Long-working distance plasmon nanolithography method

A working distance and plasmon technology, applied in the field of lithography, can solve the problems of shallow exposure depth, limited exposure distance, and limited wide application, etc., and achieve the effects of high resolution, extended exposure distance, and extended exposure depth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

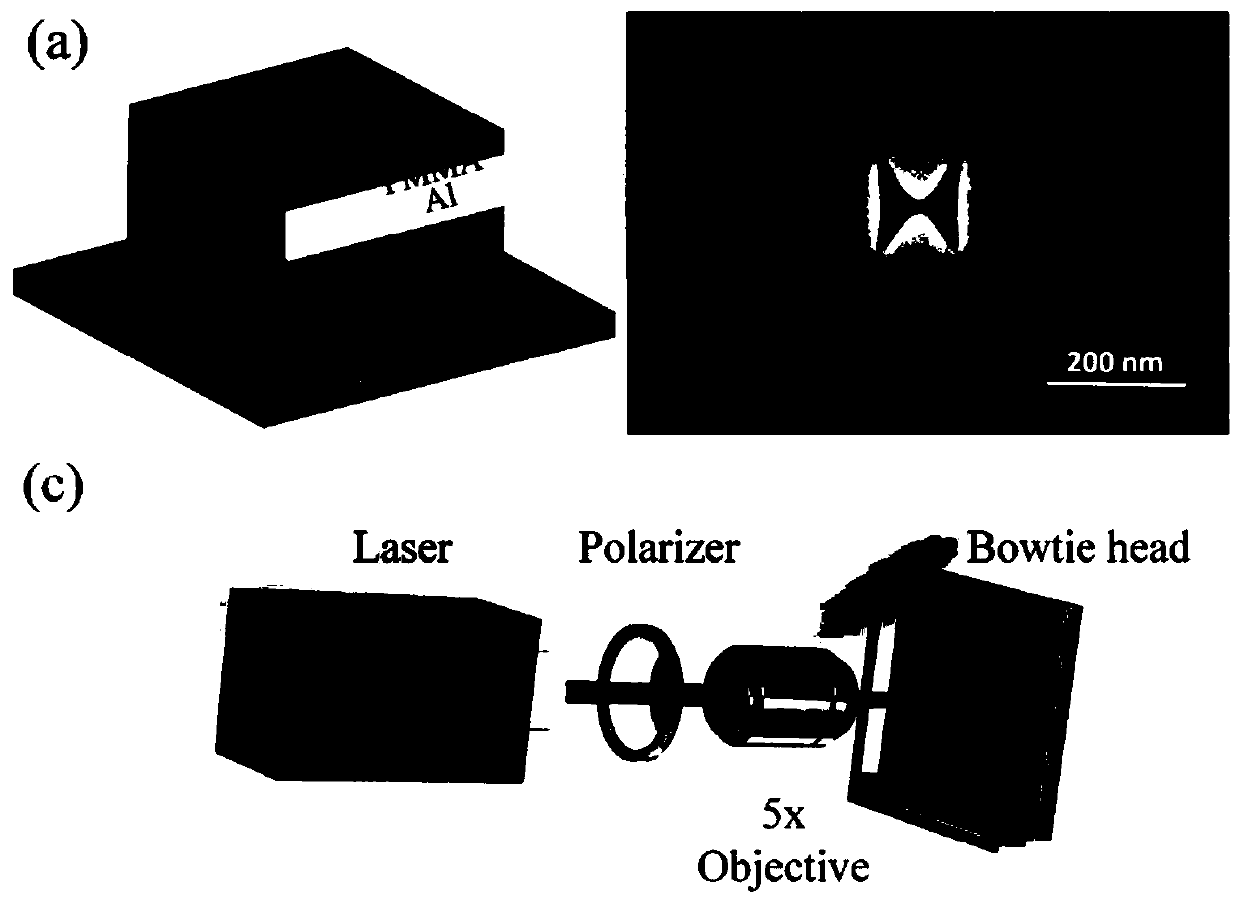

[0043] A) prepare bow tie photolithography head, the preparation method of described bow tie photolithography head comprises:

[0044] a-1) depositing an aluminum film on the first substrate;

[0045] a-2) using a focused ion beam to etch a bow tie structure on the aluminum film as the exposure aperture;

[0046] a-3) spin coating PMMA layer on the aluminum film;

[0047] a-4) depositing the first silver film layer on the PMMA layer to obtain the bow tie lithography head;

[0048] B) prepare exposure substrate, the preparation method of described exposure substrate comprises:

[0049] b-1) depositing a second silver film on a second substrate;

[0050] b-2) spin-coating the photoresist layer on the second silver film to obtain an exposure substrate;

[0051] C) the bow tie lithography head is in close contact with the exposure substrate, that is, the first silver film layer of the bow tie lithography head is in close contact with the photoresist layer of the exposure subst...

