Recombinant yeast strain producing nervonic acid and its application

A yeast strain and yeast technology, applied in the field of engineered recombinant yeast strains, can solve the problems of wild strains being unable to synthesize nervonic acid, difficult to meet industrial needs, and shortages, and achieve good industrial application prospects and the effect of increased production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

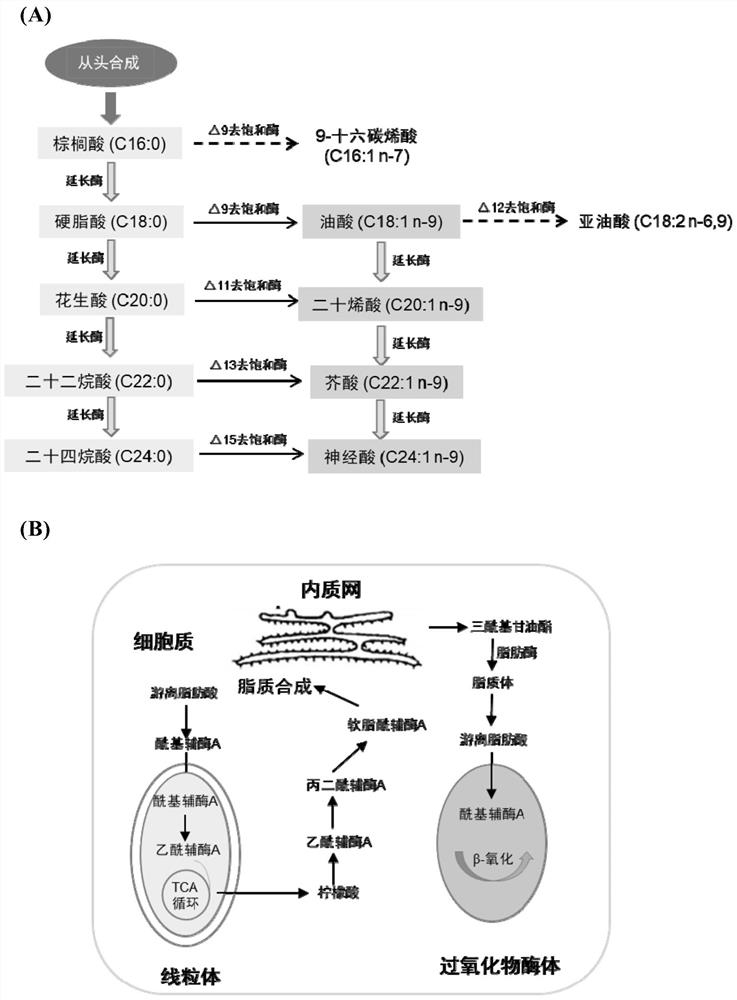

Method used

Image

Examples

Embodiment 1

[0127] Embodiment 1, plasmid construction

[0128] 1.1 Cloning of genetic elements

[0129] 1) Acquisition of genes DGAT1, SCD, PLA2-1, PLA2-2, PLA2-3, PLA2-4, PLA2-5, PLA2-6, ylGSR and ylGPO:

[0130] Yarrowia lipolytica strain (strain number polg, purchased from Yeastern Biotech Company, Taiwan) in YPD medium (YPD medium composition is glucose 20g / L, peptone 20g / L, yeast extract 10g / L)) After culturing, high-purity total genomic DNA was extracted by the CTAB (hexadecyltrimethylammonium bromide, hexadecyltrimethylammonium bromide) method. Add appropriate amount of bacteria into liquid nitrogen to freeze, grind into powder, add appropriate amount of 2×CTAB extraction buffer (100mmol / L Tris-HCl, pH8.0, 20mmol / L EDTA, 1.4mol / L NaCl, 2% (w / v )CTAB, 40mmol / L mercaptoethanol), at 65°C for 10 minutes, with intermittent shaking. Then add an equal volume of chloroform / isoamyl alcohol, gently invert the centrifuge tube to mix, centrifuge at 12,000 rpm for 10 min at room temperature,...

