Adhesion thermo-sensitive hydrogel of composite bioglass and preparation method and application of adhesion thermo-sensitive hydrogel

A temperature-sensitive hydrogel and bioglass technology, applied in the field of biomedical materials, can solve the problems of unfavorable wound healing, poor tissue adhesion and antibacterial performance, toxic and side effects, etc., and achieve improved biological activity, water solubility, good dispersibility, The effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] A preparation method of bioglass, comprising:

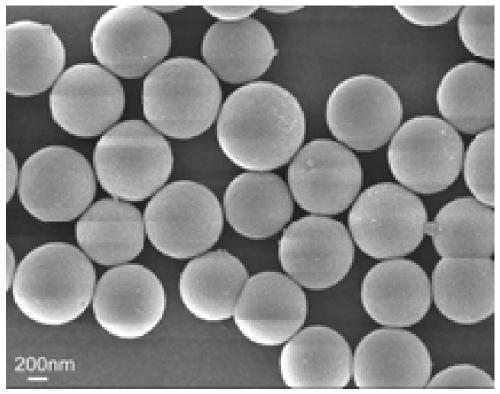

[0073] Medium SiO by Bioglass 2 :CaO:P 2 o 5 The molar ratio was 80:16:4 for the preparation. With 125mL of anhydrous ethanol / water mixed solution with a volume ratio of 16:5 as solvent, add 4g of dodecylamine, stir until completely dissolved, then add 16mL of ethyl orthosilicate and 1.22mL of triethyl phosphate dropwise, and finally Add 3.39g of calcium nitrate tetrahydrate and stir magnetically at 35°C for 3 hours to obtain bioglass sol. Collect the white precipitate, wash it alternately with anhydrous ethanol and deionized water for 3 times, and dry it in vacuum to obtain a white lump; then transfer the white lump to a crucible for high-temperature calcination, and maintain the heating rate at 2°C / min to 650 °C for 3 hours; after high-temperature calcination, natural cooling to obtain a powdery white powder, which is rice bioactive glass.

[0074] Characterize with the bioglass prepared by the above-mentioned embod...

Embodiment 2

[0077] A method for preparing an adhesive thermosensitive hydrogel of composite bioglass, comprising the following steps:

