Inner wall desulfurization gypsum putty

A technology for desulfurizing gypsum and putty, which is applied in the direction of filling slurry, etc., can solve the problems of general purification effect and high cost, and achieve the effect of convenient local trimming, high flatness, and not easy to hollow out.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

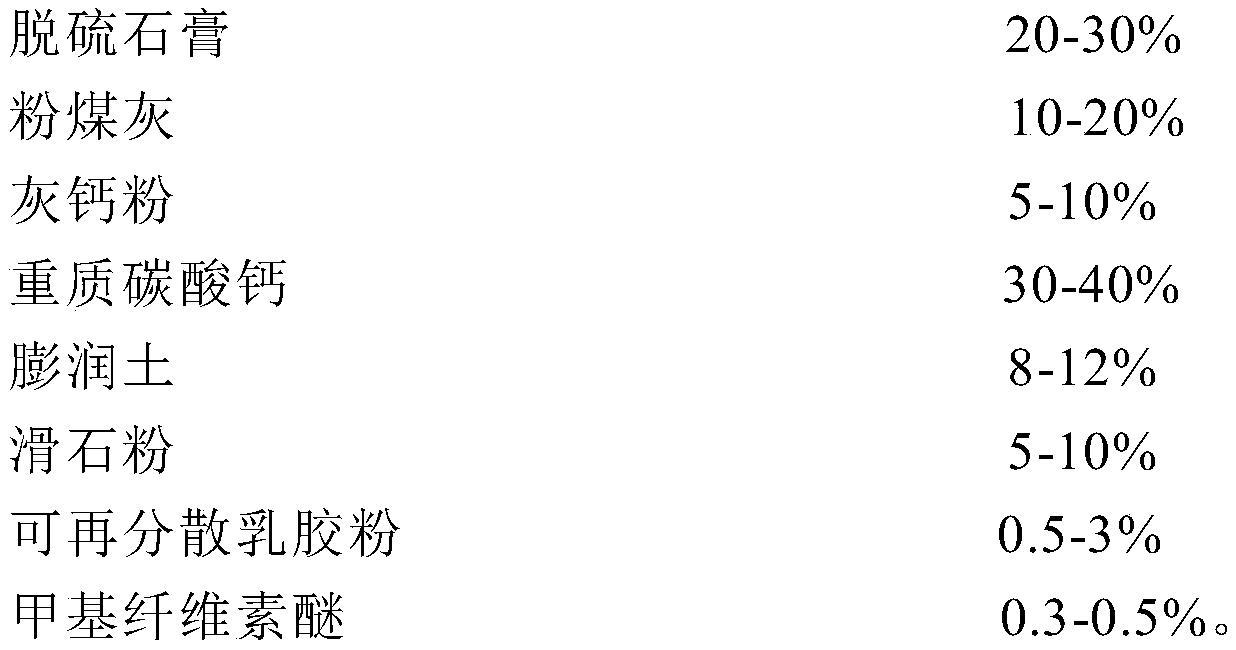

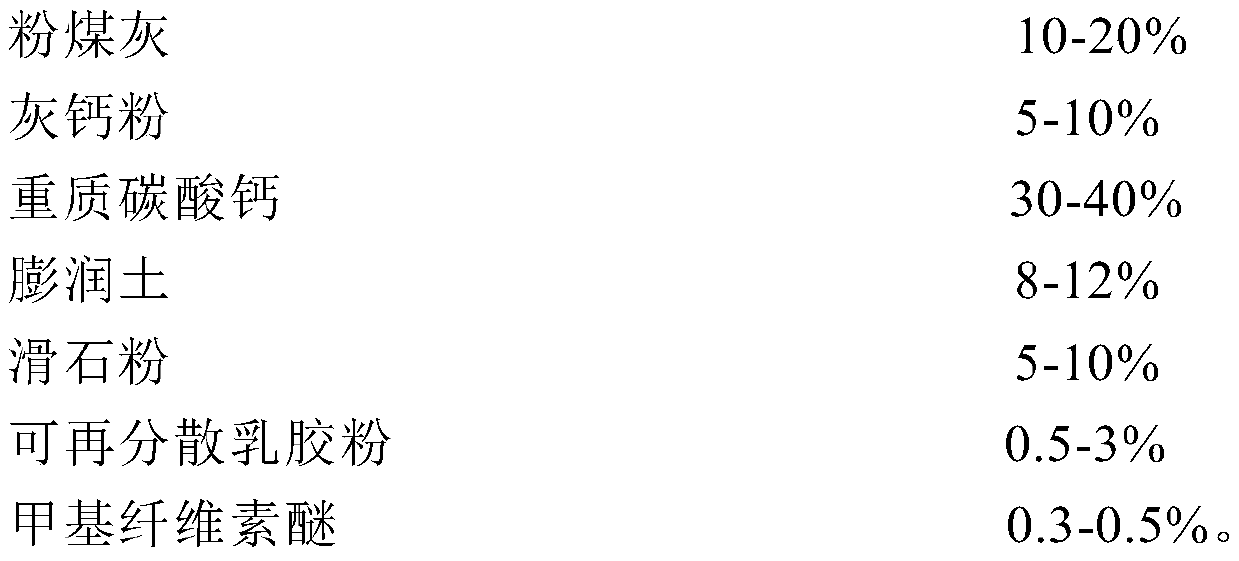

[0030] The interior wall desulfurization gypsum putty of the present embodiment comprises by weight percentage:

[0031] Desulfurization gypsum 25%, fly ash 15%, ash calcium powder 8%, heavy calcium carbonate 32%, bentonite 10%, talcum powder 7.5%, starch ether 0.1%, magnesium aluminum silicate 0.5%, redispersible latex powder 1.5%, methyl cellulose ether 0.4%;

[0032] Among them, desulfurization gypsum and fly ash are the industrial waste residues with large displacement in my country. They have low thermal conductivity and have thermal insulation properties, while the particles of fly ash are porous honeycomb structure with high specific surface area and high specific surface area. Adsorption activity and water absorption;

[0033] Bentonite is sodium-based bentonite with a particle size of 180-325 mesh and a montmorillonite content of ≥80%. It has strong hygroscopicity and expansibility, and can absorb 8 to 15 times its own volume of water, and its volume expansion can rea...

Embodiment 2

[0040] The interior wall desulfurization gypsum putty of the present embodiment comprises by weight percentage:

