Metal oxide alloy nanowire and preparation method thereof, and application of metal oxide alloy nanowire

A technology of alloy nano and oxide, applied in the direction of oxide/hydroxide preparation, nanotechnology, nano optics, etc., can solve the problem of high cost of copper indium gallium selenide nanowires, achieve oxygen vacancy concentration suppression, excellent electrical performance, The effect of simple growing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0162] A kind of preparation method of ultraviolet detector comprises the steps:

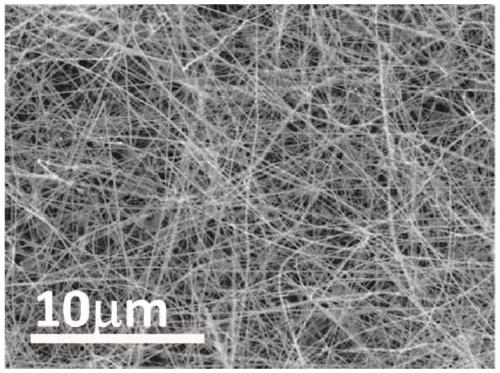

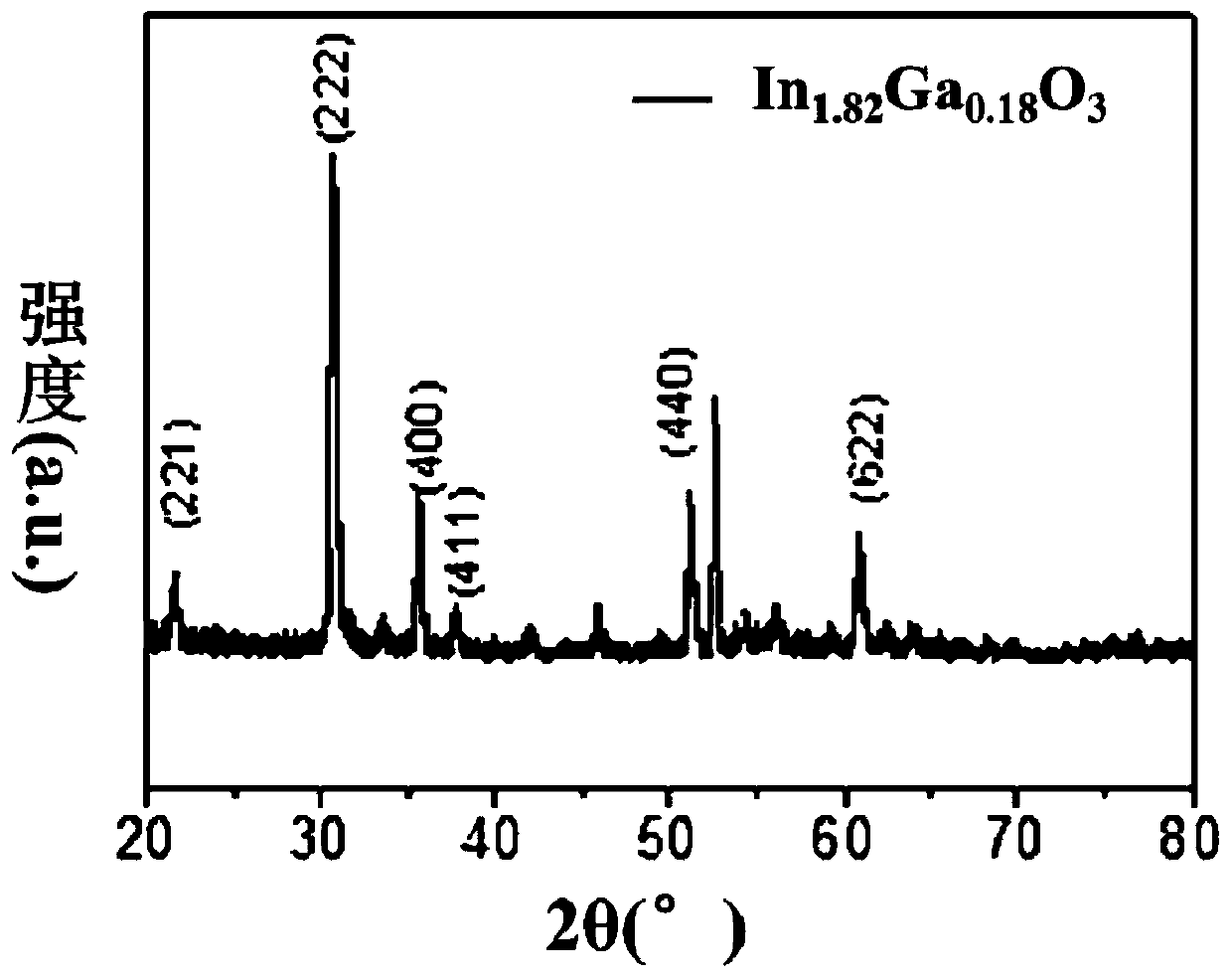

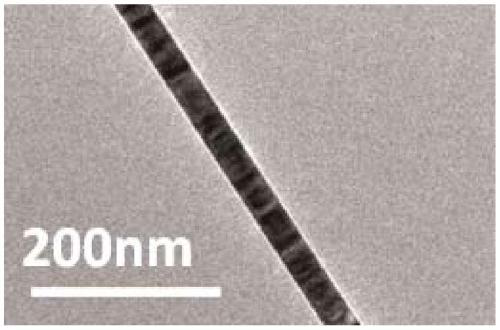

[0163] (1) The growth of metal oxide alloy nanowires comprises the following steps:

[0164] (a) According to the molar ratio of metal gallium (Ga, 99.99%) and metal indium (In, 99.99%) is 1:1, the ratio of the total mass of metal gallium and metal indium to graphite mass is 1:2, metal gallium , metal indium and graphite are blended and mixed to prepare mixed materials;

[0165] (b) Ultrasonic cleaning of the substrate for 30min and drying, the substrate is surface SiO 2 A p-type silicon wafer with a thickness of 50nm is deposited on the substrate by thermal evaporation Depositing a gold nanofilm at a rate of 100 to obtain a catalyst layer with a thickness of 1 nm;

[0166] (c) under a protective atmosphere with a gas flow rate of 100 sccm and a volume ratio of argon and oxygen of 9:1, the substrate containing the catalyst layer and the mixed material obtained in step (a) are placed in the c...

Embodiment 2

[0191] The difference from Example 1 is that the molar ratio of metal gallium and metal indium in step (a) is 1.2:1, its responsivity is 18% of that of Example 1, the response time is 0.117 seconds, and the recovery time is 0.119 seconds .

Embodiment 3

[0193] The difference from Example 1 is that the molar ratio of metal gallium and metal indium in step (a) is 1.5:1, its responsivity is 0.2% of that of Example 1, the response time is 0.067 seconds, and the recovery time is 0.158 seconds .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com