Novel method for reducing nitrogen loss in composting process of perishable garbage

A technology of waste composting and new method, which is applied in fertilization devices, fertilizer mixtures, and agricultural gas emission reduction, etc., can solve the problems of reducing the pH value of composting materials, affecting the activity of microorganisms, and easily producing secondary pollution. The effect of improving water holding capacity and improving field climate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

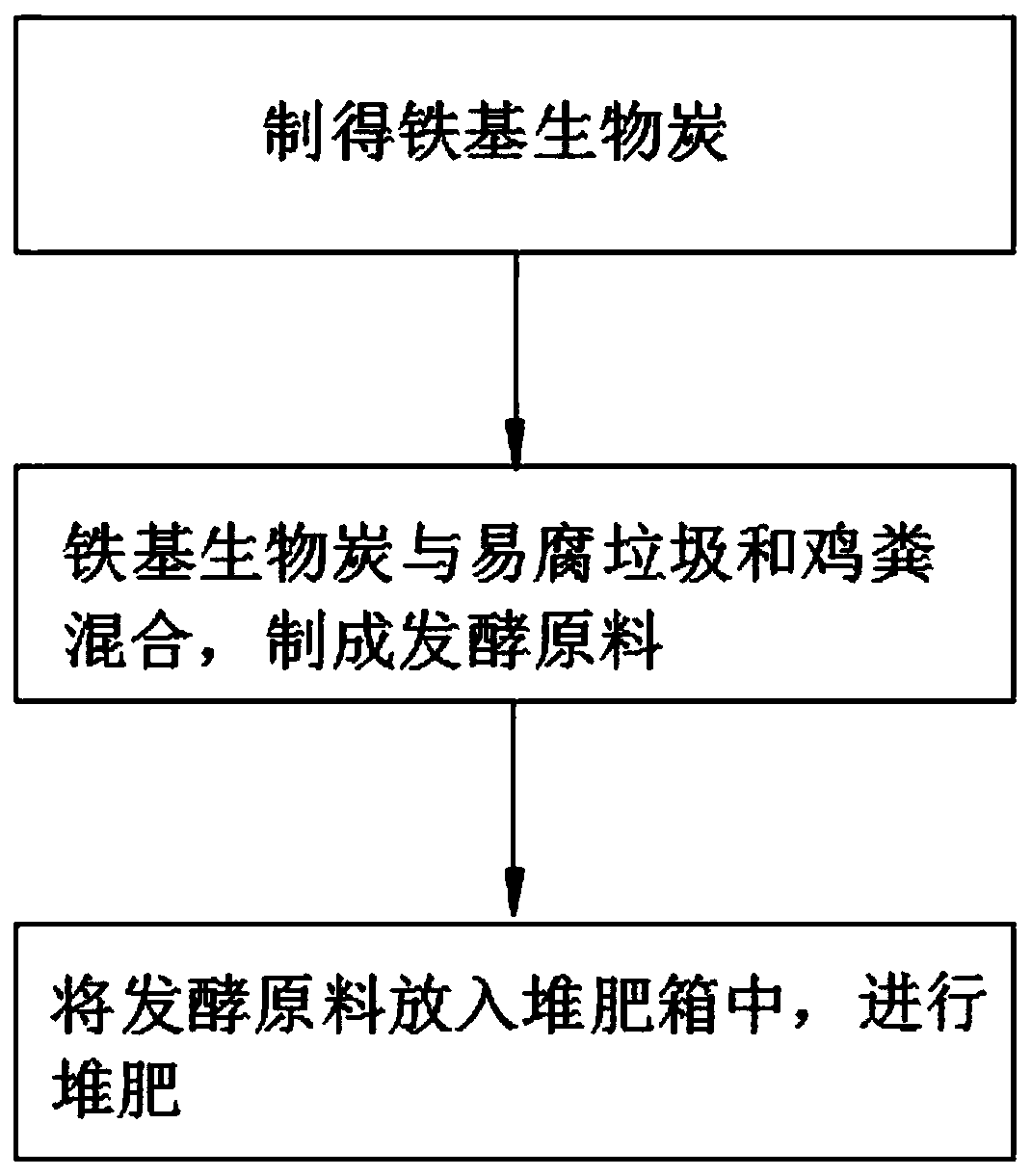

[0037] Such as figure 1 Shown, the present invention provides a kind of new method that reduces nitrogen loss in the perishable garbage composting process, and the concrete steps of new method are as follows:

[0038] Step 1: Add Fenton's reagent to the original sludge for deep dehydration conditioning. After stirring, dehydrate the plate and frame under the dehydration pressure of 0.8MPa and the diaphragm squeeze pressure of 1.2MPa to make mud cakes; take out the mud cakes, dry them, grind them, and pass them 80-mesh sieve, fired in a tubular or horizontal pyrolysis experimental furnace at 800°C for 2 hours to obtain iron-based biochar;

[0039] Step 2: After mixing the iron-based biochar prepared in Step 1 with perishable garbage and chicken manure to form a mixture, adjust the moisture content to 40-50% to obtain fermentation raw materials;

[0040] Step 3: Add the fermentation raw materials into the compost bin; during the composting process, use the stirring shaft to sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com