EHS sound insulation board used for building materials and preparation method thereof

A technology of building materials and sound insulation panels, applied in the field of building materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

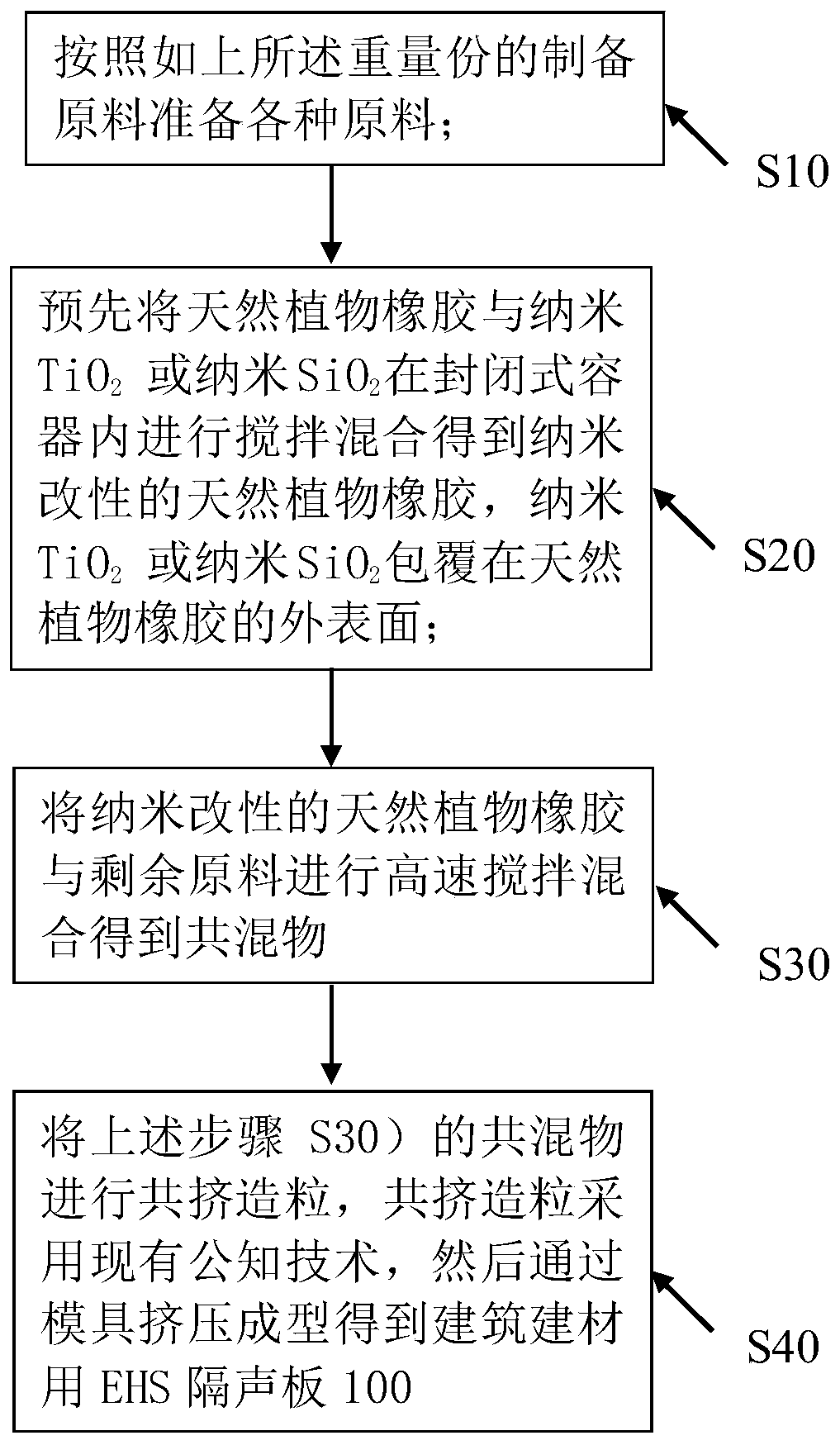

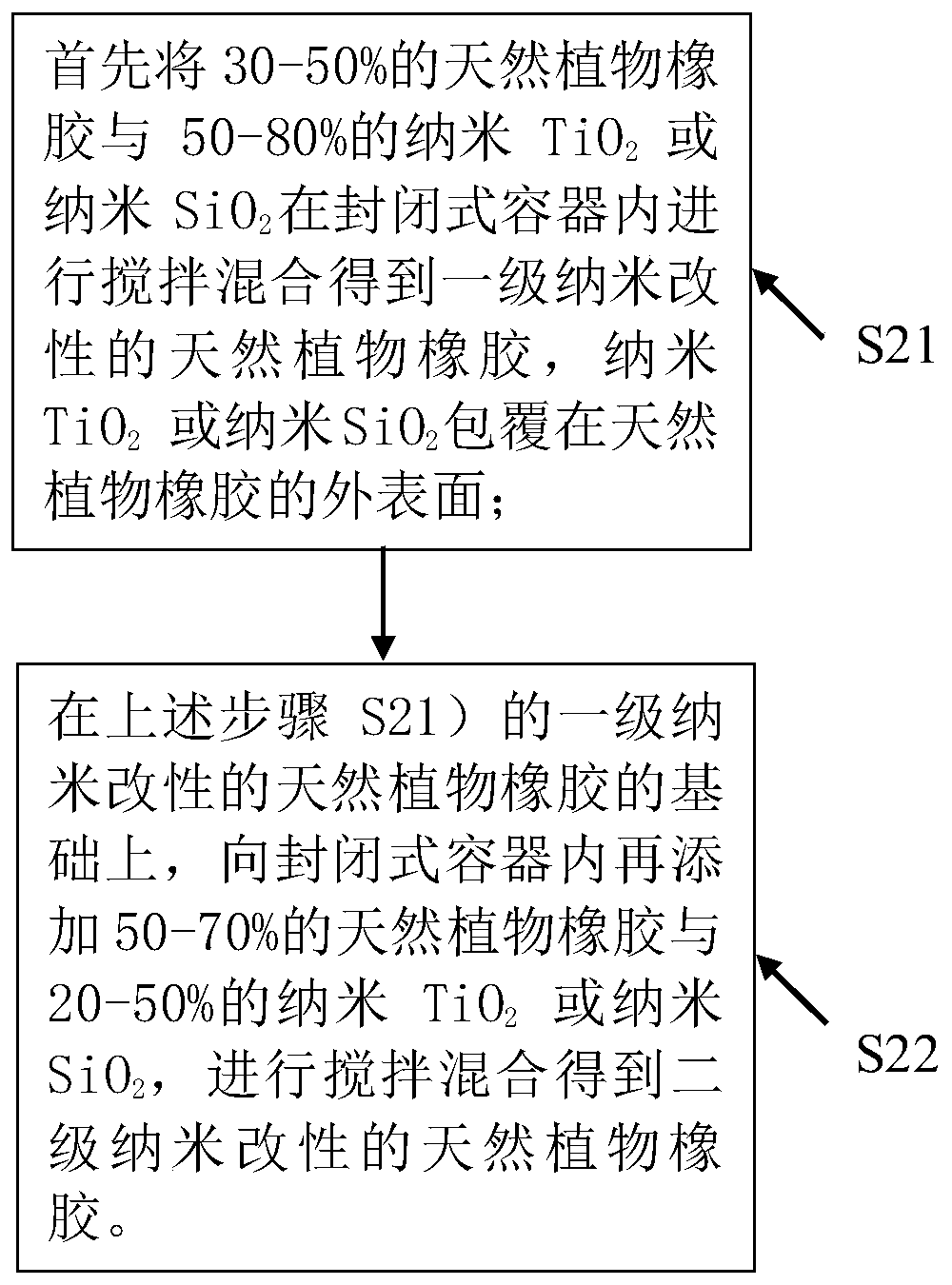

[0036] The embodiment of the present invention also discloses a preparation method of an EHS sound insulation board for building materials, and its operation steps are as follows: S10), prepare various raw materials according to the preparation raw materials of claim 1 weight part; S20), pre-mix the natural plant rubber with nano TiO 2 or nano-SiO 2 Stirring and mixing in a closed container to obtain nano-modified natural plant rubber, nano-TiO 2 or nano-SiO 2 Coating on the outer surface of natural plant rubber; S30), stirring and mixing the nano-modified natural plant rubber and the remaining raw materials at a high speed, and the stirring temperature range is 100-140°C to obtain a blend; S40), combining the above steps S30) Co-extruded granulation of the blend, and then extruded through a die to obtain the EHS sound insulation board for building materials.

[0037]In the embodiment of the present invention, the nano-modification technology is creatively adopted for the f...

Embodiment 1

[0055] Embodiment 1: A kind of EHS sound insulation board for building materials, thickness is 50mm, present embodiment comprises the preparation raw material of following weight part:

[0056] 50 parts of natural vegetable rubber;

[0057] Nano-TiO 2 8 copies;

[0058] 4 parts of emery whose surface is coated with thermoplastic polypropylene, wherein thermoplastic polypropylene accounts for 40% of the emery by weight;

[0059] Foaming agent 5 parts;

[0060] 20 parts of carbon black filler;

[0061] 7 parts glass fiber;

[0062] 6 parts of plasticizer.

[0063] The present embodiment also proposes the preparation method of the EHS sound insulation board for building materials as mentioned above, and its operation steps are as follows:

[0064] S10), preparing various raw materials according to the preparation raw materials in parts by weight as described above;

[0065] S20), the natural plant rubber and nano-TiO 2 Stirring and mixing in a closed container to obtain ...

Embodiment 2

[0070] Embodiment 2: the remaining technical solutions of this embodiment 2 are the same as embodiment 1, the difference is that in this embodiment 2, nano-SiO is used 2 , Micron wear-resistant particles using boron carbon compounds, using titanium dioxide filler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com