Heterogeneous Fenton catalyst, and preparation method and application thereof

A catalyst and heterogeneous technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of large dosage of slag and hydrogen peroxide, large fluctuation of treatment efficiency, long reaction time, etc. problems, to achieve the effect of fast treatment of organic sewage, wide application range and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method of heterogeneous Fenton catalyst 1:

[0025] The heterogeneous Fenton catalyst 1 was obtained by mixing sodium thiosulfate and 60-80 mesh sulfur iron slag according to the mass ratio of 1:3.3, grinding them evenly, and then heating at 160°C for 8 hours.

[0026] At a reaction temperature of 25°C, mix the heterogeneous Fenton catalyst 1, hydrogen peroxide, hydroxylamine hydrochloride, and printing and dyeing wastewater containing methylene blue at a pH of 2. After mixing, the content of the heterogeneous Fenton catalyst 1 in the reaction system is 1 g / L, the concentration of hydrogen peroxide is 29mmol / L, the concentration of hydroxylamine hydrochloride is 0.2mmol / L, and the concentration of methylene blue is 50mg / L. The mixture is monitored in real time, and the monitoring results are shown in Table 1:

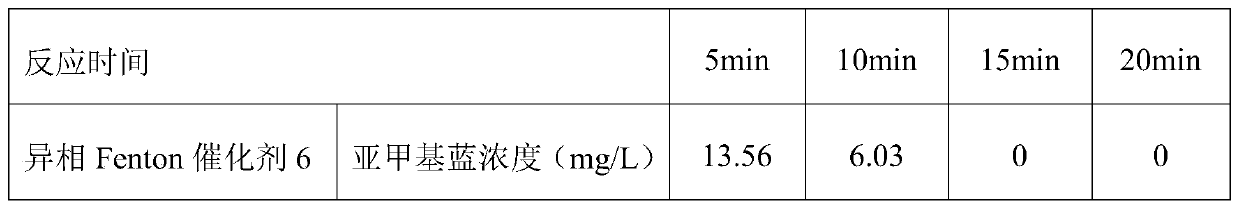

[0027] Table 1

[0028] Reaction time 3min 5min 8min 10min Methylene blue concentration (mg / L) 18.17 8.23 1.44 0 ...

Embodiment 2

[0030] The preparation method of heterogeneous Fenton catalyst 2:

[0031] The heterogeneous Fenton catalyst 2 was obtained by mixing thiourea and 100-140 mesh sulfur iron slag according to the mass ratio of 1:5 and grinding them evenly, and then heating at 140°C for 5 hours.

[0032] At a reaction temperature of 30°C, mix the heterogeneous Fenton catalyst 2, hydrogen peroxide, hydroxylamine sulfate, and printing and dyeing wastewater containing Rhodamine B at a pH of 10. After mixing, the content of the heterogeneous Fenton catalyst 2 in the reaction system 0.5g / L, the concentration of hydrogen peroxide is 5.8mmol / L, the concentration of hydroxylamine sulfate is 1mmol / L, and the concentration of rhodamine B is 20mg / L. The mixture is monitored in real time, and the monitoring results are shown in Table 2:

[0033] Table 2

[0034] Reaction time 10min 30min 50min 70min Rhodamine B concentration (mg / L) 16.51 10.22 6.56 2.10 Rhodamine B decoloriza...

Embodiment 3

[0036] The preparation method of heterogeneous Fenton catalyst 3:

[0037] The heterogeneous Fenton catalyst 3 was prepared by mixing thioacetamide and 260-300 mesh sulfur iron slag according to a mass ratio of 1:1, grinding them evenly, and then heating at 200°C for 10 hours.

[0038] At a reaction temperature of 25°C, mix the heterogeneous Fenton catalyst 3, hydrogen peroxide, ascorbic acid and glucose-containing papermaking wastewater evenly. After mixing, the content of the heterogeneous Fenton catalyst 3 is 3 g / L, and the concentration of hydrogen peroxide is 98mmol / L, the concentration of ascorbic acid is 2mmol / L, the COD of glucose Cr It is 920mg / L. The mixture is monitored in real time, and the monitoring results are shown in Table 3:

[0039] table 3

[0040] Reaction time 20min 30min 40min 50min 60min COD Cr (mg / L)

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com