Preparation method of polyacrylamide for incense making adhesive

A technology of polyacrylamide and acrylamide, which is applied in the direction of gasification substances, can solve the problems of high price, unfavorable environmental protection, and difficult to obtain plant adhesives, and achieves the effects of strong adhesion and low moisture absorption rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

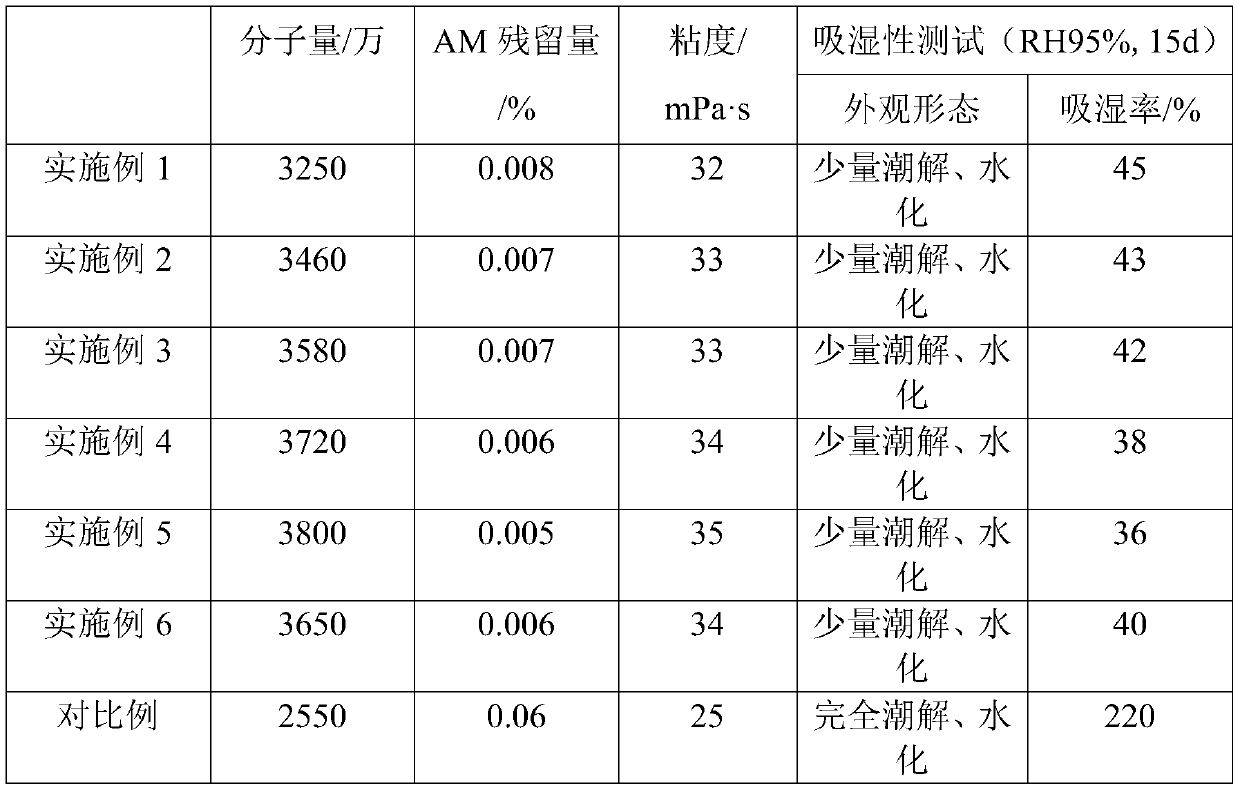

Examples

Embodiment 1

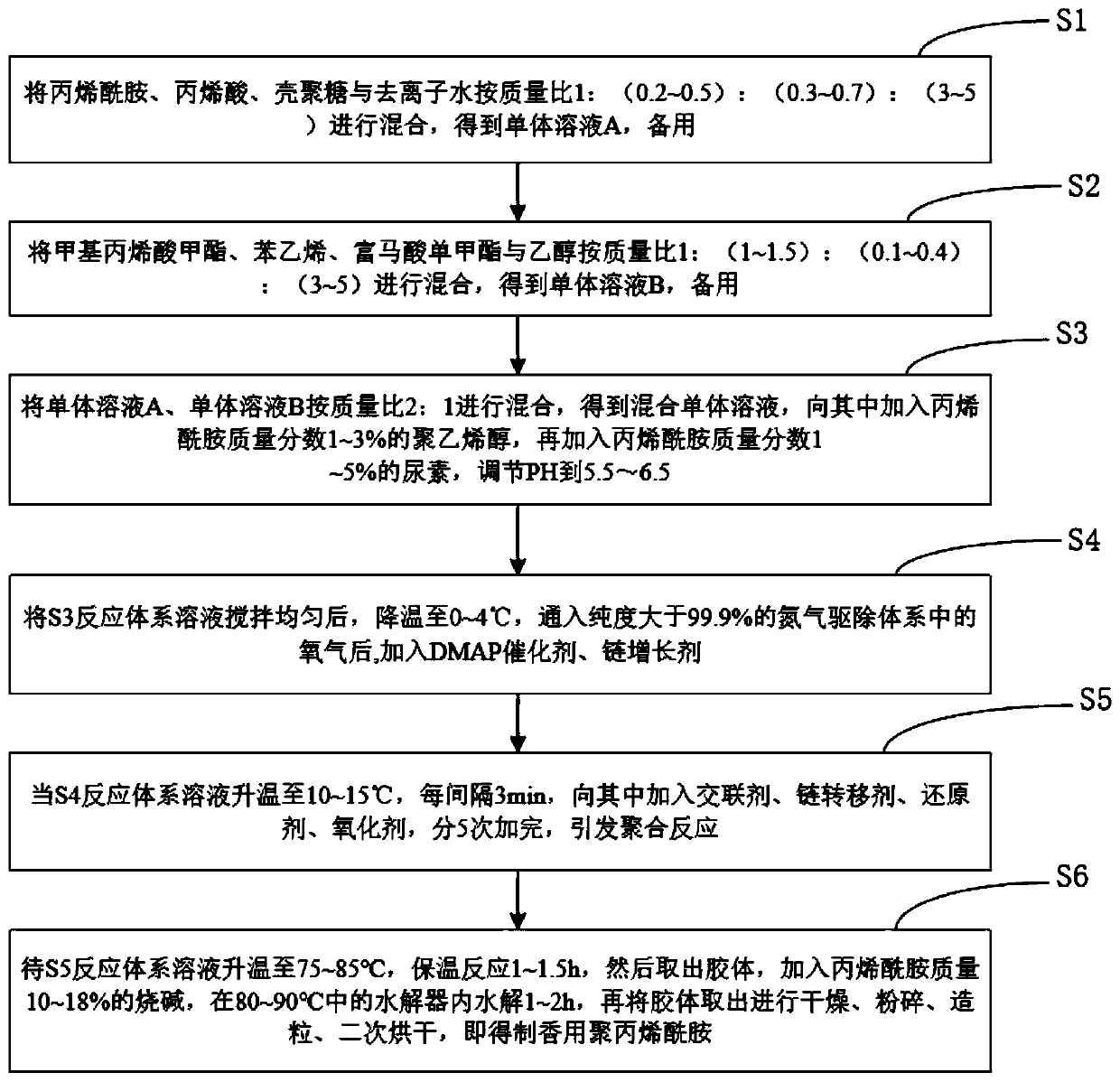

[0031] A preparation method of polyacrylamide for making fragrance adhesives, comprising the following steps:

[0032] S1: Mix acrylamide, acrylic acid, chitosan and deionized water at a mass ratio of 1:0.2:0.3:3 to obtain monomer solution A for later use;

[0033] S2: Mix methyl methacrylate, styrene, monomethyl fumarate and ethanol at a mass ratio of 1:1:0.1:3 to obtain a monomer solution B for later use;

[0034] S3: Mix the monomer solutions A and B at a mass ratio of 2:1 to obtain a mixed monomer solution, add polyvinyl alcohol with a mass fraction of 1% acrylamide to it, and then add urea with a mass fraction of 1% acrylamide to adjust PH to 5.5;

[0035] S4: After the S3 reaction system solution was stirred evenly, the temperature was lowered to 0°C, nitrogen gas with a purity greater than 99.9% was introduced to drive off the oxygen in the system, and then 0.02% of the mass of the mixed monomer solution in S3 was added. DMAP catalyst, the mixed monomer solution in S3 ...

Embodiment 2

[0039] A preparation method of polyacrylamide for making fragrance adhesives, comprising the following steps:

[0040] S1: Mix acrylamide, acrylic acid, chitosan and deionized water at a mass ratio of 1:0.3:0.4:3.5 to obtain monomer solution A for later use;

