A kind of negative electrode material of lithium-ion power battery and preparation method thereof

A power battery and negative electrode material technology, applied in the direction of battery electrodes, negative electrodes, secondary batteries, etc., can solve the problems of low conductivity, weak battery life, poor safety, etc., and achieve improved electrochemical performance, improved electrical conductivity, The effect of small contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

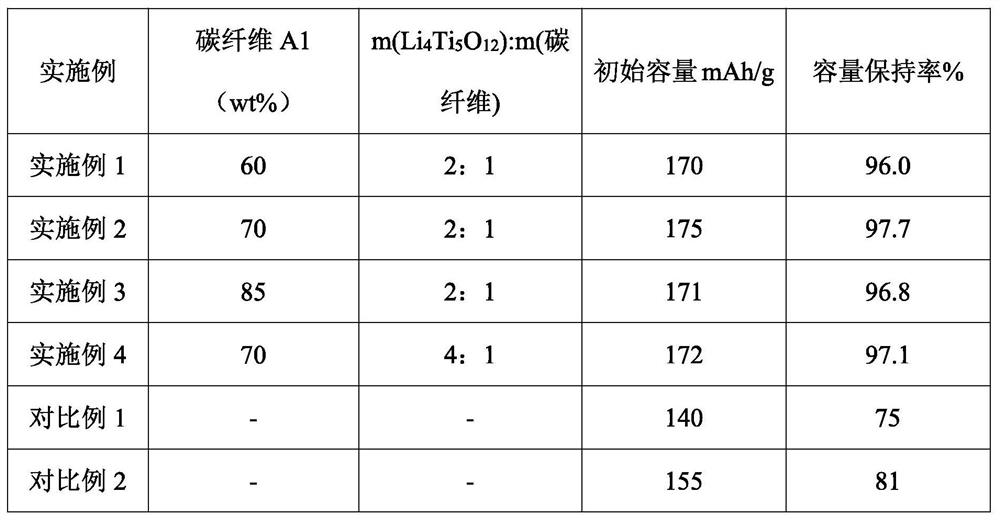

Embodiment 1

[0030] It is weighed 2G containing two different fiber diameter distribution of carbon fibers, including the fiber diameter distribution of 90%, and the diameter range of 5-30 nm range of carbon fibers A1 and the fiber diameter distributed in 90%, the diameter ranges from 50- The carbon fiber A2 of the 90 nm range is compared to 60% of the total mass of carbon fibers A1, which disperses the carbon fibers weighed above to 6 m, at 80 ° C, heat reflows for 12 h, then centrifugally, deionized After the water was rinsed 5-6 times, the ultrasonic dispersed into ethanol to obtain a dispersion of negative charge carbon fibers.

[0031] 62 g of titanate titanate was weeded to the above carbon fiber dispersion, and the reaction was stirred at 70 ° C for 8 h, and the emulsion was obtained, and then placed at a vacuum drying tank at 100 ° C for one day and night to give titanium dioxide / carbon fiber. It is weighed with 1 5.39 g of lithium carbonate, and it is mixed with the obtained titaniu...

Embodiment 2

[0034] It is weighed 2G containing two carbon fibers containing two different fiber diameter distributions, including the fiber diameter distribution of 90% or more, the diameter range of 5-30 nm range of carbon fibers A1 and the fiber diameter distribution in a diameter range of 50-90 nm The range of carbon fiber A2, wherein the ratio is 70% of the total mass of carbon fiber A1, which dispersed above the carbon fibers above 6 m, and heats refluxed at 80 ° C, then centrifugally, dispelled with deionized water. After washing 5-6 times, the ultrasonic dispersed into ethanol to obtain a dispersion of negative charge carbon fibers.

[0035] 62 g of titanate titanate was weeded to the above carbon fiber dispersion, and the reaction was stirred at 70 ° C for 8 h, and the emulsion was obtained, and then placed at a vacuum drying tank at 100 ° C for one day and night to give titanium dioxide / carbon fiber. It is weighed with 1 5.39 g of lithium carbonate, and it is mixed with the obtaine...

Embodiment 3

[0038] It is weighed 2G containing two carbon fibers containing two different fiber diameter distributions, including the fiber diameter distribution of 90% or more, the diameter range of 5-30 nm range of carbon fibers A1 and the fiber diameter distribution in a diameter range of 50-90 nm The range of carbon fiber A2, wherein the ratio is 85% of the total mass of carbon fiber A1, which dispersed above the carbon fibers above 6m nitric acid solution, at 80 ° C, refluxed at 80 ° C, then centrifugally, deionized water After washing 5-6 times, the ultrasonic dispersed into ethanol to obtain a dispersion of negative charge carbon fibers.

[0039] 62 g of titanate titanate was weeded to the above carbon fiber dispersion, and the reaction was stirred at 70 ° C for 8 h, and the emulsion was obtained, and then placed at a vacuum drying tank at 100 ° C for one day and night to give titanium dioxide / carbon fiber. It is weighed with 1 5.39 g of lithium carbonate, and it is mixed with the ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com