Plugging material and plugging method for large leakage casing damage section of oil-water well

A plugging material and technology for oil-water wells, applied in sealing/isolation, chemical instruments and methods, earthwork drilling and production, etc., can solve the lack of effective measures for plugging of casing damage sections with large leakage and cannot meet the plugging operations of old wells, Insufficient pressure resistance and other problems, to achieve the effect of improving plugging efficiency, increasing temperature resistance, and high success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A plugging material for a large loss casing section of an oil-water well, comprising a gel system and a resin system, the volume ratio of the gel system and the resin system is (4-8):(1-2).

[0051] The method for plugging the casing damage section of the oil-water well with large leakage includes the following operation process:

[0052] Step 1. Confirm the integrity of the upper wellbore in the casing damage section;

[0053] Step 2, setting up the drillable bridge plug at the lower part of the leakage casing damage section to establish an artificial platform;

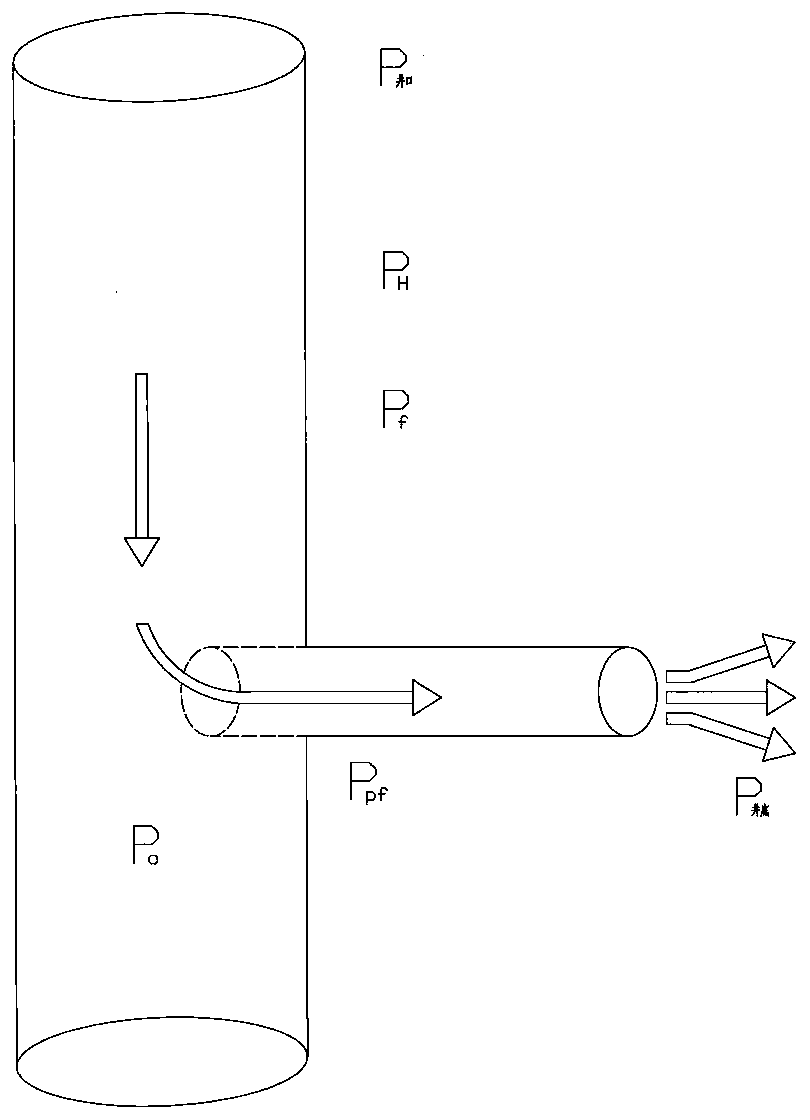

[0054] Step 3: Test the water absorption of the lost casing section, and run a bottomhole pressure gauge at the lower end of the test suction string to test the bottomhole pressure P of the lost casing section under different displacements 0 ;

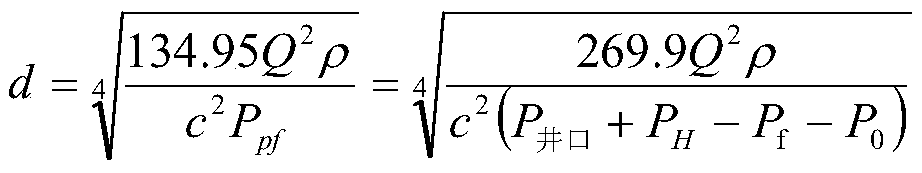

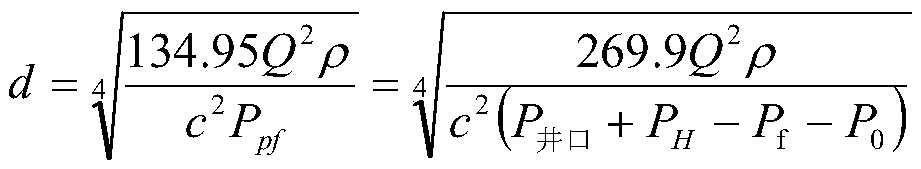

[0055] Step 4, according to the bottom hole pressure P obtained in step 3 0 , and use the Bernoulli equation to calculate the aperture size of the leakage casing se...

Embodiment 2

[0063] On the basis of Example 1, further, the gel system consists of the following raw materials in parts by weight: 100 parts of water, 0.35-0.45 parts of gel thickener, 0.3-0.5 parts of cross-linking agent, 5-8 parts of solid phase composition.

[0064] The gel thickener is polyacrylamide or polyacrylonitrile ammonium salt with a molecular weight of 3-4 million;

[0065] The crosslinking agent is one of zirconium lactate, zirconium hydroxide and zirconium silicate.

[0066] The solid phase composition is formed by mixing quartz sand: fiber: walnut shell in a mass ratio of 1: (1-2.5): (1-2.8).

[0067] The specific preparation method of the gel system is as follows: first, add the thickening agent of the formulation amount to 100 parts of water, stir for 10 to 20 minutes at a speed greater than 2000 rpm, and then let stand for 10 to 30 minutes until the viscosity of the system reaches After 70-120mPa·s, add the formulated amount of solid-phase composition, stir for 10-30 m...

Embodiment 3

[0069] On the basis of Example 1, further, the resin system includes the following raw materials in parts by weight:

[0070] Glycerol epoxy resin 100 parts

[0071] Resorcinol (curing agent) 8-10 parts

[0072] Aminophenolic resin 22.5-50 parts

[0073] Dioctyl phthalate (toughening agent) 12-15 parts

[0074] 1-3 parts of anilinomethyltrimethoxysilane (coupling agent);

[0075] Wherein, the epoxy value of the glycerol epoxy resin is 0.38-0.45.

[0076] The preparation method of described aminophenol-formaldehyde resin is: in the there-necked flask that thermometer, agitator and reflux condenser are housed, add phenol and mass concentration be 37% formaldehyde solution in the ratio of volume ratio 1:(1~1.8), then Based on the total volume (300-400ml) of the phenol and the formaldehyde solution, add ammonia water with a mass-volume ratio of 6-8%, stir and heat up to start reflux and react for 25-45min after the calculation time, and then the reaction time is 0.08-0.09MPa ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Dimension diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com