Method for synthesizing cyclopeptide drug carbetocin

A technology of carbetocin and synthesis method, which is applied in the field of synthesis of cyclic peptide drug carbetocin, can solve the problems of high consumption of reagents, reduction of product purity and use effect, and generation of impurities, so as to increase the total income Efficiency and product purity, research on reducing process impurities, and the effect of reducing the types of by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

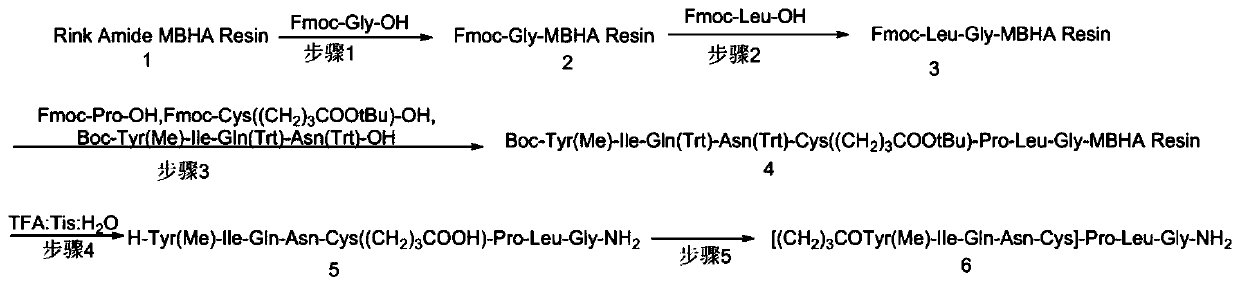

Method used

Image

Examples

Embodiment 1

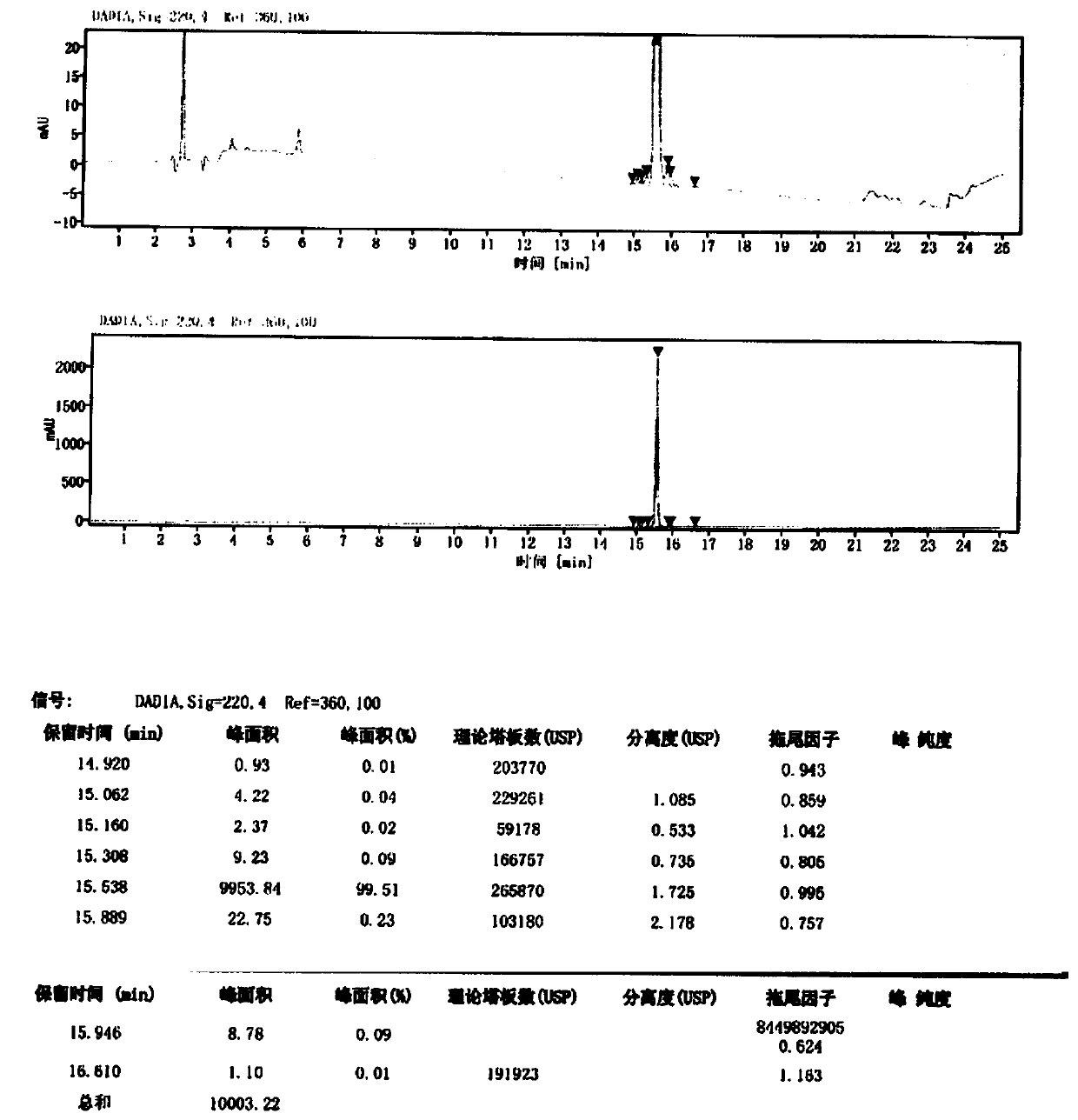

[0044] Screen different substitution degrees Rink Amide MBHA Resin

[0045] Step 1: Synthesis of Fmoc-Gly-MBHA Resin

[0046] Reaction vial 1: Weigh 10.011 g of Rink Amide MBHA Resin with a substitution degree of 0.4 mmol / g, add it to a solid-phase reaction column, and swell the resin with DMF (100 ml) for 30 minutes. The Fmoc protection was deprotected twice with DBLK (20% piperidine / DMF, 100 ml) for 10 minutes, then washed 6 times with DMF (100 ml). Weigh 2.381g of Fmoc-Gly-OH (8.0mmol) and 1.083g of HOBt (8.0mmol) and dissolve in DMF (80ml) solution, add 3.040g of HBTU (8.0mmol) and DIEA (2ml) under ice cooling to activate After 10 minutes, it was added to a solid-phase reaction column and reacted at room temperature for 2 hours. Washed with DMF (100ml) 6 times, sucked dry and directly used in the next reaction.

[0047] Reaction bottle 2: use 6.668g of Rink AmideMBHA Resin with a substitution degree of 0.6mmol / g as the raw material, and use the same method as above to d...

