Miniature spectrum testing system and testing method

A spectral testing and miniature technology, applied in the field of spectral analysis, can solve problems such as limited spectral resolution, low correlation, and narrow working wavelength range, and achieve the effects of enhancing photoelectric conversion, realizing performance, and increasing the working wavelength range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

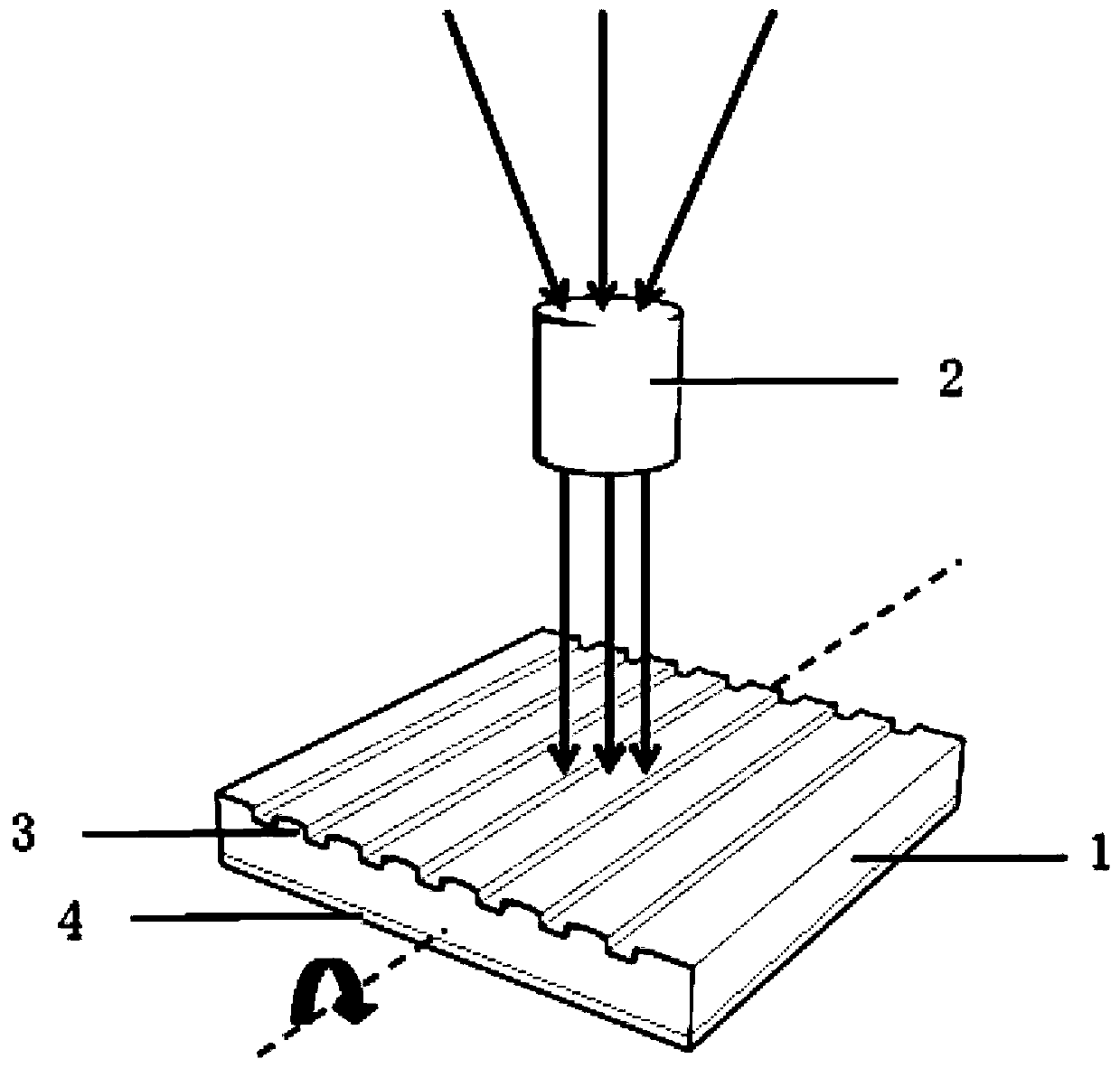

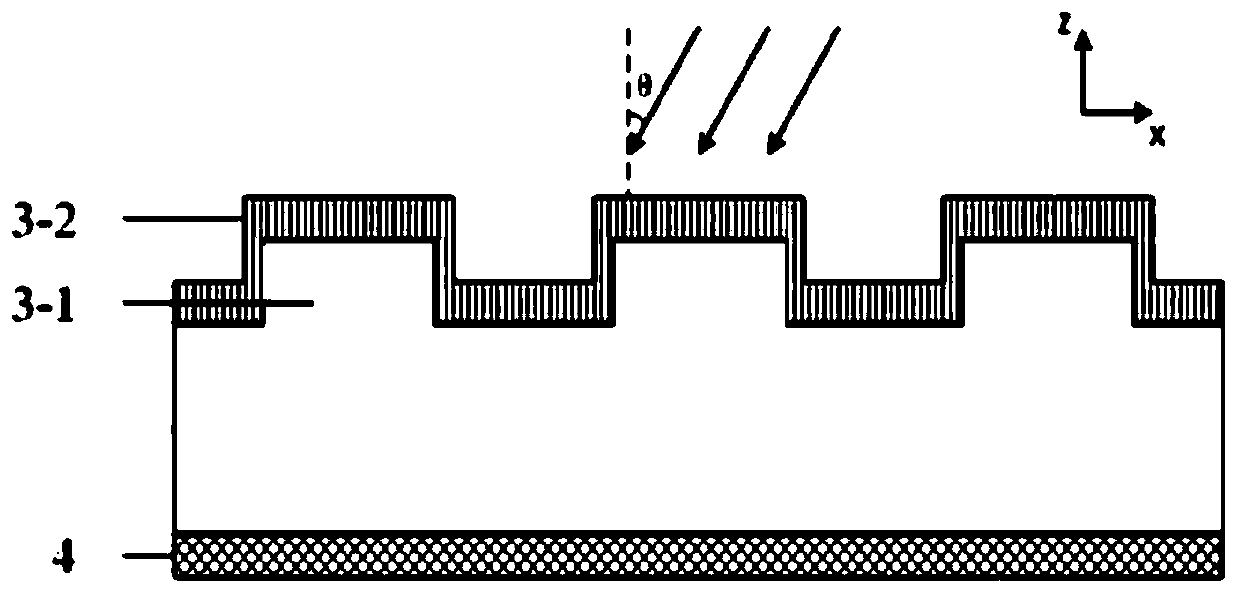

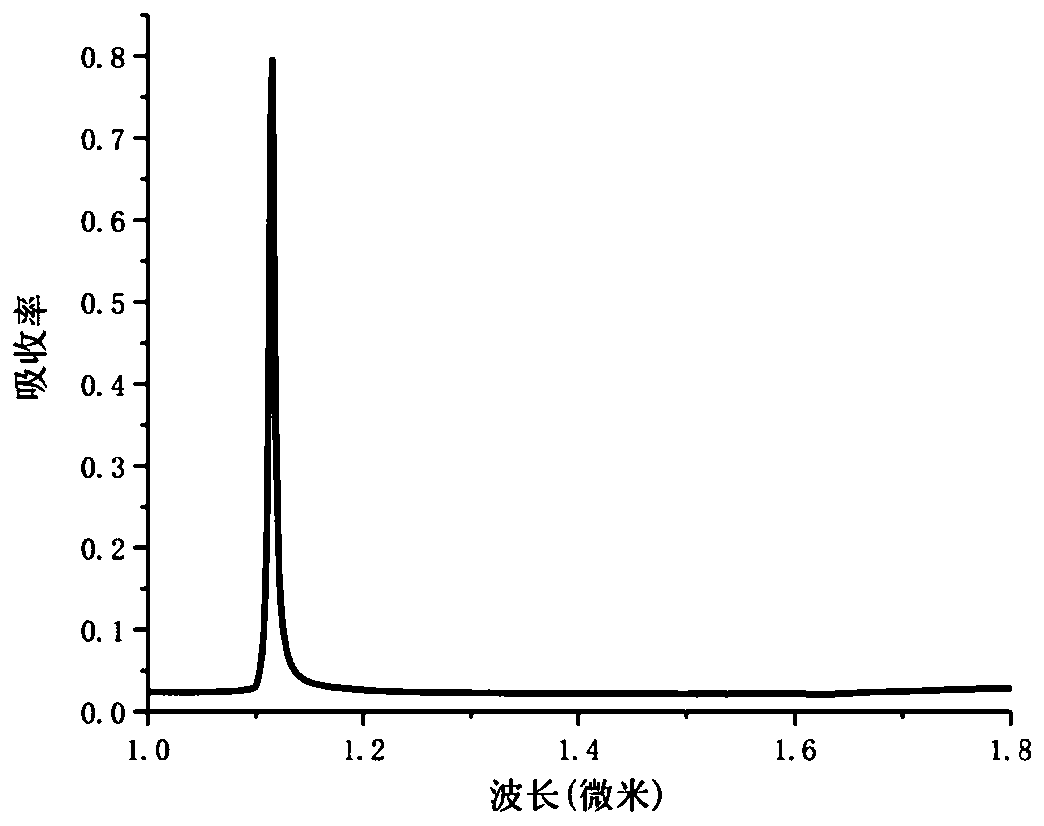

[0042] refer to figure 2 As shown, the present embodiment provides a kind of miniature spectrum testing system, and the first surface of rotatable silicon wafer facing the beam collimation module forms a one-dimensional silicon material grating 3-1, wherein the period is 1.1 microns, and the width of the silicon material grating is 0.5 μm. Micron, the depth of the silicon material grating is 35 nanometers; the silicon material grating is covered with a gold film 3-2 with a thickness of 60 nanometers. The silicon material grating and the gold film together form the grating and form a Schottky junction. The gold film is used as the