A kind of preparation method of small size red phosphor

A technology of red fluorescent powder and small size, which can be used in chemical instruments and methods, luminescent materials, etc. It can solve the problems of fluorides such as moisture resistance, poor heat resistance, lively properties, and high requirements for packaging technology, and achieve regular shape and variety. Easy to obtain, the effect of improving the mass transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

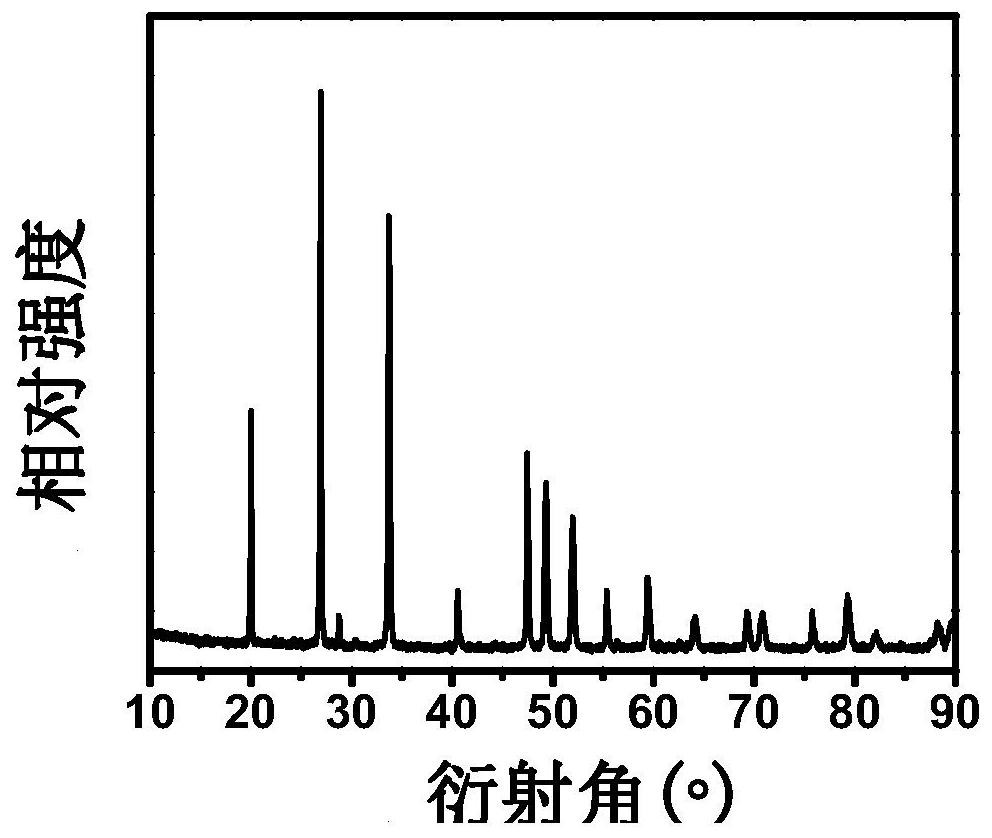

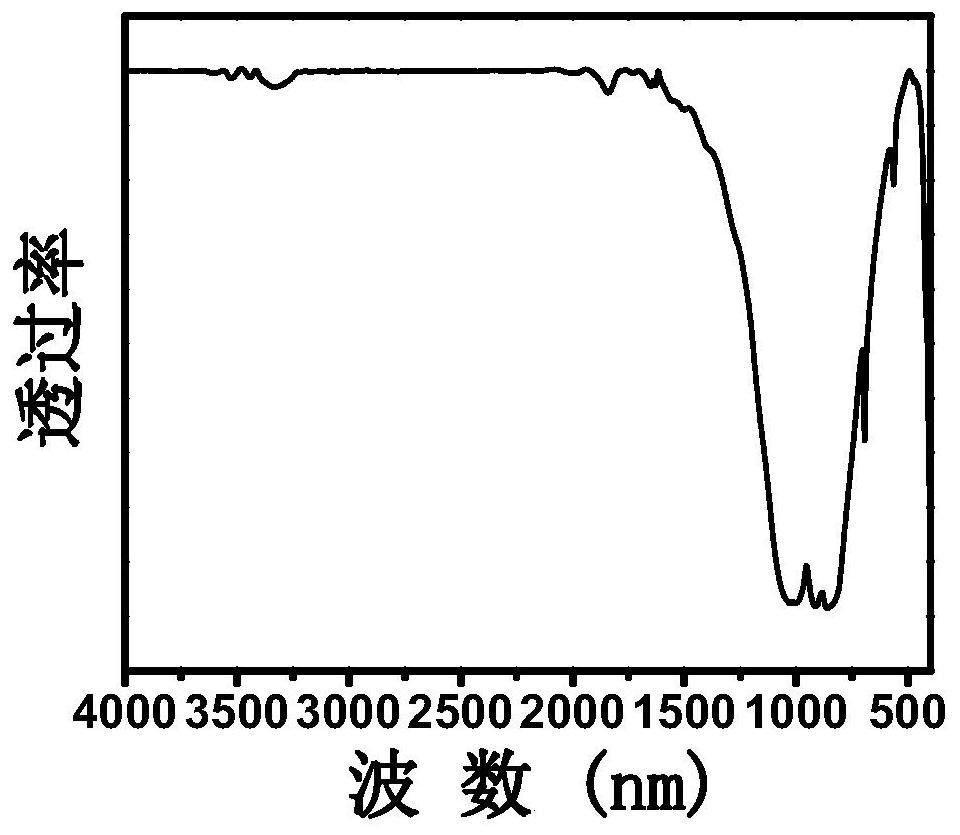

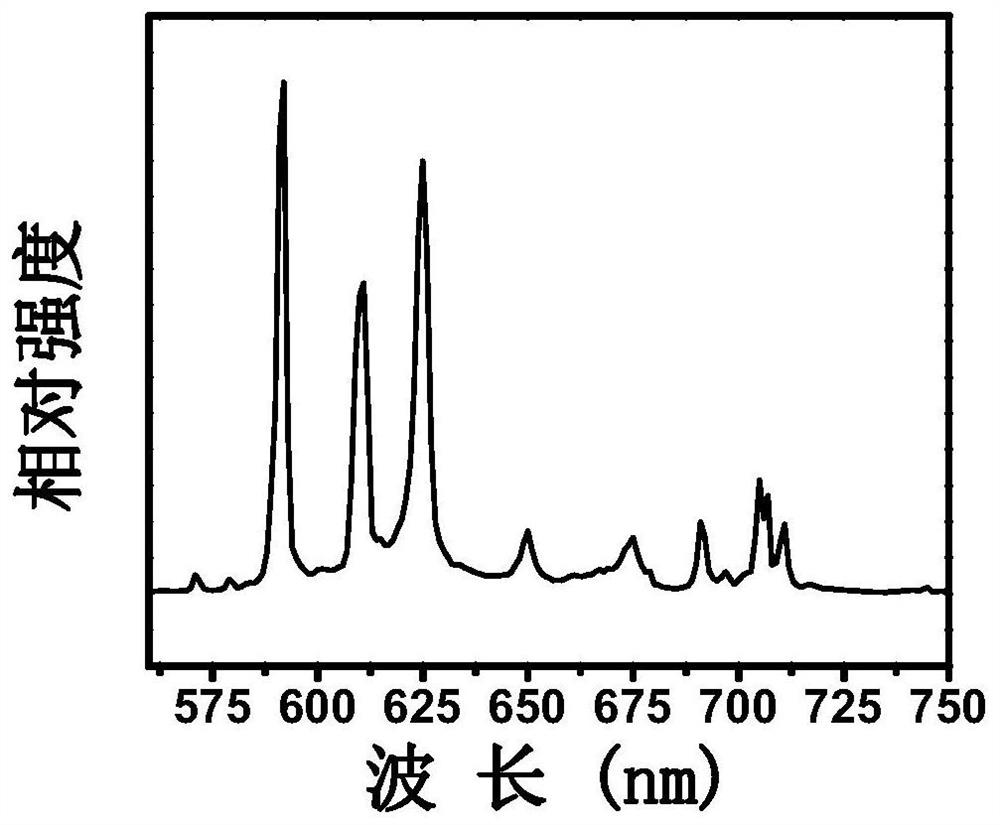

Embodiment 1

[0030] According to the different doping amounts of GdBO3:Eu, weigh corresponding amounts of gadolinium oxide (3.26g), europium oxide (0.352g), boric acid (1.428g), nitric acid (2.84g), surfactant (PEG-1000) (4.43g ), mixed with 100ml of deionized water, put it into a high-gravity rotating packed bed at 2000r / min and mixed thoroughly for 20min; measured 4.32ml of acetylacetone and 36g of urea in a graduated cylinder and mixed them fully, heated at 90°C for 1h; the solution was reduced to After room temperature, the centrifuge was centrifuged at 11000r / min, the product was washed twice with deionized water and absolute ethanol, and then dried in an oven at 80°C for 12 hours; after drying, it was fully ground with a mortar and put into an alumina crucible, muffle Furnace 1200°C heating rate 5°C / min, holding time 4h; after cooling down to room temperature, take out the product and grind it;

Embodiment 2