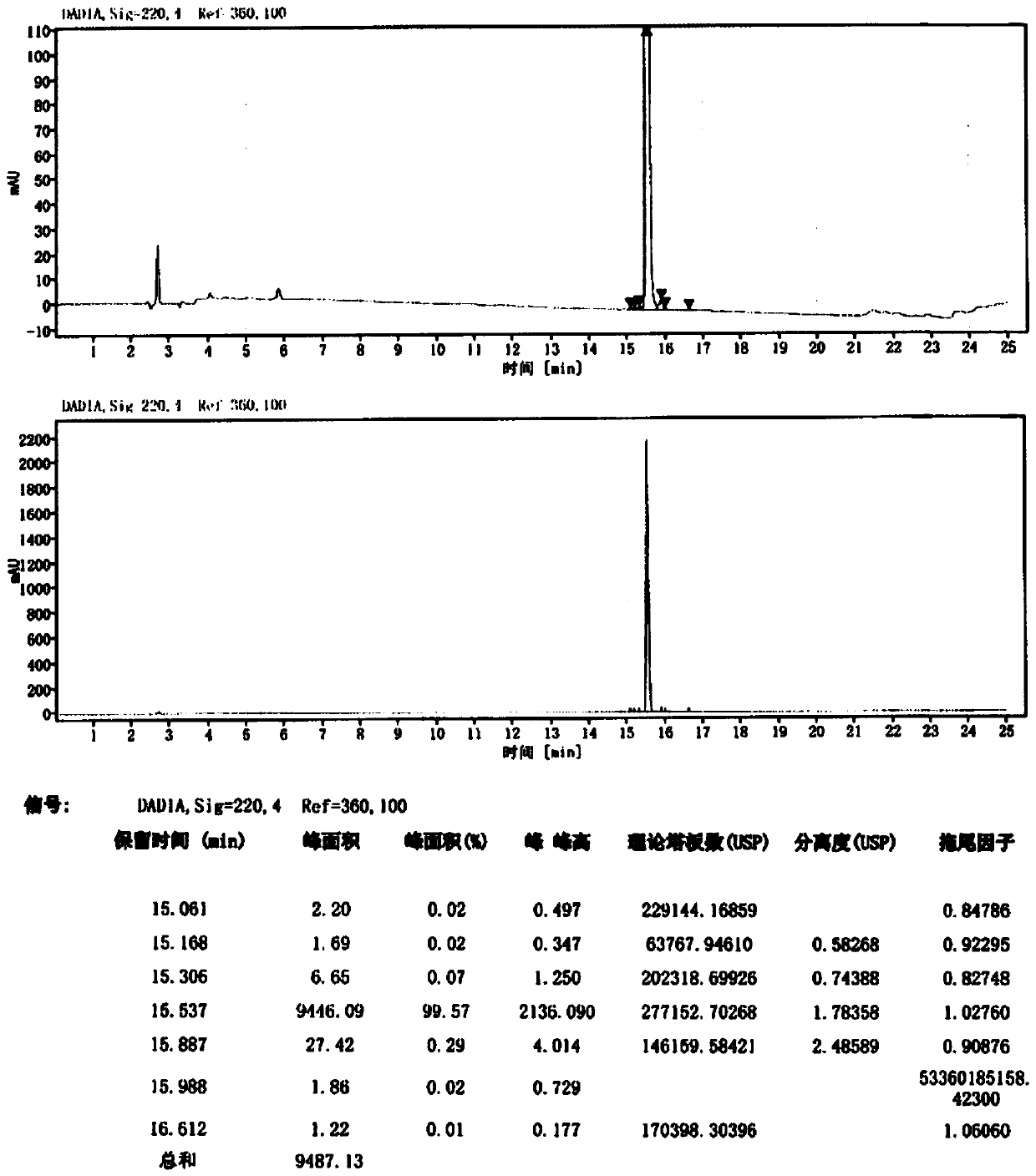

Embodiment 2

[0062] Embodiment 2: Resin type screening

[0063] Step 1: Synthesis of Fmoc-Gly-MBHA Resin

[0064] Reaction bottle 1: Weigh 4.008g of Rink Amide MBHA Resin with a substitution degree of 1.0mmol / g, add it to the solid-phase reaction column, and swell the resin with DMF (100ml) for 30 minutes. The Fmoc protection was deprotected twice with DBLK (20% piperidine / DMF, 100 ml) for 10 minutes, then washed 6 times with DMF (100 ml). Weigh 2.379g of Fmoc-Gly-OH (8.0mmol) and 1.081g of HOBt (8.0mmol) and dissolve in DMF (80ml) solution, add 3.038g of HBTU (8.0mmol) and DIEA (2ml) under ice cooling to activate After 10 minutes, it was added to a solid-phase reaction column and reacted at room temperature for 2 hours. Washed with DMF (100ml) 6 times, sucked dry and directly used in the next reaction.

[0065] Reaction bottle 2: use Rink Amide AM Resin 4.010g with a substitution degree of 0.997mmol / g as raw material, and use the same method as above to react in parallel.

[0066]Step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com