Preparation method of acrylamide monomer polybasic copolymer microspheres

A multi-component copolymer and acrylamide technology, applied in the field of copolymers, can solve the problems of complicated post-processing process, inconvenient industrial production, poor polymer morphology, etc., and achieve the effects of controllable morphology, easy separation, and narrow size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] With isoamyl acetate as the solvent of the reaction system, styrene 1.32g, maleic anhydride 1.0g, acrylamide 0.18g, initiator azobisisobutyronitrile 0.025g are dissolved in 23g of isoamyl acetate, ultrasonically It is fully dissolved and mixed evenly. The molar ratio of styrene, maleic anhydride and acrylamide in the reaction system is 5:4:1; nitrogen gas is passed through the system for 20 minutes, the reaction temperature is 75°C, and the reaction time is 8 hours. After the reaction is completed, the The reaction product was centrifuged at 5000 rpm for 5 minutes, washed with petroleum ether, centrifuged three times, and vacuum-dried to constant weight to obtain a St-MAH-AM copolymer with a yield of 99% and an average particle size of 271nm .

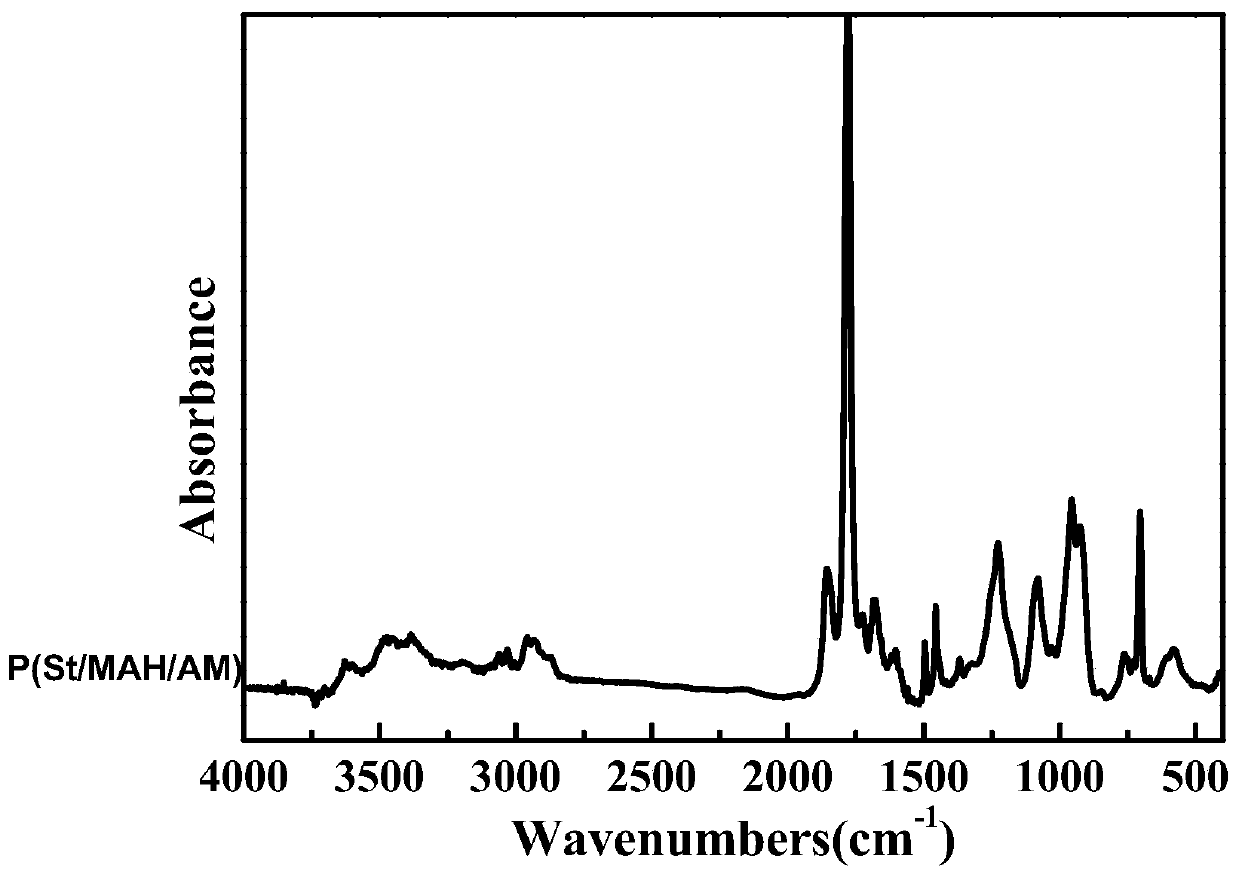

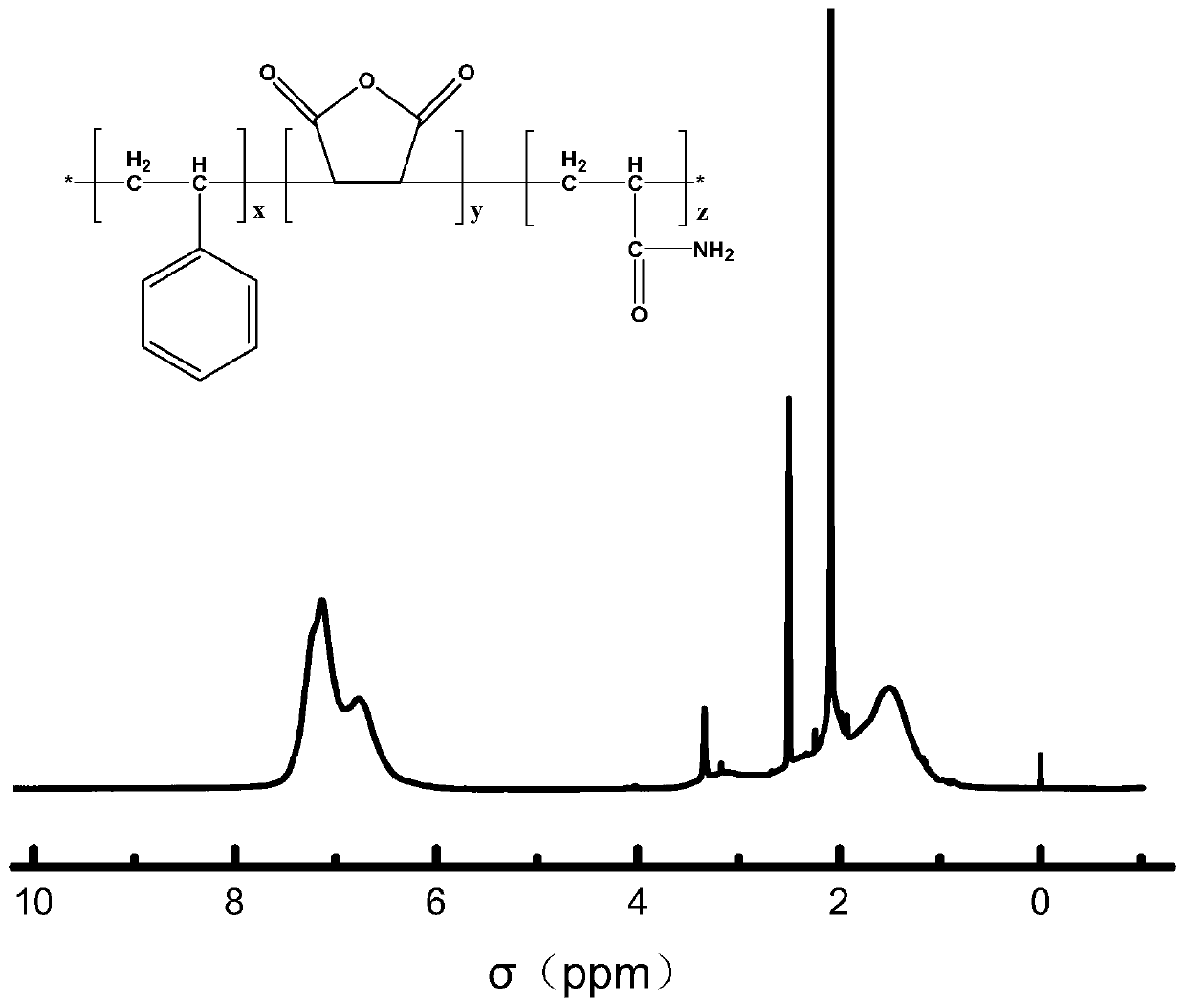

[0030] figure 1 Is the infrared spectrum of the St-MAH-AM copolymer, where 3061, 3031cm -1 The peak at corresponds to the stretching vibration absorption peak of the C-H bond on the benzene ring, 762, 704cm -1 The peaks at co...

Embodiment 2-15

[0032] The formulas used in Examples 2-15 are shown in Table 1. The implementation steps are basically the same as in Example 1. Different copolymer compositions are prepared by changing the monomer ratio, medium type, monomer type, monomer concentration, and initiator type. and copolymer microspheres of different particle sizes.

[0033] Table 1 Polymerization system formula

[0034]

[0035]

[0036]

Embodiment 16

[0037] Embodiment 16 (comparative example)

[0038] With isoamyl acetate as the solvent of the reaction system, 1.49g of styrene, 1.01g of acrylamide and 0.025g of initiator azobisisobutyronitrile were dissolved in 23g of isoamyl acetate, no electron-accepting monomer was added, and ultrasonic Make it fully dissolve and mix evenly. The molar ratio of styrene and acrylamide in the reaction system is 1:1; the system is blown with nitrogen for 20 minutes, the reaction temperature is 75°C, and the reaction time is 8 hours. Figure 4 Scanning electron micrographs of the reaction products, with image 3 The comparison shows that the morphology of the copolymer is poor, and it is irregular particles, indicating that the lack of electron-accepting monomers leads to unstable particle growth during the polymerization process, and polymer microspheres cannot be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com