Submerged fermentation method of Bacillus licheniformis and its application

A technology of submerged fermentation of Bacillus licheniformis, applied in the submerged fermentation of Bacillus licheniformis, the application field of wettable powder prepared by Bacillus licheniformis, can solve the problem of low spore content and sporulation rate, deterioration of fermentation broth, low yield of spores, etc. problems, to achieve the effect of increasing the amount of spore formation, prolonging the stable period, and increasing the rate of spores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of Bacillus licheniformis wettable powder:

[0038] (1) Strain activation: Streak inoculation of Bacillus licheniformis on a nutrient agar medium plate for culture, culture at 36°C for 24 hours, then pick a single colony and transfer it to a nutrient agar slant, culture at 36°C for 24 hours Get activated bacteria.

[0039] (2) Preparation of primary seed liquid in shake flasks: 500 mL of seed culture medium containing 5 g of yeast extract, 1 g of peptone, 1 g of glucose, and pH 7.0 ± 0.1 were loaded into two 2000 mL Erlenmeyer flasks respectively. The activated strains were inoculated into the shake flask seed medium with an inoculation loop, and the culture conditions were as follows: temperature 36°C, shaker speed 160r / min, culture time 12h.

[0040] (3) Preparation of the secondary seed solution in the seed tank: the seed solution obtained in step (2) is microscopically checked for no bacteria contamination, and then inserted into a 2% inoculum containin...

Embodiment 2

[0048] Preparation of Bacillus licheniformis wettable powder:

[0049] (1) Strain activation is the same as in Example 1.

[0050] (2) The preparation of the primary seed solution of the shake flask is the same as in Example 1.

[0051] (3) The preparation of the secondary seed liquid in the seed tank is the same as in Example 1.

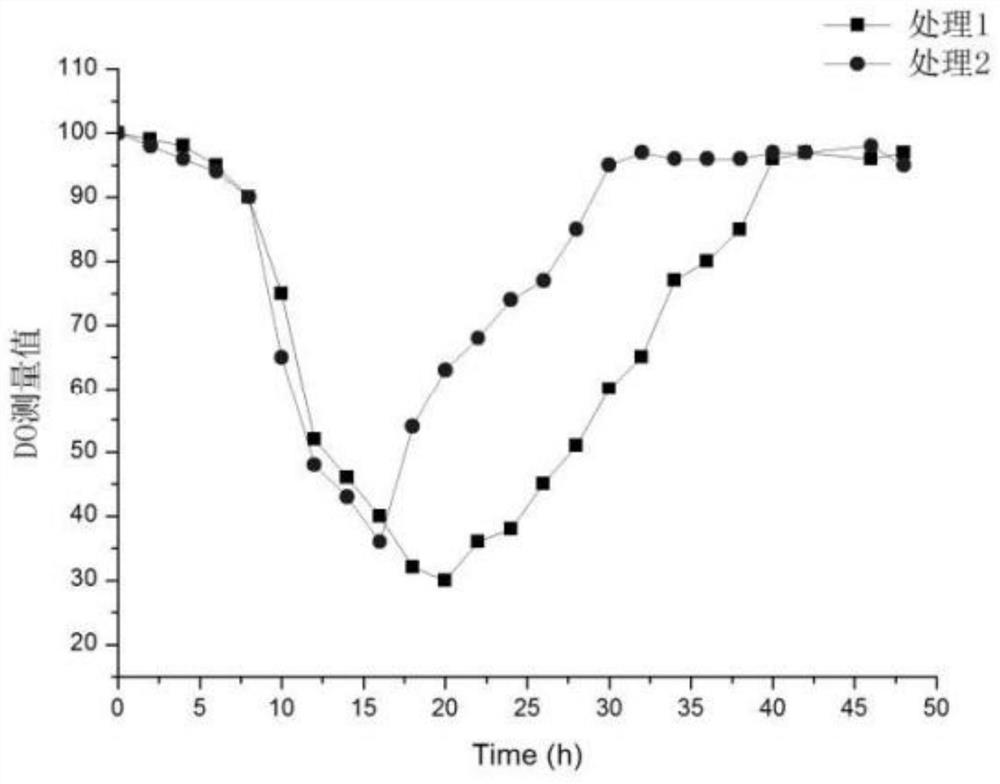

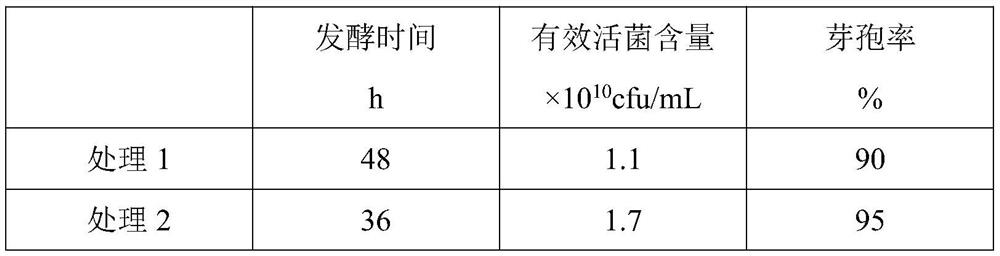

[0052] (4) Fermentation tank high-density fermentation culture: the seed liquid gained in the step (3) is inserted in the 1000L fermentation tank by the inoculum size of 1% after microscopic examination without assorted bacteria pollution, and the fermentation medium composition in the tank: bran 2%, corn flour 1%, yeast extract 0.2%, sodium chloride 0.2%, CaCO30.4%, KH2PO40.06%, magnesium sulfate 0.1%, MnCl20.03%, defoamer 0.015%. Culture conditions: fermentation temperature control: 33°C; air flow adjustment: 0h-4h control at 0.4vvm, 4h-8h control at 0.6vvm, 8h-11h control at 0.8vvm, 11h-36h control at 1.0vvm; stirring adjustment: 0h ~7h is con...

Embodiment 3

[0059] Preparation of Bacillus licheniformis wettable powder:

[0060] (1) Strain activation is the same as in Example 1.

[0061] (2) The preparation of the primary seed solution of the shake flask is the same as in Example 1.

[0062] (3) The preparation of the secondary seed liquid in the seed tank is the same as in Example 1.

[0063] (4) fermentor high-density fermentation culture: the seed liquid gained in the step (3) is inserted in the 1000L fermenter by 5% inoculum size after microscopic examination without assorted bacteria pollution, and the fermentation medium composition in the tank: bran 4%, corn flour 3%, yeast extract 0.4%, sodium chloride 0.5%, CaCO 3 0.8%, KH2PO4 0.12%, magnesium sulfate 0.2%, MnCl 2 0.05%, defoamer 0.025%. Culture conditions: fermentation temperature control: 36°C; air flow adjustment: 0h-4h control at 0.6vvm, 4h-8h control at 0.8vvm, 8h-11h control at 0.9vvm, 11h-36h control at 1.5vvm; stirring adjustment: 0h ~7h is controlled at 80r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com