[0032] According to the different doping amounts of GdBO3:Eu, weigh corresponding amounts of gadolinium oxide (3.26g), europium oxide (0.352g), boric acid (1.428g), nitric acid (2.84g), surfactant (PEG-1000) (4.43g ), take 100ml of deionized water and mix it, put it into a high-gravity rotating packed bed at 2000r / min and mix it thoroughly for 10-50min, take a sample every 10min, and mark 20ml of each sample as 1, 2, 3, 4, 5; Take out the solution measuring cylinder and measure 0.864ml acetylacetone, weigh 7.2g urea and mix it fully with the solution, heat at 90°C for 1 hour; after the solution cools down to room temperature, centrifuge at 11000r / min, wash with deionized water and absolute ethanol twice respectively Dry in an oven at 80°C for 12 hours. After drying, fully grind it with a mortar and put it into an alumina crucible. The heating rate of the muffle furnace is 1200 °C at 5 °C / min, and the holding time is 4 h; when the temperature is lowered to room temperature, the...

Embodiment 3

[0034]According to the different doping amounts of GdBO3:Eu, weigh corresponding amounts of gadolinium oxide (3.26g), europium oxide (0.352g), boric acid (1.428g), nitric acid (2.84g), surfactant (PEG-1000) (4.43g ), mixed with 100ml of deionized water, put into the high-gravity rotating packed bed at 2000r / min and fully mixed for 20min; measure 4.32ml of acetylacetone in a graduated cylinder and mix well, then divide the solution into eight parts, each 25ml part is marked as 2mol / L , 4mol / L, 6mol / L, 8mol / L, 10mol / L Weigh 2.4g, 4.8g, 7.2g, 9.6g, 12g of urea and mix them thoroughly with the solution, heat at 90°C for 1h; after the solution drops to room temperature, centrifuge Centrifuged at 11000r / min, the product was washed twice with deionized water and absolute ethanol, and then dried in an oven at 80°C for 12h. After drying, fully grind it with a mortar and put it into an alumina crucible. The heating rate of the muffle furnace is 1200 °C at 5 °C / min, and the holding time ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com