A kind of preparation method of lanthanum hexaboride whisker

A technology of lanthanum hexaboride and whiskers, which is applied in the field of preparation of lanthanum hexaboride whiskers, can solve the problems of excessively large specific surface area of aluminum flux, unfavorable growth of lanthanum hexaboride whiskers, and reduced production efficiency, and the like. Easy-to-achieve, easy-to-obtain, high-quality results for growing conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

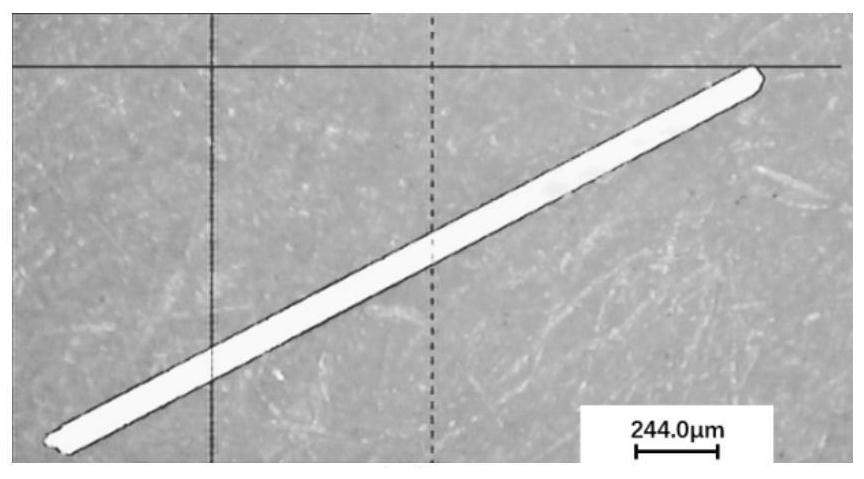

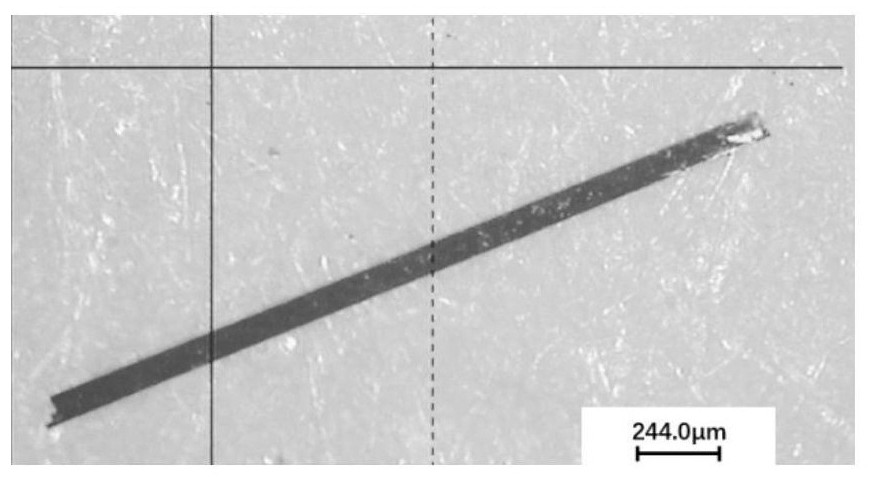

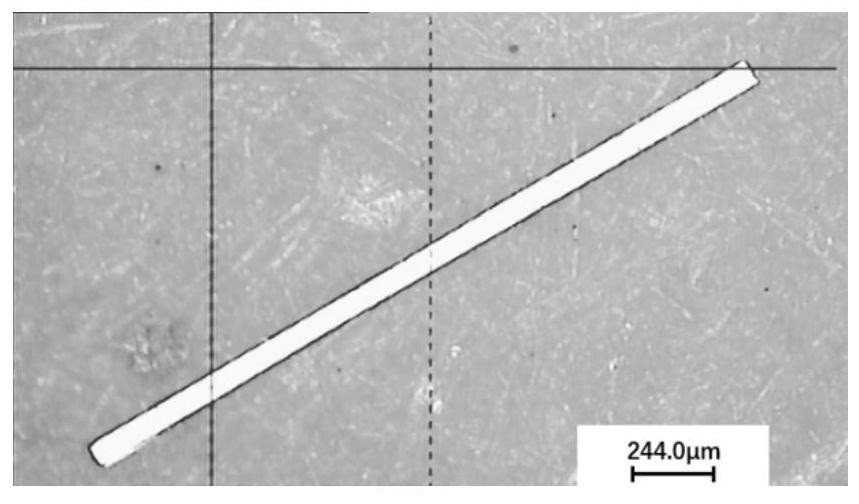

Image

Examples

Embodiment 1

[0029] In the glove box, first remove the black oxide film on the surface of the metal lanthanum rod to expose the silver metal lanthanum. Then file 2 g of metal lanthanum powder and mix it with 1 g of boron powder. Put the metal lanthanum powder and boron powder into a mortar and grind for 30 minutes, so that the metal lanthanum powder and boron powder are fully mixed. Add 20g of aluminum particles into the alumina crucible, then pour the evenly mixed ingredients into the crucible, shake gently so that the ingredients are filled into the gaps of the aluminum particles, and then add 7g of aluminum particles to cover the surface of the metal lanthanum powder and boron powder. Put the alumina crucible into the induction heating device, raise the temperature to 700°C in an environment with a vacuum degree of 3pa, and stop heating after the aluminum particles are fully melted. Then put the alumina crucible into the furnace for sintering, adjust the heating rate to 100°C / h, raise t...

Embodiment 2

[0032] In the glove box, first remove the black oxide film on the surface of the metal lanthanum rod to expose the silver metal lanthanum. Then file 3 g of metal lanthanum powder and mix it with 1.5 g of boron powder. Put the metal lanthanum powder and boron powder into a mortar and grind for 30 minutes, so that the metal lanthanum powder and boron powder are fully mixed. Put 14g of metal aluminum in the alumina crucible, then put it into the induction heating device, and heat it under the environment with a vacuum degree of 3pa. After the aluminum block melts, stop heating and take out the alumina crucible. Add 2.25g metal lanthanum powder and boron powder on the aluminum layer, and then add 14g aluminum on the metal lanthanum powder and boron powder, put it into an induction heating device and heat it under a vacuum degree of 3pa. Repeatedly, a material structure with three layers of aluminum sandwiched between two layers is obtained. Then put the crucible into the furnace ...

Embodiment 3

[0035]In the glove box, first remove the black oxide film on the surface of the metal lanthanum rod to expose the silver metal lanthanum. Then file 3 g of metal lanthanum powder and mix it with 1.5 g of boron powder. Put the metal lanthanum powder and boron powder into a mortar and grind for 30 minutes, so that the metal lanthanum powder and boron powder are fully mixed. Put 30g of metallic aluminum in an alumina crucible, then put it into an induction heating device, and heat it in an environment with a vacuum degree of 3pa. After the aluminum block melts, stop heating and take it out. After cooling, punch holes in the vertical direction of the aluminum block, fill the holes with metal lanthanum powder and boron powder, and cover the 10g aluminum block on the metal lanthanum powder and boron powder. Then, put the crucible into the furnace for sintering, adjust the heating rate to 100°C / h, raise the temperature to 1350°C and keep it for 12 hours, and the cooling rate is 100°C / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com