[0041] S2: Mix methyl methacrylate, styrene, monomethyl fumarate and ethanol at a mass ratio of 1:1.1:0.2:3.5 to obtain a monomer solution B for later use;

[0042] S3: Mix the monomer solutions A and B at a mass ratio of 2:1 to obtain a mixed monomer solution, add polyvinyl alcohol with a mass fraction of 1.5% of acrylamide to it, and then add urea with a mass fraction of 2% of acrylamide to adjust PH to 5.5;

[0043] S4: After the S3 reaction system solution was stirred evenly, the temperature was lowered to 1°C, nitrogen gas with a purity greater than 99.9% was introduced to drive off the oxygen in the system, and 0.03% of the mass of the mixed monomer solution in S3 was added. DMAP catalyst, the mixed monomer soluti...

Embodiment 3

[0047] A preparation method of polyacrylamide for making fragrance adhesives, comprising the following steps:

[0048] S1: Mix acrylamide, acrylic acid, chitosan and deionized water at a mass ratio of 1:0.4:0.5:4 to obtain monomer solution A for later use;

[0049] S2: Mix methyl methacrylate, styrene, monomethyl fumarate and ethanol at a mass ratio of 1:1.2:0.3:4 to obtain a monomer solution B for later use;

[0050] S3: Mix the monomer solutions A and B at a mass ratio of 2:1 to obtain a mixed monomer solution, add polyvinyl alcohol with a mass fraction of 2% of acrylamide to it, and then add urea with a mass fraction of 3% of acrylamide to adjust pH to 6.0;

[0051] S4: After the S3 reaction system solution was stirred evenly, the temperature was lowered to 2°C, nitrogen gas with a purity greater than 99.9% was introduced to drive off the oxygen in the system, and then 0.04% of the mass of the mixed monomer solution in S3 was added. DMAP catalyst, the mixed monomer solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com