Polymer electrolyte membrane and solid-state battery

An electrolyte membrane and polymer technology, used in non-aqueous electrolyte batteries, electrolyte battery manufacturing, electrolytes, etc., can solve problems such as high price, no significant increase in electrical conductivity, and difficulty in improving compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

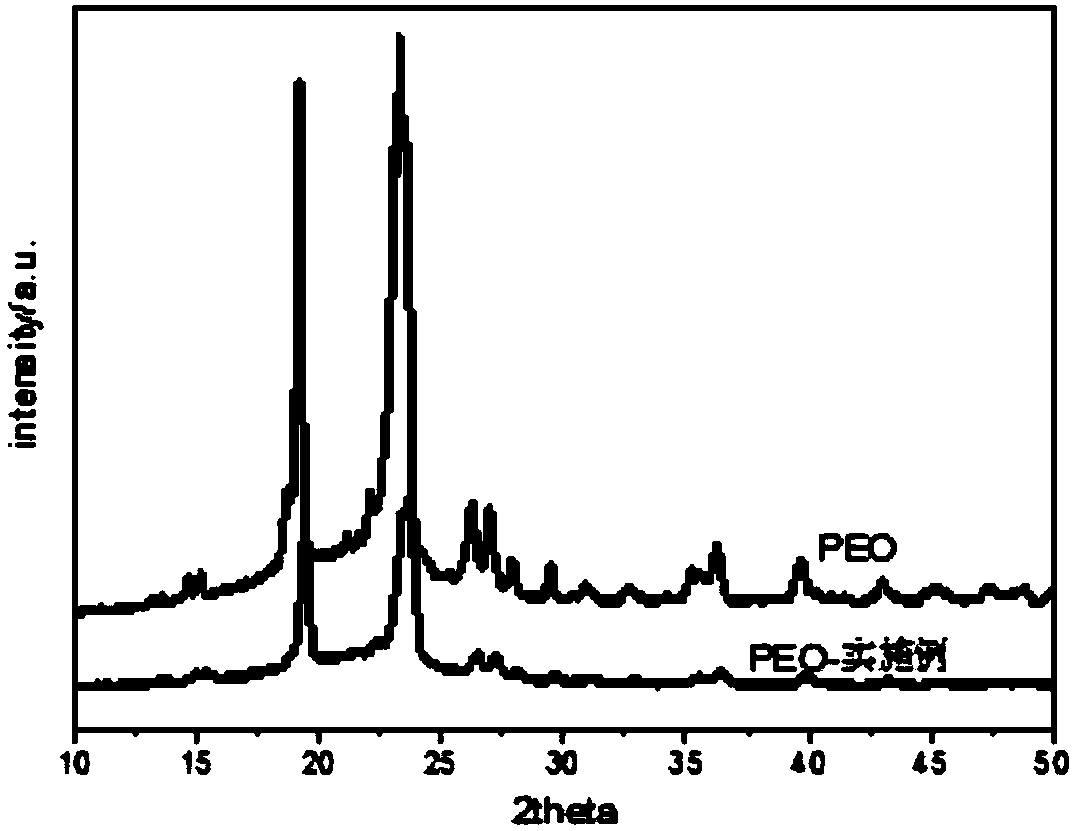

[0052] After diluting sodium dodecylbenzene sulfonate with water, first perform proton exchange with hydrochloric acid, and then add lithium hydroxide to prepare a neutral solution to obtain lithium dodecyl benzene sulfonate with a solid content of about 10%.

