Wine red glass, components for preparing wine red glass and preparation method

A wine red and glass technology, applied in the field of glass production, can solve the problems of high price of colorant, unstable performance of colorant, difficulty in color control, etc., achieve easy control of coloring effect and stability, good heat absorption and heat preservation and Invisibility function, effect of less volatilization loss of thermal decomposition heat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

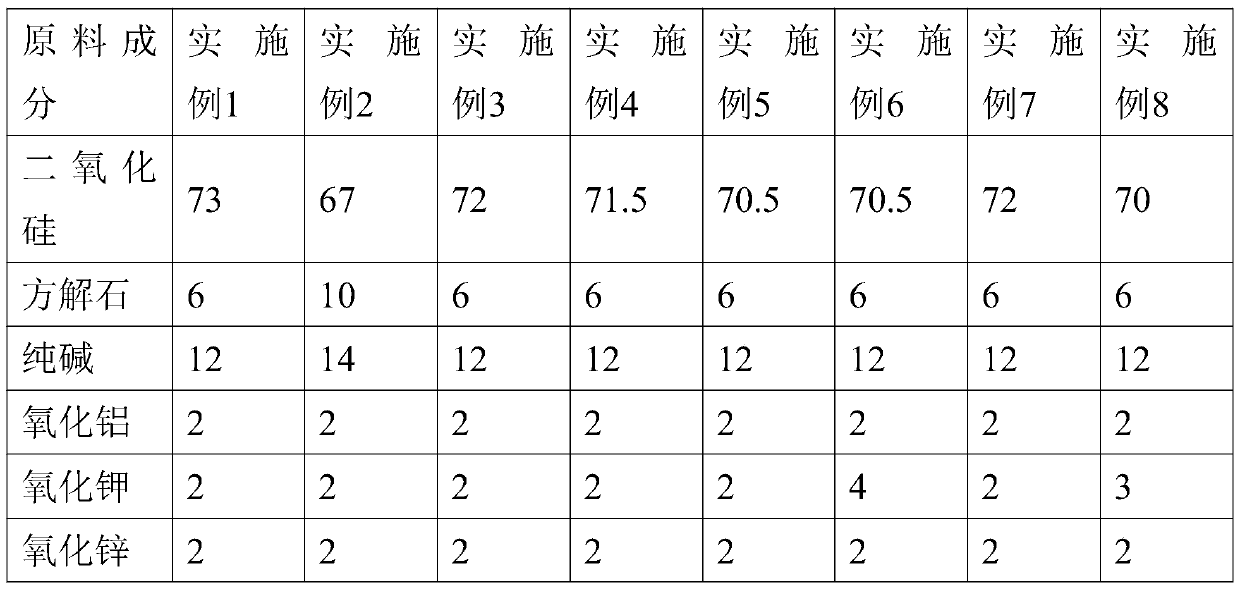

[0035] A high-quality wine red glass, including the following raw materials by weight:

[0036] Silica: 73 parts;

[0037] Calcite: 6 servings;

[0038] Soda ash: 12 parts;

[0039] Alumina: 2 parts;

[0040] Potassium oxide: 2 parts;

[0041] Zinc oxide: 2 parts;

[0042] Sodium borate hydrate; 2 parts;

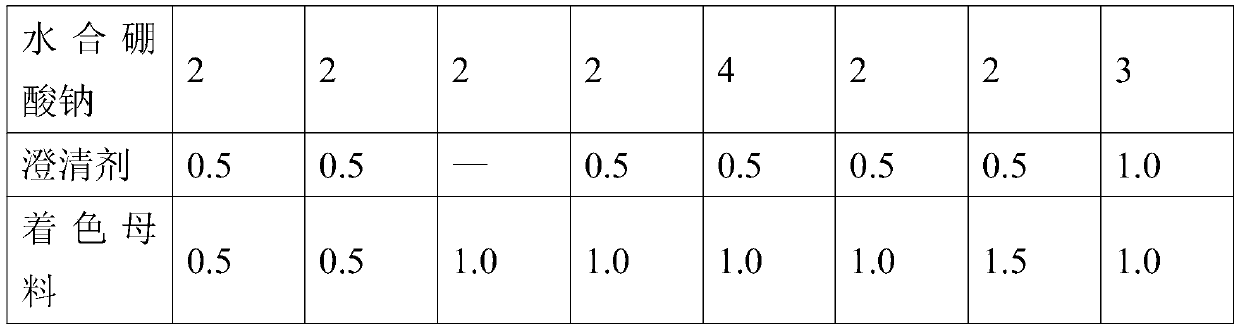

[0043] Clarifying agent: 0.5 part;

[0044] Coloring masterbatch: 0.5 part;

[0045] The preparation method of described coloring masterbatch is:

[0046] Titanium dioxide, white carbon black, manganese oxide, and water glass are mixed in a mass ratio of 7:3:40:50, melted by heating at 1100°C, quenched and cooled in water, dried and broken into 30 mesh fines.

[0047] The clarifying agent includes fluorite, antimony oxide, cerium oxide and barium nitrate, and the mass ratio is 2:2:3:3.

[0048] Preparation:

[0049] Step 1, mixing silica, calcite, soda ash, alumina, potassium oxide, zinc oxide, hydrated sodium borate, and clarifying agent uniformly in proportion, a...

Embodiment 2

[0053] A high-quality wine red glass, including the following raw materials by weight:

[0054] Silica: 67 parts;

[0055] Calcite: 10 servings;

[0056] Soda ash: 14 parts;

[0057] Alumina: 2 parts;

[0058] Potassium oxide: 2 parts;

[0059] Zinc oxide: 2 parts;

[0060] Sodium borate hydrate; 2 parts;

[0061] Clarifying agent: 0.5 part;

[0062] Coloring masterbatch: 0.5 part;

[0063] The preparation method of described coloring masterbatch is:

[0064] Titanium dioxide, white carbon black, manganese oxide, and water glass are mixed in a mass ratio of 7:3:40:50, melted by heating at 1100°C, quenched and cooled in water, dried and broken into 30 mesh fines.

[0065] The clarifying agent includes fluorite, antimony oxide, cerium oxide and barium nitrate, and the mass ratio is 2:2:3:3.

[0066] Preparation:

[0067] Step 1, mixing silica, calcite, soda ash, alumina, potassium oxide, zinc oxide, hydrated sodium borate, and clarifying agent uniformly in proportion, ...

Embodiment 3

[0071] A high-quality wine red glass, including the following raw materials by weight:

[0072] Silica: 72 parts;

[0073] Calcite: 6 servings;

[0074] Soda ash: 12 parts;

[0075] Alumina: 2 parts;

[0076] Potassium oxide: 2 parts;

[0077] Zinc oxide: 2 parts;

[0078] Sodium borate hydrate; 2 parts;

[0079] Clarifying agent: not added, 0 parts;

[0080] Coloring masterbatch: 1 part;

[0081] The preparation method of described coloring masterbatch is:

[0082] Titanium dioxide, white carbon black, manganese oxide, and water glass are mixed in a mass ratio of 7:3:40:50, melted by heating at 1100°C, quenched and cooled in water, dried and broken into 30 mesh fines.

[0083] Preparation:

[0084] Step 1: Mix silica, calcite, soda ash, alumina, potassium oxide, zinc oxide, and hydrated sodium borate uniformly in proportion, and heat to 1450-1650° C. in a glass furnace to melt into glass liquid;

[0085] In step 2, the high-temperature glass liquid melted in step 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com