first electrode of the photodetection module, and the second electrode 4 of the photodetection module is formed on the second surface of the backlight of the silicon wafer, which is gold material. The thickness is 200 nm.

[0043] The incident light of different wavelengths resonates with the surface plasmon wave of the grating at a specific inciden...

Embodiment 2

[0051] Figure 10 It is a schematic cross-sectional structure diagram of the photodetection module of the miniature spectrum testing system of this embodiment. As shown in the figure, the preparation of the photodetection module in this embodiment is by covering the surface of the silicon wafer with a gold film, and then forming a silicon dioxide grating 3-3 on the gold film, wherein the thickness of the gold film is 80 nanometers, and the silicon dioxide grating 3-3 has a depth of 155 nm and a width of 360 nm. Figure 11 It is the calculation result of the absorption spectrum of the photodetection module of this embodiment under normal incident light irradiation. The resonance occurs at a wavelength of 1068 nm, the absorption at the peak is greater than 95%, the full width at half maximum is <10 nm, and the quality factor Q is greater than 100. The formation and working principles of the first and second electrodes are the same as those in the first embodiment.

Embodiment 3

[0053] Figure 12 It is a schematic diagram of the horizontal cross-sectional structure of the two-dimensional grating of the photodetection module of the micro spectrum testing system of this embodiment. In the preparation of the photoelectric detection module in this embodiment, a gold film with a thickness of 180 nanometers is deposited on a silicon wafer, and then a two-dimensional disk array 3-4 is etched on the gold film, the height of the disk is 100 nanometers, and the radius is 500 nanometers. The disc period is 1400 nm. Figure 13 It is the calculation result of the absorption spectrum of the miniature spectrum testing system of this embodiment under normal incident light irradiation. Resonance between incident light and surface plasmon waves occurs at 1412 nm at normal incidence. The absorption at the peak is greater than 98%, and the full width at half maximum is 4 nm. The quality factor Q is as high as 300. The formation and working principles of the first and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com