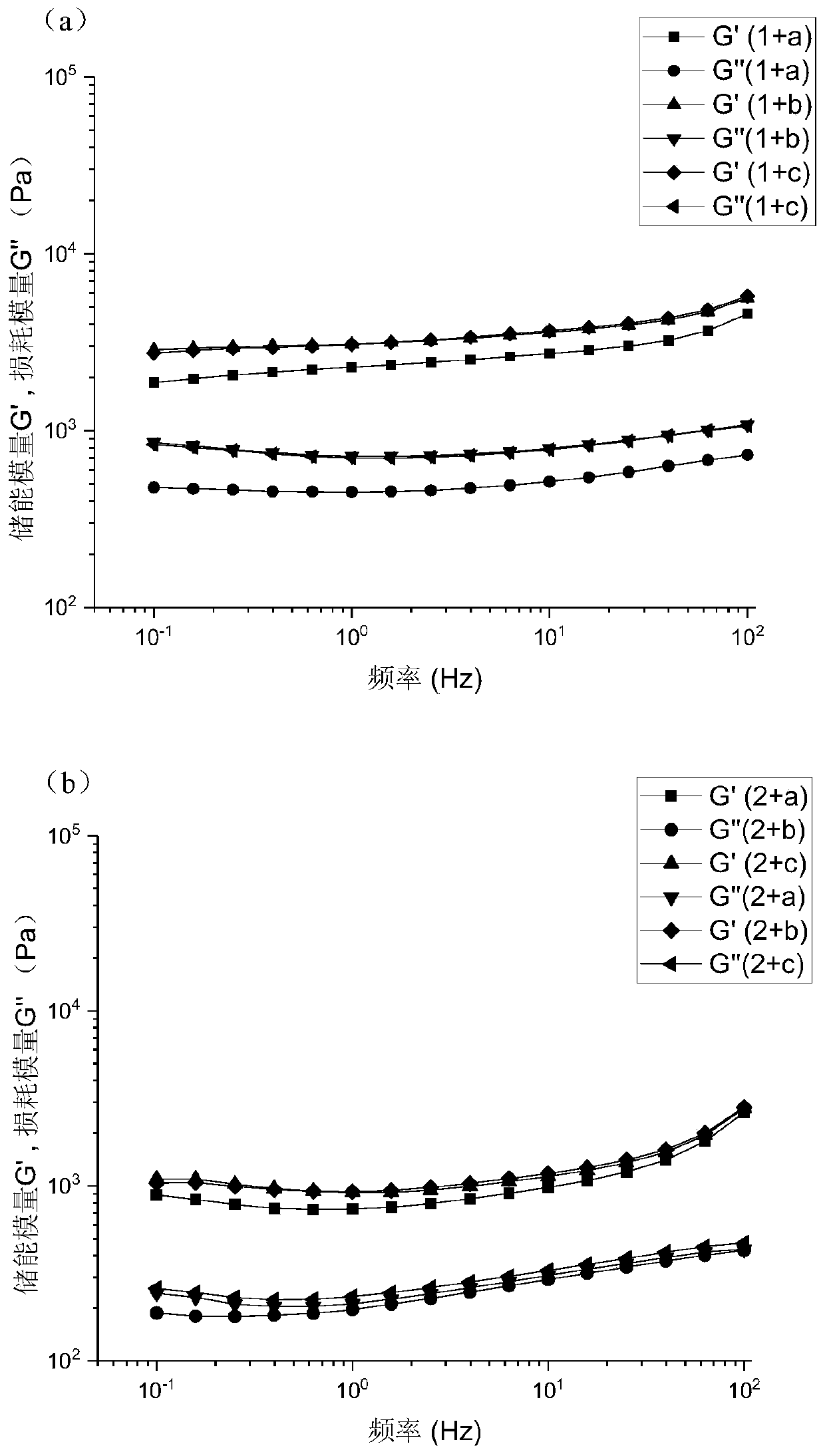

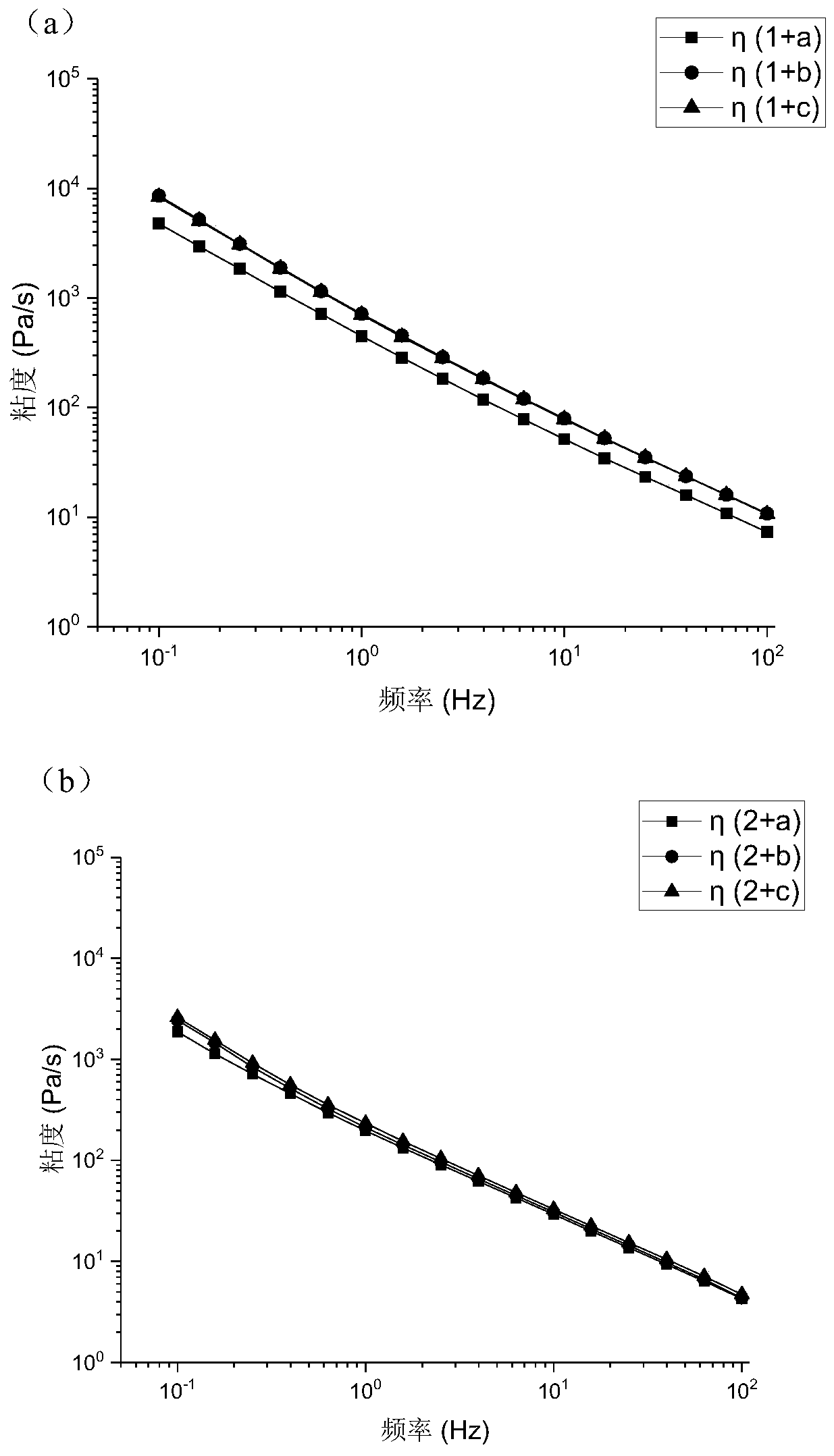

[0046] figure 1 middle, figure 1 (a) is the storage modulus and the loss modulus value of the polyelectrolyte composite hydrogel prepared in embodiment 1, figure 1 (b) is the storage modulus and the loss modulus value of the polyelectrolyte composite hydrogel prepared in Example 2 Wherein G is the storage modulus, unit Pa; G' is the loss modulus, unit Pa, test condition The temperature is 25°C, the oscillation pressure is 1Pa, and the osci...

Embodiment 3

[0049] Use mechanical stirrer to prepare mixed polysaccharide solution, add 5g xanthan gum, 15g sodium alginate and 5g chondroitin sulfate in 500mL aqueous solution, obtain xanthan gum content 1%, sodium alginate content 3%, chondroitin sulfate content 1% Viscous mixed polysaccharide solution, the solution is marked as No. 3 solution. Take 1mL of No. 3 solution, take it 3 times in total, place it in three petri dishes, and mix it with 1mL of the solution a / b / c in Example 1 respectively, and the mixed solution forms hydrocoagulation within 50s / 40s / 30s respectively. glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com