A polymer monolithic column for on-line enrichment and purification of ursolic acid and a method for on-line enrichment and purification of ursolic acid

A technology of ursolic acid and polymer, which is applied in the field of preparation of separation materials, can solve the problems of large amount of solvent, long sample pretreatment time, small specific surface area, etc., and achieves shortened pretreatment time, good purification effect and simple preparation method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

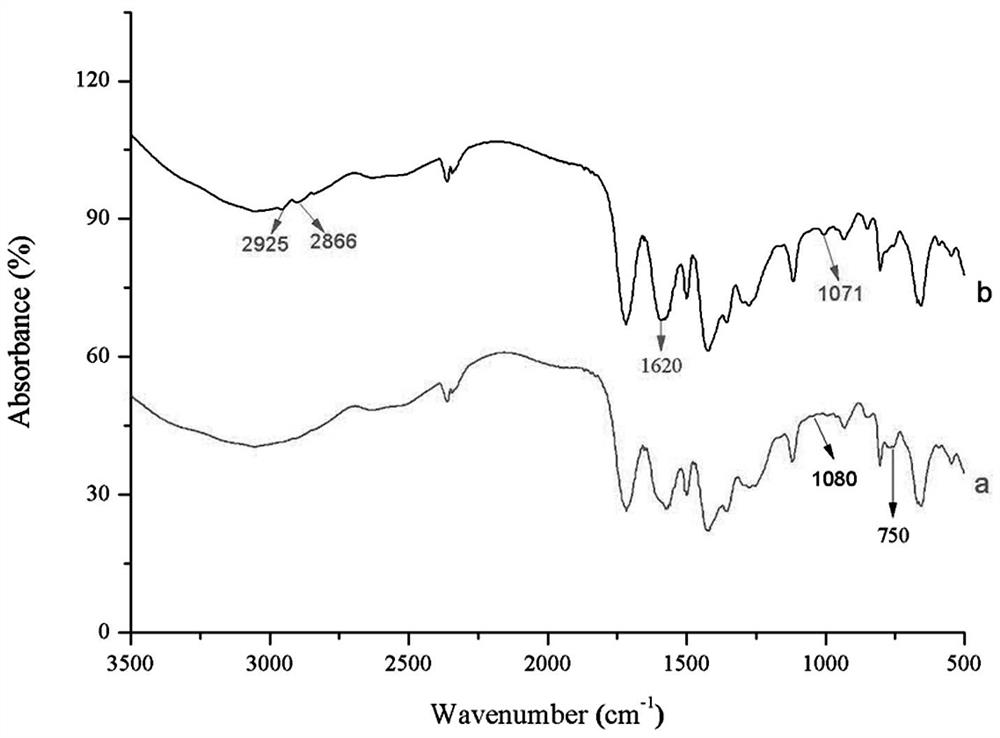

[0049] 4.3g pyromellitic acid and 2.3g ZrCl 4 Dissolve in ultrapure water at room temperature, reflux for 24 hours, wash the obtained white jelly, dissolve in ultrapure water and continue to reflux for 16 hours, centrifuge, wash, and dry the obtained solid to obtain a carboxyl-containing MOFs material. Disperse 1 mol of MOFs material with carboxyl groups and 1 mol of KH-570 in toluene and reflux for 8 hours to obtain derivatized MOFs material with carbon-carbon double bond, that is, functionalized MOFs material.

[0050] Precisely weigh 0.003g of benzoyl peroxide, 0.05g of N-isopropylacrylamide, and 0.002g of derivatized MOFs with carbon-carbon double bonds into a centrifuge tube, and immediately add 0.8mL of n-propanol, 0.8mL Polyethylene glycol 400 and 0.35mL ethylene glycol dimethacrylate, vortex and ultrasonic for 1h to disperse until the mixture is uniform, add N,N-dimethylaniline, mix quickly, put into a stainless steel column, After reacting for 3.5 hours in a water ba...

Embodiment 2

[0054] Under the same conditions as in Example 1, put 0.003g of benzoyl peroxide into a centrifuge tube, add 0.05g of N-isopropylacrylamide, 0.8mL of n-propanol, 0.8mL of polyethylene glycol 400 and 0.35mL of ethyl alcohol Diol dimethacrylate, vortex and ultrasonic for 1h to disperse until the mixture is uniform, add N,N-dimethylaniline, mix quickly, put it into a stainless steel column, and react in a water bath at 30°C for 3.5h. That is, a polymer monolithic column without MOFs material is obtained.

