Crystal modifier, medical flaky alpha-hemihydrate calcium sulfate and preparation method thereof

A technology of calcium sulfate hemihydrate and crystallizing agent, which is used in the preparation of sulfide, calcium/strontium/barium sulfate, organic chemistry, etc., can solve problems such as non-conformity, excessive particle size, etc., and achieves convenient operation and particle size. Small, low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

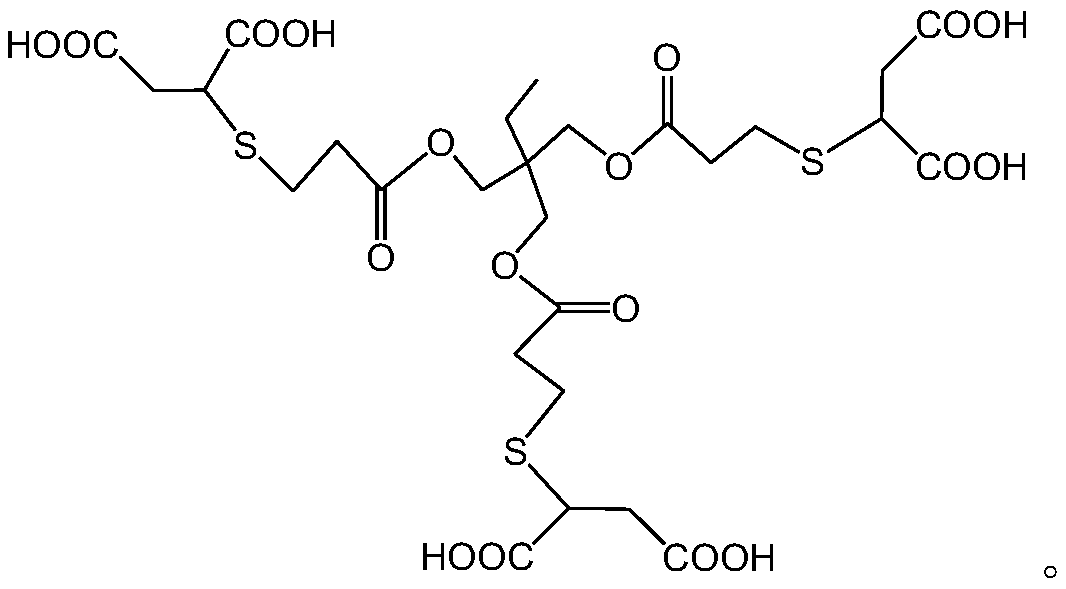

[0028] The preparation method of crystal transformation agent:

[0029] Add trihydroxymethylpropane tris(3-mercaptopropionate) (4.0g, 10.0mmol), maleic anhydride (2.94g, 30mmol) and potassium hydroxide 0.15g in 100ml solvent benzene, stir well, heat at 85 Reaction at ℃ for 7.5h. After the reaction, add 20ml of water, adjust the pH to weak acidity, cool and crystallize, suction filter, wash, and dry to obtain white solid trihydroxymethylpropane tris(3-mercaptopropionate)maleic acid.

[0030] Performance Characterization:

[0031] The product was characterized by infrared spectroscopy, IR (KBr) υ: 3267 (-COOH), 2874 (-CH 2 ), 1740(-C=O), 1211(C-O)cm -1 . It was verified that the obtained product was trimethylolpropane tris(3-mercaptopropionate) maleic acid.

Embodiment 2

[0033] The preparation method of medical flake α-calcium sulfate hemihydrate:

[0034] Prepare high-grade pure calcium nitrate solution (1.5mol / L) and potassium sulfate solution (1.5mol / L) respectively, and mix according to the molar mass ratio of calcium nitrate and potassium sulfate of 2.5:1. Then add 2% trihydroxymethylpropane tris(3-mercaptopropionate)maleic acid crystal conversion agent with the total mass of calcium nitrate and potassium sulfate, stir evenly, adjust pH to 5.5, and obtain white slurry. Put the configured slurry in the reactor, heat it, stir and reflux at 95°C for 3 hours, and fully complete the hydrothermal reaction to generate α-calcium sulfate hemihydrate. Suction filter the α-calcium sulfate hemihydrate slurry, wash twice with 95% ethanol, and dry in a constant temperature drying oven at 60°C for 2.0 hours to obtain medical grade flake α-calcium sulfate hemihydrate.

