Preparation method of polypyrrole-coated three-dimensional graphene Co3O4 lithium battery negative electrode material

A technology of lithium tricobalt tetroxide and negative electrode materials, applied in the fields of materials science and electrochemistry, can solve the problems of MOF chemical stability and structural stability, electrical conductivity and cycle life need to be improved, irreversible capacity loss, etc., to achieve good cycle stability , Excellent electrochemical performance, excellent electrochemical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

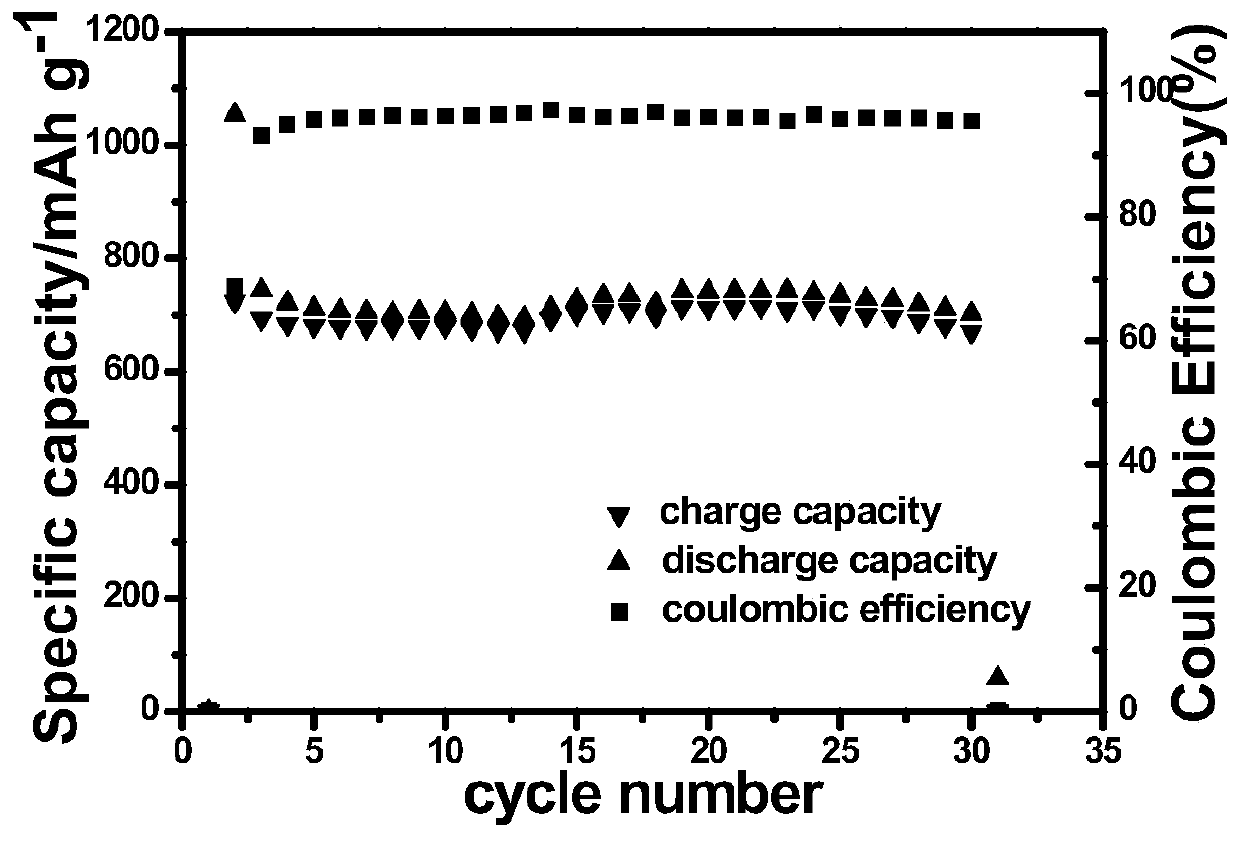

Embodiment 1

[0044] A method for preparing polypyrrole-coated three-dimensional graphene tricobalt tetroxide composite material, specifically comprising the following steps:

[0045] (1) 0.0415g potassium hexacyanocobaltate (K 3 [Co(CN) 6 ]) was added to 16.65mL graphene oxide solution (3mg / mL), dissolved in 100mL deionized water;

[0046] (2) Stir magnetically for 10 minutes, and mix the above solution evenly;

[0047] (3) Ultrasound for 5 minutes to form a uniformly mixed dispersion;

[0048] (4) 0.3424g cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) add in the above-mentioned solution, and stir 60min;

[0049] (5) Add 150mg ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) and 150 μL pyrrole, centrifuged after continuous stirring for 24 hours;

[0050] (6) The centrifuged product was freeze-dried overnight (24h);

[0051] (7) Put the obtained product into a tube furnace, raise the temperature to 350° C. at a heating rate of 10° C. / min, calcinate in an air atmosphere for 2 hours, and coo...

