Multi-level structure calcite, preparation method and application thereof

A calcite and reaction technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of aminohydroxy compounds, etc., to achieve the effects of rich pores, good catalytic performance, and good structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] The present invention also provides a kind of preparation method of multi-level structure calcite, comprising the following steps:

[0044] a) urea and soluble organic calcium salt are mixed in a solvent, and the mixed system is subjected to reflux reaction under microwave irradiation to obtain a precipitate;

[0045] The number of carbon atoms of the soluble organic calcium salt is less than or equal to 3;

[0046] b) calcining the precipitate to obtain calcite with a hierarchical structure.

[0047] In the preparation method provided by the present invention, firstly, urea and soluble organic calcium salt are mixed in a solvent. Wherein, the number of carbon atoms of the soluble organic calcium salt is less than or equal to 3, preferably less than or equal to 2; the soluble organic calcium salt can be specifically selected from one or more of calcium formate, calcium acetate, calcium propionate and calcium lactate; the The solvent includes but is not limited to ethy...

Embodiment 1

[0064] Preparation of hierarchical calcite:

[0065] A certain amount of urea and calcium acetate were dissolved in 30 mL of ethylene glycol, the calcium ion concentration was 0.1 mol.L, and the urea / calcium ion molar ratio was 1:1; The illumination power was 400W, and the reaction time was 10min to form a white precipitate; after that, the precipitate was centrifuged, washed, and dried, and then calcined in a muffle furnace at 500°C for 3 hours to obtain multi-level calcite.

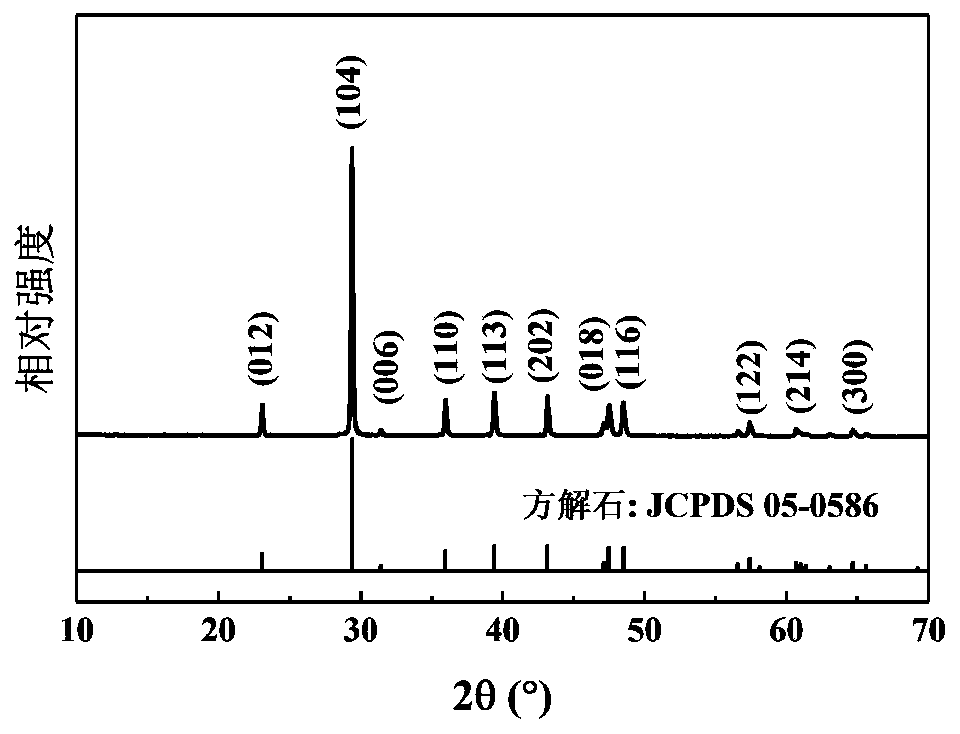

[0066] The multi-level structure calcite prepared in the present embodiment is detected by X-ray diffraction, and the results are as follows figure 1 shown, figure 1 is the X-ray diffraction spectrum provided in Example 1 of the present invention. pass figure 1 It can be seen that the product prepared in this example is a pure phase of calcite.

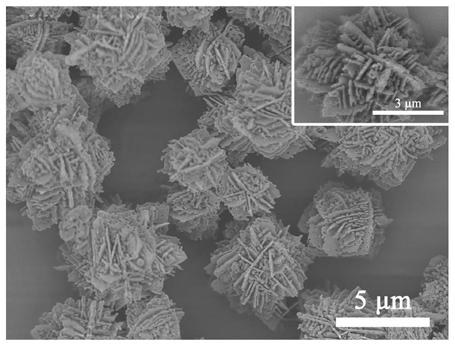

[0067] The multi-level structure calcite prepared in the present embodiment is observed by scanning electron microscope, and the results are as follows f...

Embodiment 2

[0072] Nano-silver adsorption recovery experiment

[0073] 1) Preparation of simulated nano-silver wastewater: under magnetic stirring (800 rpm), 5 mL of sodium borohydride (10 g / L) was added to 400 mL of a mixed solution of silver nitrate (0.25 mmol / L) and polyvinylpyrrolidone (0.5 g / L). L) solution, after 12 hours of reaction, the volume was adjusted to 500 mL to obtain. Among them, the concentration of nano-silver is 21.6 mg / L, which can be diluted to obtain nano-silver wastewater with different silver concentrations.

[0074] 2) Adsorption and recovery of nano-silver: Measure a series of 25 mL of simulated wastewater with a nano-silver concentration of 10.8 mg / L in a 50 mL beaker, and adjust the pH to 6.0, 7.0, 8.0, 9.0 and 10.0 with dilute nitric acid and sodium hydroxide solution, respectively. , under the condition of magnetic stirring (400rpm), add 5mg of the hierarchical structure calcite prepared in Example 1, separate the adsorbent by low-speed centrifugation (2100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com