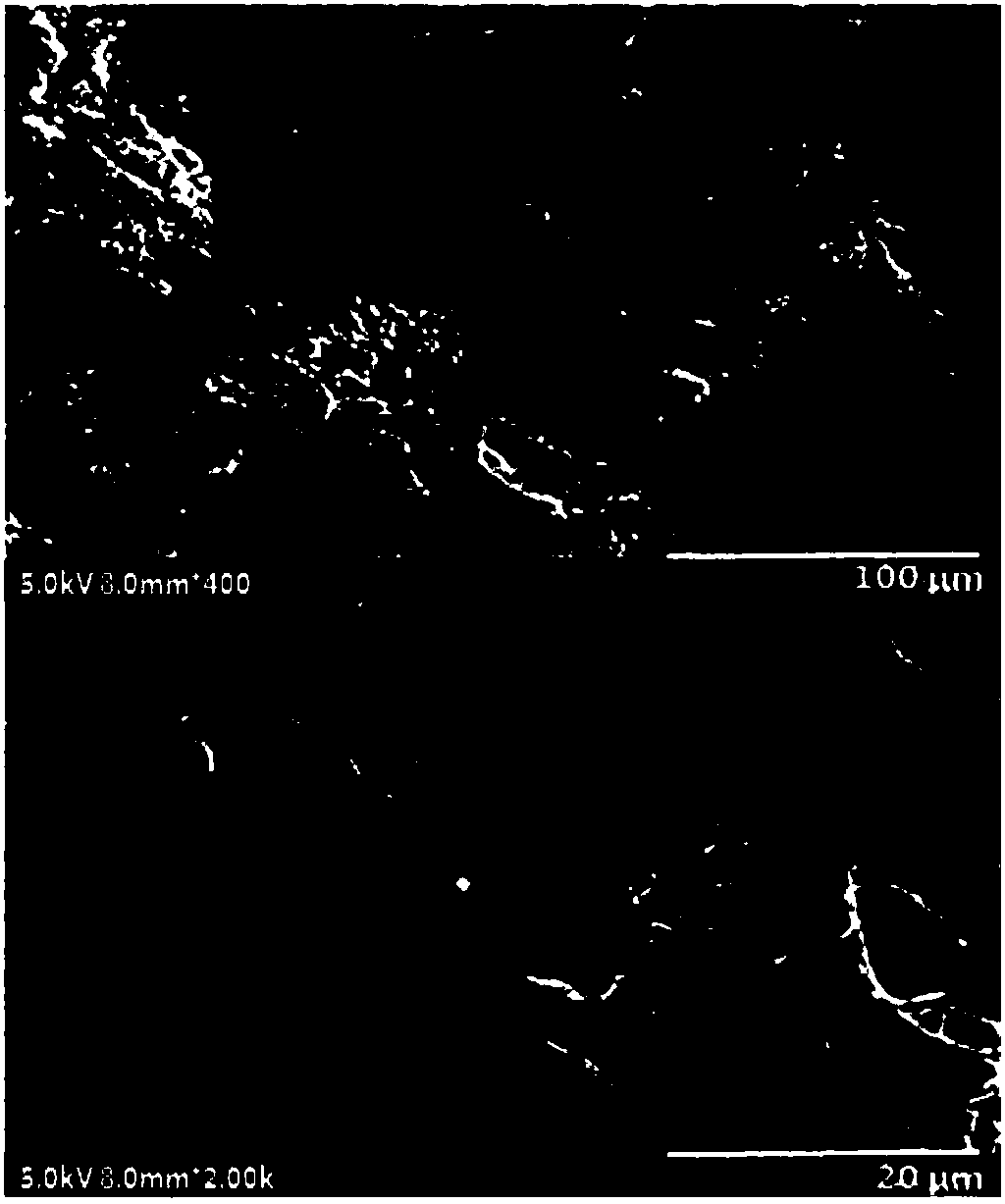

[0053] Mix PEO with a molecular weight of 400,000 g / mol and lithium dodecylbenzenesulfonate according to a mass ratio of 9:1, add deionized water, seal, heat and stir at 55°C for 24 hours to disperse uniformly to obtain a composite slurry.

[0054] Using the solution casting method, the composite slurry was placed in a polytetrafluoroethylene mold and dried at room temperature for 48 hours. The 14mm original sheet was dried in a vacuum oven at 55°C for 24h to obtain a polymer electrolyte membrane.