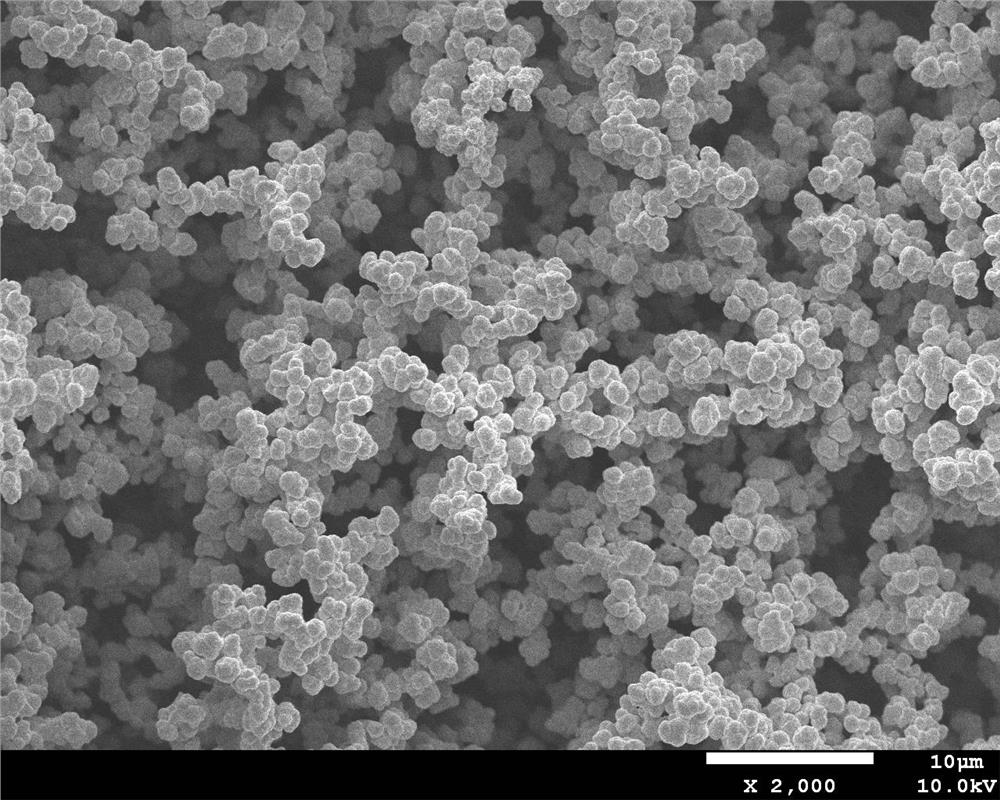

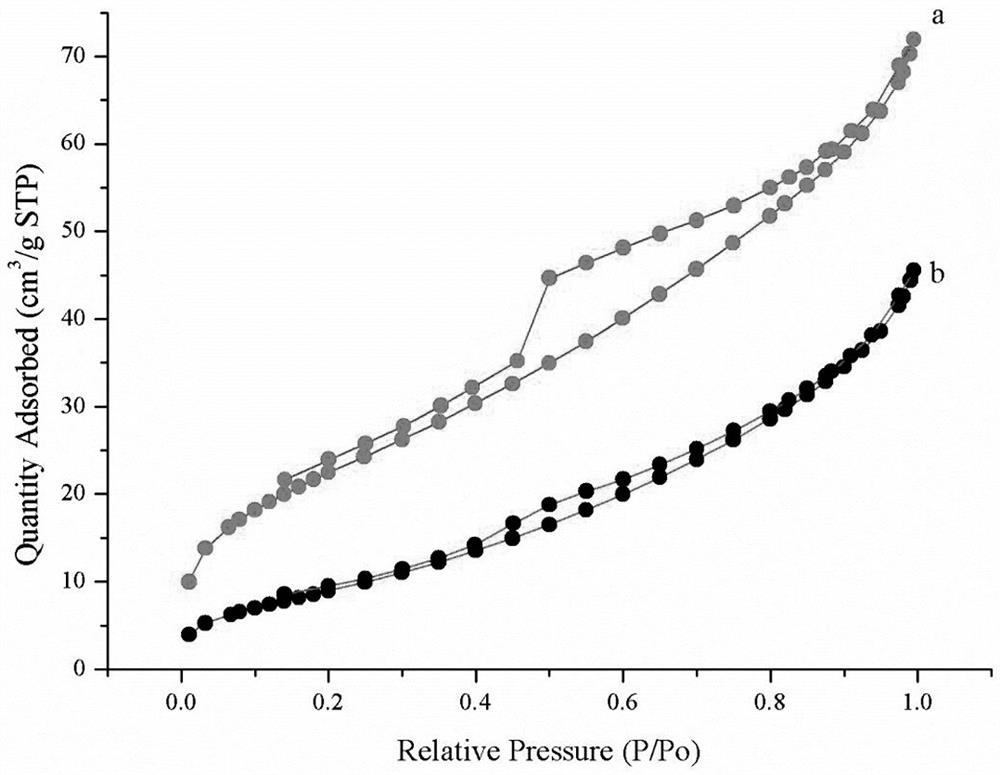

[0055] The microscopic morphology of the monolithic column prepared above was observed with a scanning electron microscope, and the obtained results are as follows: Figure 4 . The nitrogen adsorption-desorption isotherm of the monolithic column was measured with a specific surface area measuring instrument as image 3 As shown in the curve b, its specific surface area is 35.0921m 2 / g.

Embodiment 3

[0057] Under the same conditions as in Example 1, put 0.003g of benzoyl peroxide and 0.002g of derivatized MOFs with carbon-carbon double bonds into a centrifuge tube, add 0.05g of N-isopropylacrylamide, 0.25mL of ethylene diacetate Alcohol dimethacrylate, 0.8mL n-propanol, 0.8mL polyethylene glycol 400, vortex, ultrasonic 1h to disperse, until the mixture is uniform, add N,N-dimethylaniline, mix quickly, put into In the stainless steel column, after 3.5 hours of constant temperature reaction in a water bath at 30°C, the polymer monolithic column was obtained. The microscopic morphology of the monolithic column prepared above was observed with a scanning electron microscope, and the obtained results are as follows: Figure 5 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com