Embodiment 2

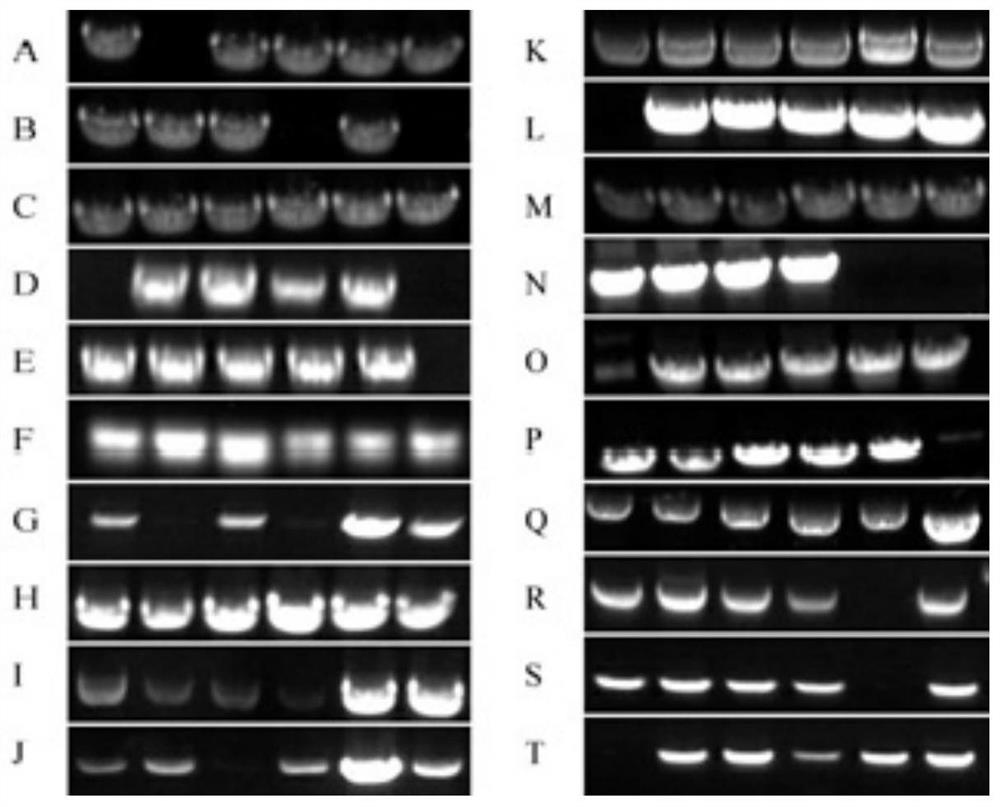

[0158] Embodiment 2, the construction of Yarrowia lipolytica engineering bacteria

[0159] 2.1 Obtaining the expression cassette

[0160] Plasmids pDS, pAB, pCgKCS, and pCgKCS recorded in Table 1 were digested with NotI endonuclease (purchased from Thermo Fisher Scientific) ER pCgKCS PTS , pCgKCS MTS , pC ER C MTS , pMCSD, pCB, pPLA2-1, pPLA2-2, pPLA2-3, pPLA2-4, pPLA2-5, pPLA2-6, pylGSR, pylGPO, prELO2, pCpLCE, pgELOVL6, pMaKCS, pD9DMB, pCeFAT6, pMaOLE2, pAtADS1, pAtADS2 , pEcAldH, pScZwf and pΔpex10.

[0161] The specific digestion system is: 10×FD Green Buffer, 2ul; NotI, 1ul; plasmid, 2 O make up to 20ul. The digested product was purified and recovered using Cycle Pure Kit (purchased from OMEGA bio-tek). The recovery steps were as follows: add 4-5 times the volume of buffer CP to the digested product; transfer to a DNA adsorption column after mixing, and centrifuge at 13,000g at room temperature for 1 Discard the filtrate and add 700 μL DNA washing buffer, centrifu...

Embodiment 3

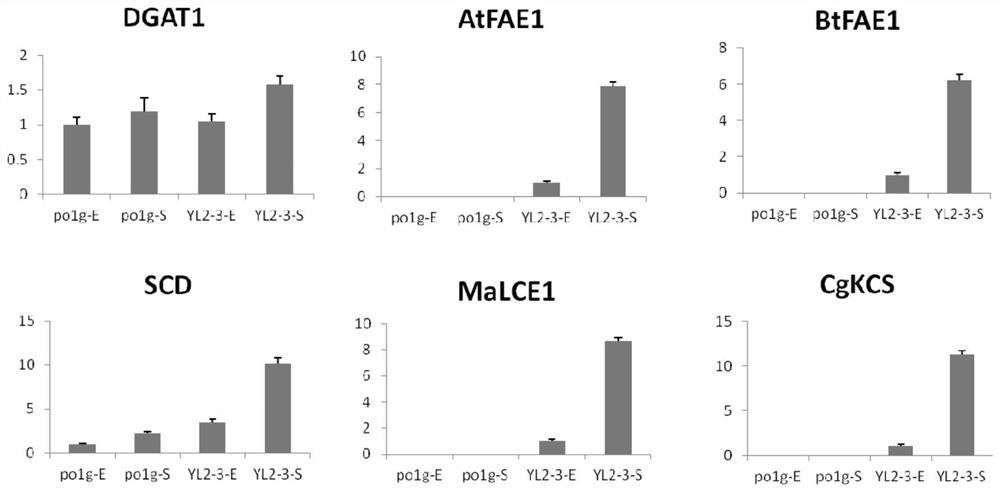

[0193] Embodiment 3, bacterial strain culture produces nervonic acid

[0194] 3.1 Strain shake flask culture and induction regulation

[0195] a. Activate the strains po1g and YL2-3 on the YPD solid plate, and culture them at 28°C for 1 day. Pick single colonies and inoculate them into 250ml shake flasks filled with 50ml YPD medium respectively, and cultivate them at 28°C for 1 day as the seed culture solution. Inoculate the seed culture solution into 250ml shake flasks containing 50ml YNB medium respectively to make the initial OD 600 0.2, cultured at 28°C for 6 days, ready to use.

[0196] Among them, the composition of YNB medium is 1.7g / L of YNB, 80g / L of glucose, 1.5g / L of yeast extract, 20mg / L of uracil, and 100mg / L of leucine.

[0197] b. The seed culture solution cultivated by the above method was inoculated into 250ml shake flasks containing 50ml induction medium respectively to make the initial OD 600 0.2, cultured at 28°C for 6 days, ready to use.

[0198] Wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com