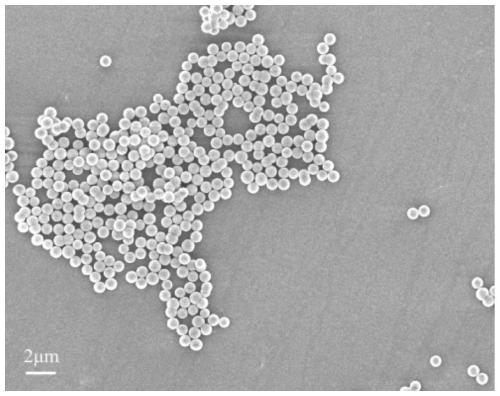

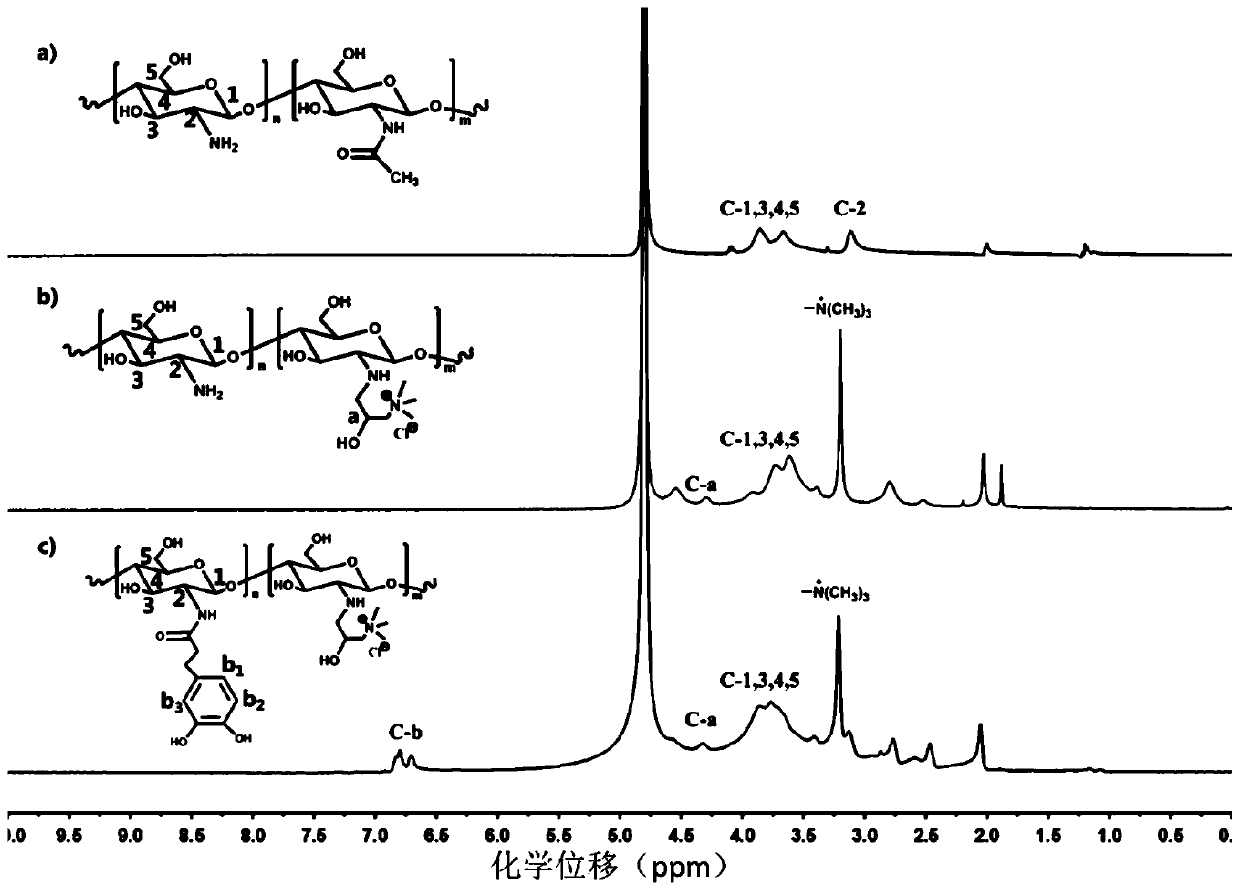

[0078] At normal temperature, chitosan (CS) (purchased from Sigma-Aldrich, product number: 448877) was dissolved in the acetic acid solution of 87.5mmol / L, magnetically stirred at room temperature for 12h to obtain 1-1.5wt% CS solution, and then Add 1.16 mL of an aqueous solution of 2,3-epoxypropyltrimethylammonium chloride (GMTAC) (9.25-9.30 mmol / L) within 1 h, wherein the molar weight of GMTAC is 1.5-1.6 times that of the amino group on chitosan. The reaction was stirred at 55° C. for 18 hours, and after the reaction was completed, quaternized chitosan (QCS) was obtained after dialysis and freeze-drying. After testing, the yield of the QCS is greater than 80%, and its grafting rate can reach 45-47% according to NMR;

[0079] Under normal temperature conditions, stir and dissolve the prepared QCS in an aqueous solution to obtain an aqueous solution of a...

Embodiment 3

[0084] A method for preparing an adhesive thermosensitive hydrogel of composite bioglass, comprising the following steps:

[0085] At room temperature, dissolve chitosan in 87.5 mmol / L acetic acid solution, stir magnetically at room temperature for 12 hours to obtain a CS solution with a mass concentration of about 1.5%, and then slowly add 1.16 mL of 2,3-epoxypropyltrimethyl chloride An aqueous solution of ammonium chloride (GMTAC) (9.25-9.30 mmol / L), wherein the molar weight of GMTAC is 1.5-1.6 times that of the amino group on chitosan. The reaction was stirred at 60°C for 20 hours, and after the reaction was completed, the quaternized chitosan (QCS) was obtained after dialysis and freeze-drying. After testing, the yield of the QCS is greater than 80%.

[0086] Under normal temperature conditions, stir and dissolve the prepared QCS in an aqueous solution to obtain a 0.08 g / mL aqueous solution of QCS, adjust its pH to 4.5 with 2M HCl solution, add dopamine hydrochloride, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com