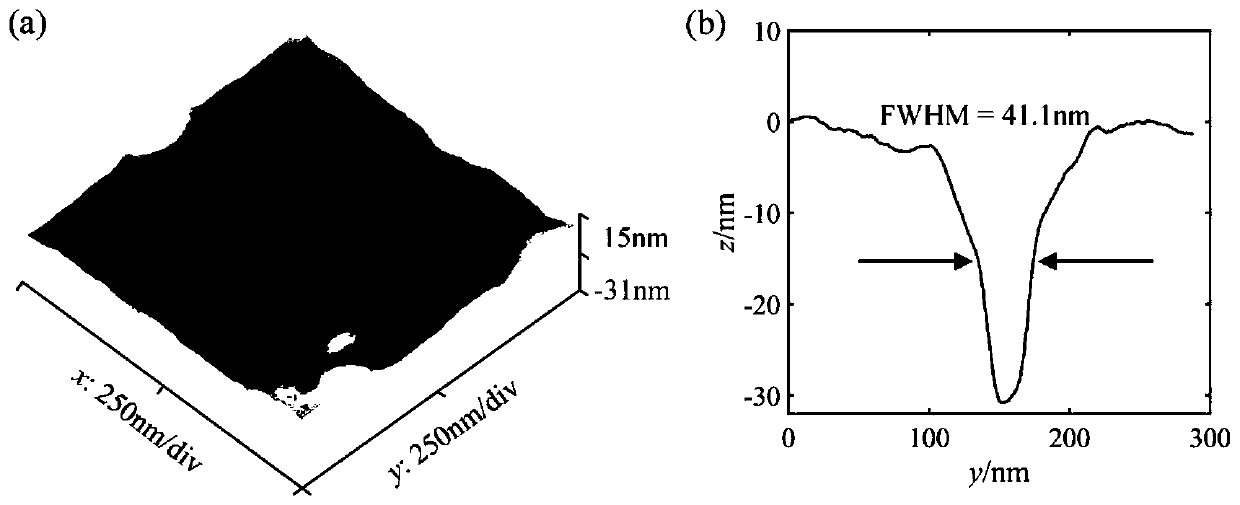

Embodiment 1

[0105] 1) Preparation of "bow tie lithography head"

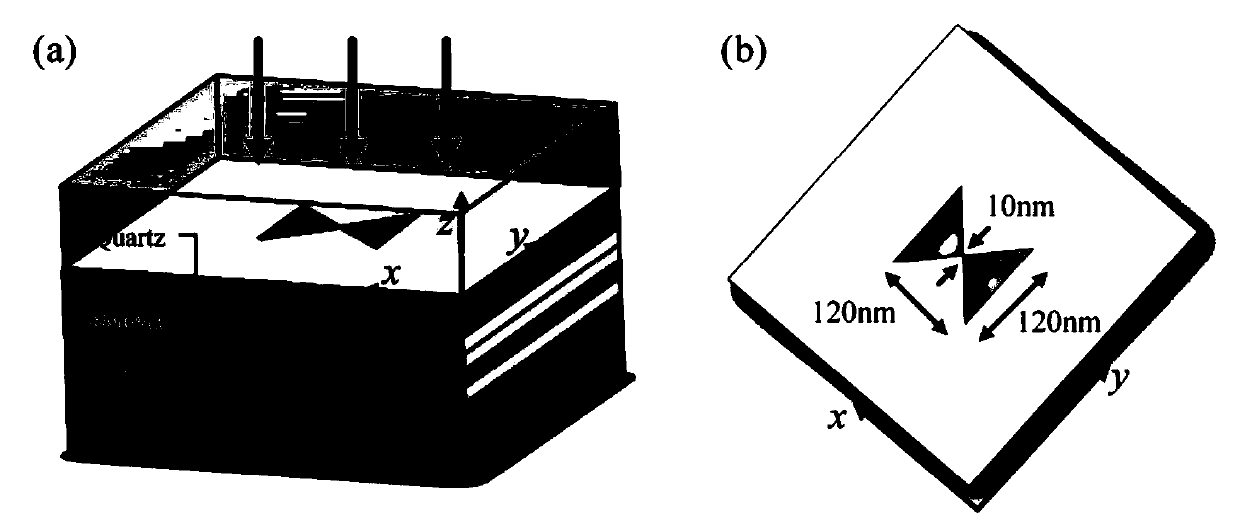

[0106] a) Using the chromium layer (sputter coating, 100nm) as a mask, the step structure on the quartz substrate was obtained by wet etching (as attached figure 2 shown), its typical size is 300 μm × 300 μm × 50 μm.

[0107] b) On the basis of the above steps, deposit an aluminum layer (sputter coating, 100nm) on the substrate;

[0108] c) On the basis of the above steps, use focused ion beam (focus ion beam, FIB) to etch a bow tie structure on the aluminum film as the exposure aperture, the typical size of which is 120nm×120nm, and the distance between the sharp corners of the aperture is 10nm;

[0109] D) on the basis of the above steps, spin coat the PMMA layer (20nm) on the aluminum film;

[0110] e) On the basis of the above steps, deposit the first silver layer (sputter coating, 20nm) on the PMMA layer.

[0111] 2) "Exposure substrate" preparation

[0112] a) preparing the substrate (such as a silicon substrate)...

Embodiment 2

[0128] 6) Preparation of "bow tie lithography head"

[0129] f) Using the chromium layer (sputter coating, 100nm) as a mask, obtain the step structure on the quartz substrate by wet etching (as attached figure 2 shown), its typical size is 300 μm × 300 μm × 50 μm.

[0130] g) On the basis of the above steps, deposit an aluminum layer (sputter coating, 100nm) on the substrate;

[0131] h) On the basis of the above steps, use focused ion beam (focus ion beam, FIB) to etch a bow tie structure on the aluminum film as the exposure aperture, the typical size of which is 120nm×120nm, and the distance between the sharp corners of the aperture is 10nm;

[0132] i) on the basis of the above steps, spin coat the PMMA layer (20nm) on the aluminum film;

[0133] j) On the basis of the above steps, deposit a first silver layer (sputter coating, 20 nm) on the PMMA layer.

[0134] 7) "Exposure substrate" preparation

[0135] e) preparing a substrate (such as a silicon dioxide substrate);...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com