Porous alumina ceramic plate, and preparation method thereof

A porous alumina, ceramic plate technology, applied in ceramic products, other household appliances, applications, etc., can solve the problems of rough surface, easy to drop particles, cracking of ceramic sheets, etc., and achieve uniform internal compactness, uniform size distribution, and smoothness. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

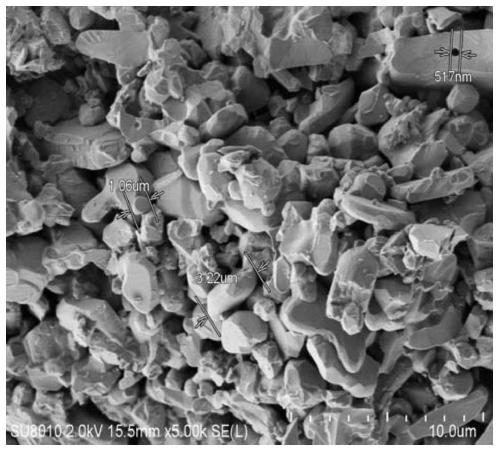

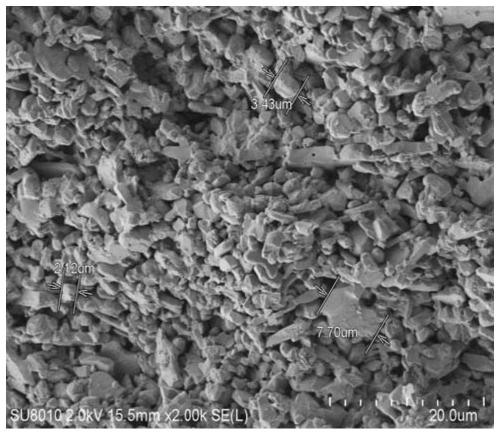

Image

Examples

Embodiment 1

[0036] An embodiment of the porous alumina ceramic plate of the present invention, the porous alumina ceramic plate described in this embodiment is prepared by the following preparation method:

[0037] (1) Preparation of slurry: In parts by weight, weigh 99 parts of alumina powder, add 85 parts of a mixed solvent of butanone and ethanol (1:1), and 2 parts of triolein. Use a planetary ball mill at 400 rpm for 12 hours to mix evenly, then add 6 parts of polyvinyl butyral binder, 5 parts of dibutyl phthalate plasticizer, and then use The planetary ball mill was ball milled for 24 hours under the condition of 400 r / min to mix evenly, and then sieved through a 100-mesh sieve.

[0038] (2) Tape casting: the slurry after ball milling was stirred in vacuum for 2 hours, the stirring speed was 40rpm / min, the viscosity of the slurry was controlled at 15000mPa. The blank thickness is 0.7mm, and the cutting width is 140mm. The blank roll is cut again, and cut into a green body with a si...

Embodiment 2

[0041] An embodiment of the porous alumina ceramic plate of the present invention, the porous alumina ceramic plate described in this embodiment is prepared by the following preparation method:

[0042] (1) Preparation of slurry: in parts by weight, put 98 parts of alumina powder, 1 part of sintering aid (zirconia), 90 parts of solvent (acetone), and 1 part of dispersant (oleic acid) in a planetary ball mill 10 hours at a speed of 530 rpm; then 6 parts of a plasticizer (dioctyl phthalate) and 5 parts of a binder (acrylic resin) were added, and ball milled at a speed of 530 rpm for 12 hours. Sieve through a 100-mesh sieve to obtain a slurry.

[0043] (2) Tape casting: the slurry after ball milling is vacuum stirred for 2.5 hours, the stirring speed is 40rpm / min, the viscosity of the slurry is controlled at 20000mPa.s, and then cast on the casting machine, the blade height is 1.5mm, and the casting speed 0.4m / min, the thickness of the obtained green body is 0.7mm, and the cutti...

Embodiment 3

[0046] An embodiment of the porous alumina ceramic plate of the present invention, the porous alumina ceramic plate described in this embodiment is prepared by the following preparation method:

[0047] (1) Preparation of slurry: in parts by weight, 99.6 parts of alumina powder, 0.2 parts of sintering aid (magnesia, yttrium oxide mixed at a mass ratio of 1:1), 85 parts of solvent (terpineol), dispersed Place 2 parts of plasticizer (phosphate grease) in a planetary ball mill and ball mill for 25 hours at a speed of 400 rpm; then add 8 parts of plasticizer (phthalate) and 9 parts of binder (phenolic resin) , ball milled at a speed of 100 rpm for 25 hours, and sieved through a 100-mesh sieve to obtain a slurry.

[0048] (2) Tape casting: the slurry after ball milling is stirred in vacuum for 1 hour, the stirring speed is 30rpm / min, the viscosity of the slurry is controlled at 10000mPa.s, and then cast on the casting machine, the blade height is 0.5mm, and the casting speed 0.1m / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com