[0041] Desulfurization gypsum 25%, fly ash 10%, ash calcium powder 5%, heavy calcium carbonate 35%, bentonite 12%, talcum powder 10%, starch ether 0.1%, magnesium aluminum silicate 0.4%, redispersible latex powder 2%, methyl cellulose ether 0.5%;

[0042] Wherein, the particle size of ash calcium powder is 400 mesh; The particle size of ground calcium carbonate is 400 mesh; The particle size of talcum powder is 325 mesh; Redispersible latex powder is acrylate and vinyl acetate 1:1 (weight ratio) mixture, The glass transition temperature is -13°C; the viscosity of methyl cellulose ether is 300cps; the rest of the component materials are the same as in Example 1.

[0043] The preparation method is the same as in Example 1. Do the same project detection with embodiment 1, and the results are shown in Table 1.

Embodiment 3

[0045] The interior wall desulfurization gypsum putty of the present embodiment comprises by weight percentage:

[0046] Desulfurization gypsum 20%, fly ash 20%, ash calcium powder 10%, heavy calcium carbonate 32%, bentonite 8%, talcum powder 6.5%, starch ether 0.1%, magnesium aluminum silicate 0.4%, redispersible latex powder 2.5%, methyl cellulose ether 0.5%;

[0047] Among them, the redispersible latex powder is acrylate, and the glass transition temperature is -14° C.; the viscosity of methyl cellulose ether is 300 cps; the other component materials are the same as in Example 1.

[0048] The preparation method is the same as in Example 1. Do the same project detection with embodiment 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com