White carbon black carbon nanotube composition as well as gas-phase in-situ preparation process and application thereof

A carbon nanotube, in-situ preparation technology, applied in the direction of carbon nanotubes, nanocarbon, nanotechnology, etc., can solve the problems of lack of effective conductive agent, insufficient bonding, unsatisfactory effect, etc., to improve the problem of static electricity accumulation, improve The effect of market competitiveness and ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

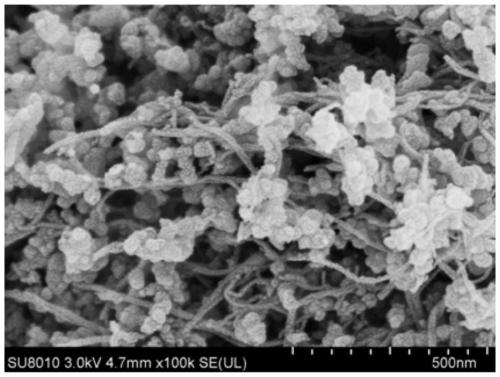

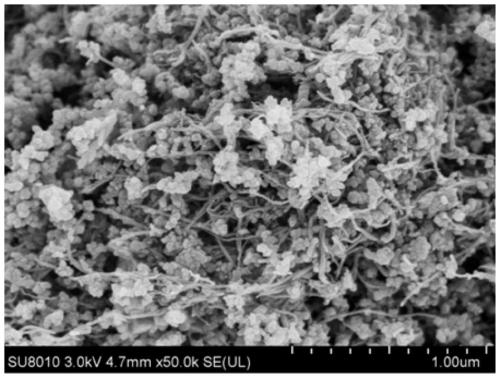

[0036] Such as figure 1 , figure 2 Shown, a kind of white carbon black carbon nanotube compound, this white carbon black carbon nanotube compound adopts the in-situ preparation process of vapor phase method to make, and described process comprises the following steps:

[0037] (1) Carry out preheat treatment to silicon tetrachloride, hydrogen, air, ferrocene and methane respectively;

[0038] (2) The reactor is heated to 950-980°C under nitrogen gas atmosphere, and the preheated silicon tetrachloride, hydrogen, air, ferrocene and methane are in gaseous form according to the molar ratio of 1:20:8:1.8:8 The ratio is passed into the reactor, and the compound is formed through high-temperature hydrolysis and chemical vapor deposition reaction, and the reaction time is 60 minutes;

[0039] (3) the complex is discharged from the reactor through nitrogen positive pressure and then sent to the cooling tank to cool down;

[0040] (4) After the composite was cooled to room temperatu...

Embodiment 2

[0043] A white carbon black carbon nanotube composite, the white carbon black carbon nanotube composite is prepared by a gas-phase in-situ preparation process, and the process comprises the following steps:

[0044] (1) Carry out preheat treatment to silicon tetrachloride, silicon tetrachloride, hydrogen, air, ferrocene and propane respectively;

[0045] (2) The reactor is heated to 1050-1100°C in an argon gas atmosphere, and the preheated silicon tetrachloride, silicon tetrafluoride, hydrogen, air, ferrocene and propane are in gaseous form at a ratio of 1:1:30 : The molar ratio of 10:0.9:5 is passed into the reactor, and a complex is formed through high-temperature hydrolysis and chemical vapor deposition reaction, and the reaction time is 105min;

[0046] (3) The complex is discharged from the reactor through the positive pressure of argon and then sent to the cooling tank to cool down;

[0047](4) After the compound was cooled to room temperature, it was wet granulated and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com