Composite decalcifying agent for calcified anaerobic granular sludge and decalcifying regeneration process

A technology of anaerobic granular sludge and composite decalcifying agent, applied in biological sludge treatment, anaerobic digestion treatment, water/sludge/sewage treatment, etc., can solve granular sludge calcification and reduce anaerobic granular sludge Inorganic component content and other issues, to achieve simple operation, ensure long-term stable and efficient treatment, and avoid adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: waste paper pulping wastewater treatment

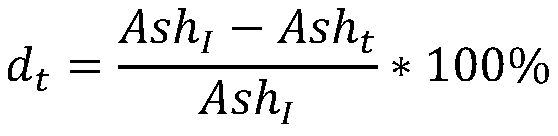

[0034] 1) The initial ash content of anaerobic granular sludge is 0.64g / gTS;

[0035] 2) The typical wastewater quality of waste paper pulping is COD 1500-5000mg / L, Ca 2+ 300-1200mg / L, total phosphorus 0.5-2mg / L, pH value 6.2-7.5;

[0036] 3) Since the pH value of the wastewater is close to the suitable range of anaerobic pH value, the composite decalcifying agent for calcified anaerobic granular sludge needs to be close to neutral. The formula shown is as follows: 65 parts of phosphoric acid, 25 parts of sodium tripolyphosphate, lignin 10 parts of sodium sulfonate, dissolved in water and mixed uniformly to obtain a composite decalcifying agent;

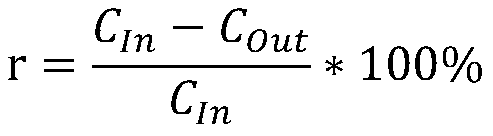

[0037] 4) According to the actual calcium ion concentration of the wastewater, calculate the dosage of the composite decalcifying agent per ton of water according to the mass ratio of calcium to phosphorus of 10-25:1, and add it to the influent adjustment tank of the a...

Embodiment 2

[0041] Embodiment 2: landfill leachate treatment

[0042] 1) The initial ash content of anaerobic granular sludge is 0.55g / gTS;

[0043] 2) Typical waste water quality of landfill leachate is COD 5000-20000mg / L, Ca 2+ 250-800mg / L, total phosphorus 5-25mg / L, ammonia nitrogen 400-1600mg / L, pH value 8.0-8.5;

[0044] 3) Since the pH value of the wastewater is alkaline and the concentration of ammonia nitrogen is high, free ammonia will be inhibited under alkaline conditions. Therefore, the composite decalcifying agent for calcified anaerobic granular sludge needs to be acidic. The formula shown is as follows: 85 parts of phosphoric acid , 10 parts of sodium tripolyphosphate, 5 parts of sodium lignosulfonate, dissolved in water and mixed uniformly to obtain a composite decalcifying agent;

[0045] 4) According to the actual calcium ion concentration of the wastewater, calculate the dosage of the composite decalcifying agent per ton of water according to the mass ratio of calcium...

Embodiment 3

[0049] Embodiment 3: fermentation wastewater treatment

[0050] 1) The initial ash content of anaerobic granular sludge is 0.43g / gTS;

[0051] 2) The typical wastewater quality of fermentation wastewater is COD 18000-40000mg / L, Ca 2+ 250-1000mg / L, total phosphorus 15-45mg / L, ammonia nitrogen 13000-16000mg / L, pH value 2.2-2.6;

[0052] 3) Since the pH value of the wastewater is acidic, the composite decalcifying agent for calcified anaerobic granular sludge needs to be alkaline, and the formula shown is as follows: 40 parts of phosphoric acid, 15 parts of sodium tripolyphosphate, and 1 part of sodium lignosulfonate , add water to dissolve and mix evenly to obtain a composite decalcifying agent;

[0053] 4) According to the actual calcium ion concentration of the wastewater, calculate the dosage of the composite decalcifying agent per ton of water according to the mass ratio of calcium to phosphorus of 10-25:1, and add it to the inlet pool of the anaerobic reactor;

[0054] 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com