[0035] Performance Characterization:

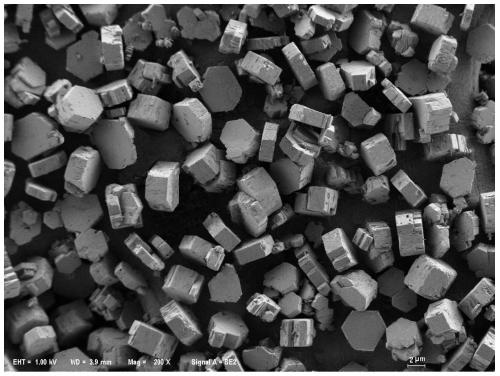

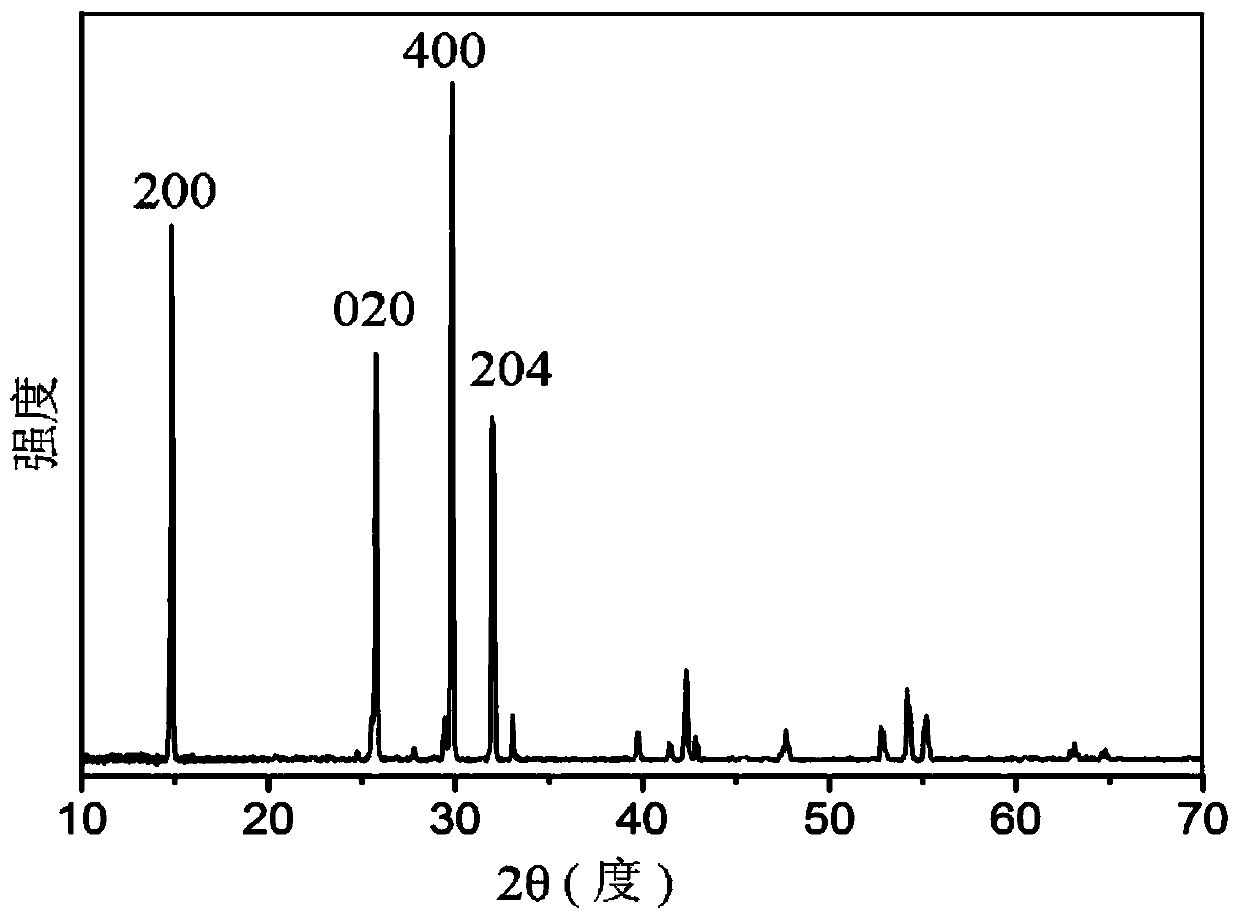

[0036] Such as figure 1 As shown, the α-cal...

Embodiment 3

[0038] Preparation:

[0039] Prepare high-grade pure calcium nitrate solution (1.5mol / L) and potassium sulfate solution (1.5mol / L) respectively, and mix them according to the molar mass ratio of calcium nitrate and potassium sulfate at a ratio of 3:1. Then add a trihydroxymethylpropane tris(3-mercaptopropionate)maleic acid crystal conversion agent with a total mass of 1.5% of calcium nitrate and potassium sulfate, stir evenly, and adjust the pH to 6.0 to obtain a white slurry. Put the configured slurry in the reactor, heat, stir and reflux at 98°C for 3 hours, fully complete the hydrothermal reaction to generate α-calcium sulfate hemihydrate. Suction filter the α-calcium sulfate hemihydrate slurry, wash twice with 95% ethanol, and dry in a constant temperature drying oven at 60°C for 2.0 hours to obtain medical grade flake α-calcium sulfate hemihydrate.

[0040] Performance Characterization:

[0041] The α-calcium sulfate hemihydrate crystals prepared in Example 3 are flaky,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com