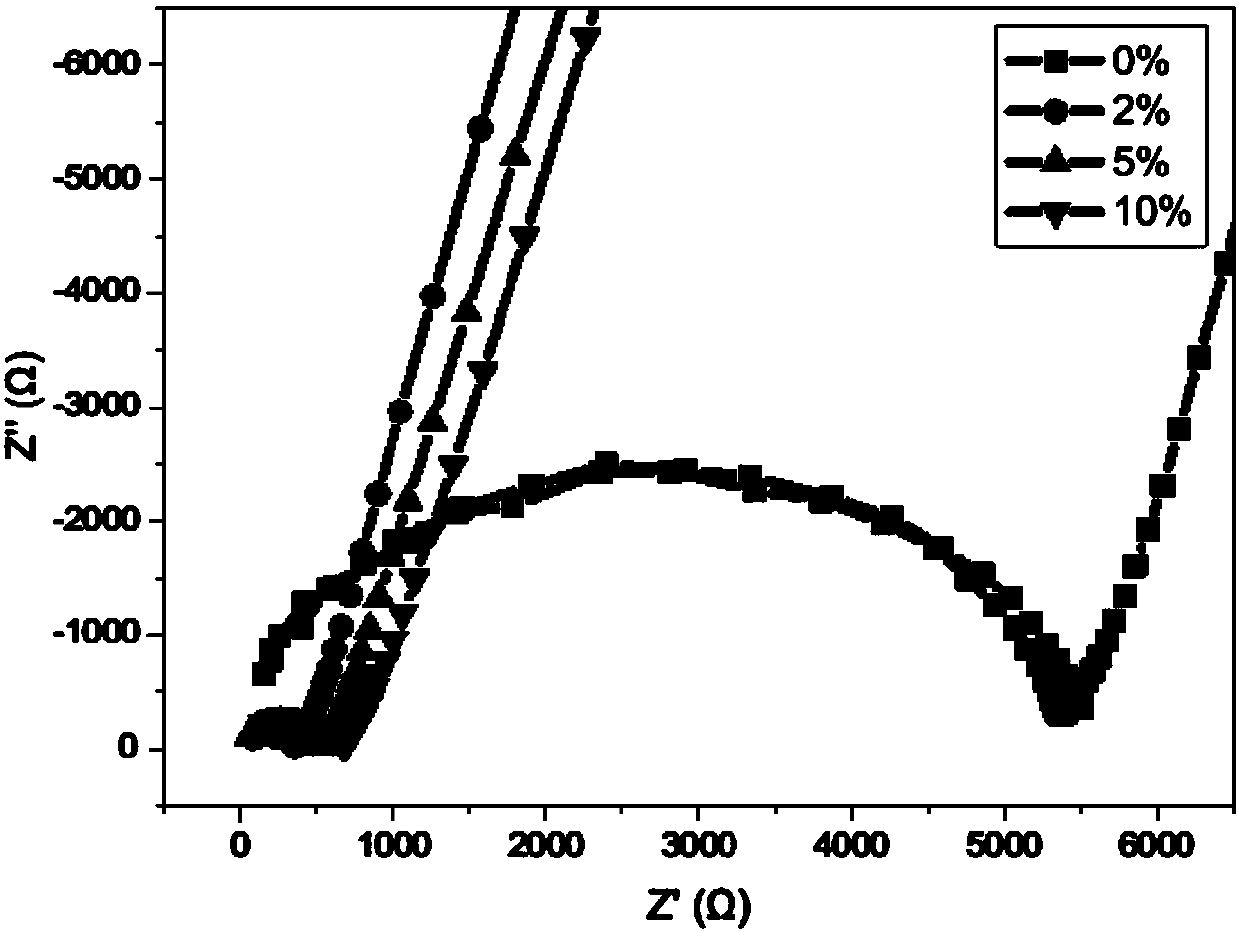

[0055] The CR2032 solid-state battery was assembled, with stainless steel electrodes on both sides, and the conductivity was tested. The results are shown in Table 1.

Embodiment 2

[0057] After diluting sodium dodecylbenzene sulfonate with water, first perform proton exchange with hydrochloric acid, and then add lithium hydroxide to prepare a neutral solution to obtain lithium dodecyl benzene sulfonate with a solid content of about 10%.

[0058] Mix PEO with a molecular weight of 200,000 g / mol and lithium dodecylbenzenesulfonate in a mass ratio of 49:1, add deionized water, seal, heat and stir at 55°C for 24 hours to disperse evenly; add LiTFSI lithium salt, and the oxygen-to-lithium ratio is 15: 1, to obtain a composite slurry.

[0059] Using the solution casting method, the composite slurry was placed in a polytetrafluoroethylene mold and dried at room temperature for 48 hours. The 14mm original sheet was dried in a vacuum oven at 55°C for 24h to obtain a polymer electrolyte membrane.

[0060] The CR2032 solid-state battery was assembled, with stainless steel electrodes on both sides, and the conductivity was tested. The results are shown in Table 1....

Embodiment 3

[0068] After diluting sodium dodecylbenzene sulfonate with water, first perform proton exchange with hydrochloric acid, and then add lithium hydroxide to prepare a neutral solution to obtain lithium dodecyl benzene sulfonate with a solid content of about 10%.

[0069] Mix PEO with a molecular weight of 300,000 g / mol and lithium dodecyl benzene sulfonate at a mass ratio of 19:1, add deionized water, seal, heat and stir at 55°C for 24 hours to disperse evenly; add LiTFSI lithium salt, and the oxygen-to-lithium ratio is 15: 1, to obtain a composite slurry.

[0070] Using the solution casting method, the composite slurry was placed in a polytetrafluoroethylene mold. After drying at room temperature for 48 hours, it was shot into an original sheet of φ14mm and dried in a vacuum oven at 55°C for 24 hours to obtain a polymer electrolyte membrane.

[0071] The CR2032 solid-state battery was assembled, with stainless steel electrodes on both sides, and the conductivity was tested. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com