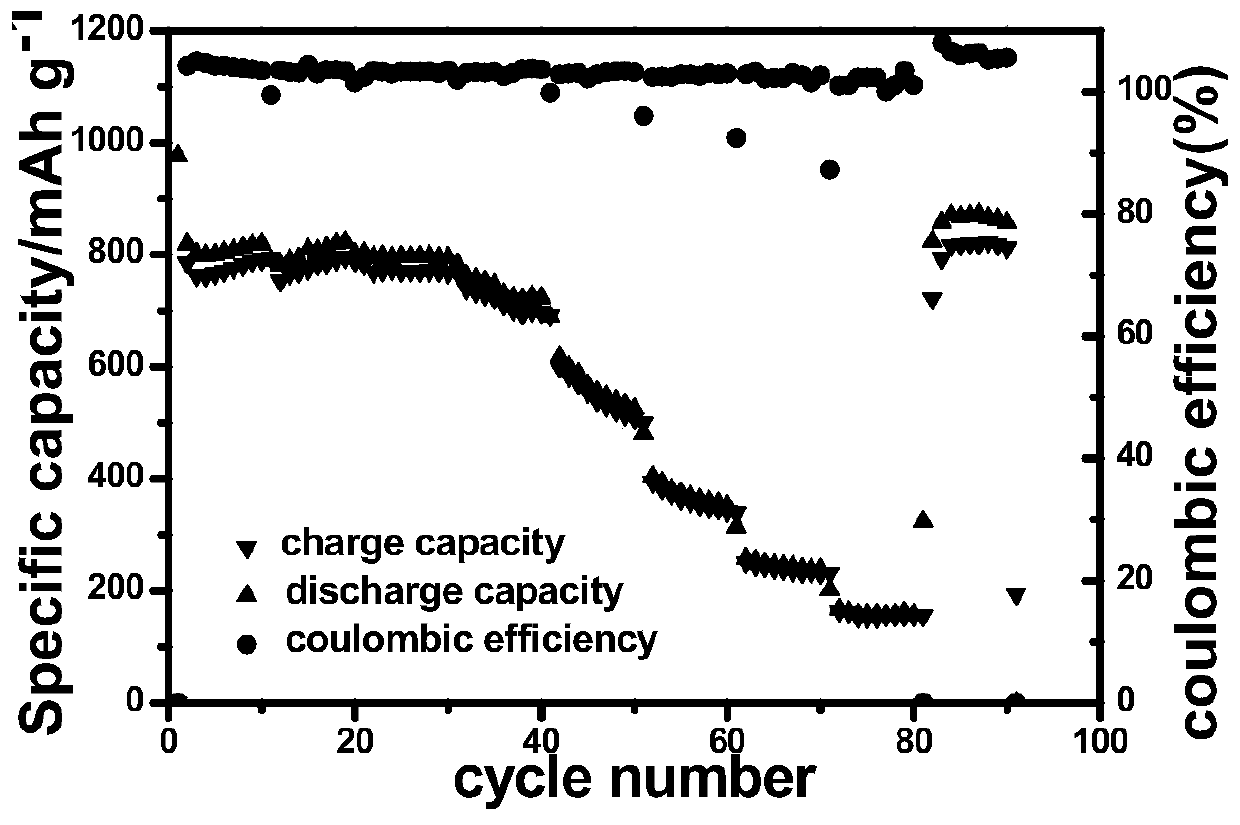

Embodiment 2

[0054] A method for preparing polypyrrole-coated three-dimensional graphene tricobalt tetroxide composite material, specifically comprising the following steps:

[0055] (1) Potassium hexacyanocobaltate (K 3 [Co(CN) 6 ]) added to the graphene oxide solution, graphene oxide (GO) and potassium hexacyanocobaltate (K 3 [Co(CN) 6 ]) in a mass ratio of 1:1, soluble in deionized water;

[0056] (2) Stir magnetically for 10 minutes, and mix the above solution evenly;

[0057] (3) Ultrasound for 5 minutes to form a uniformly mixed dispersion;

[0058] (4) Cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) add in the above solution, the addition is potassium hexacyanocobaltate (K 3 [Co(CN) 6 ]) 7.1 times of the mass, continue to stir for 60min;

[0059] (5) Ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) and pyrrole, ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) is added in an amount 3 times that of graphene oxide (GO) quality, and the added amount of pyrrole is ammonium persulfate ((NH ...

Embodiment 3

[0063] (1) Potassium hexacyanocobaltate (K 3 [Co(CN) 6 ]) added to the graphene oxide solution, graphene oxide (GO) and potassium hexacyanocobaltate (K 3 [Co(CN) 6 ]) with a mass ratio of 1.5:1, soluble in deionized water;

[0064] (2) Stir magnetically for 20 minutes, and mix the above solution evenly;

[0065] (3) Ultrasound for 10 minutes to form a uniformly mixed dispersion;

[0066] (4) Cobalt chloride hexahydrate (CoCl 2 ·6H 2 O) add in the above solution, the addition is potassium hexacyanocobaltate (K 3 [Co(CN) 6 ]) 7.2 times of the mass, continue to stir for 60min;

[0067] (5) Ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) and pyrrole, ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) is added in an amount 3 times that of graphene oxide (GO) quality, and the added amount of pyrrole is ammonium persulfate ((NH 4 ) 2 S 2 o 8 ) 3 times the mass, centrifuged after continuous stirring for 24 hours at room temperature;

[0068] (6) The centrifuged product was freeze-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Initial discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com