Preparation method and application of a milk-derived active peptide

An active peptide and milk-derived technology, applied in the direction of microbial-based methods, biochemical equipment and methods, applications, etc., can solve problems such as intestinal mucosal barrier dysfunction, low yield, intestinal structure and function damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Use soybean protein as raw material, add distilled water according to the ratio of soybean protein: water = 1:4, and pretreat at 85°C for 3 hours. Cool to 45°C, adjust the pH of the system to about 3.0 with 2mol / L HCl solution, add acid protease at an enzyme concentration of 5000 U per gram of raw material, keep the temperature at about 45°C, and react for 10 hours. Use casein as raw material, add distilled water according to the ratio of casein: water = 1:10, adjust the pH of the system to about 8.0 with 2mol / L NaOH solution, add trypsin according to the enzyme concentration of 1500U per gram of raw material, and maintain the temperature at 45 ℃, react for 2 hours. Mix 1 volume of soybean protein hydrolyzate with 2 volumes of casein hydrolyzate for later use. Prepare the fermentation medium according to the ratio of 4g of bran, 1g of soybean meal powder, 4g of ammonium sulfate, 0.3g of dipotassium hydrogen phosphate, 0.5g of calcium chloride, and 125ml of distilled wa...

Embodiment 2

[0022] Using soybean protein as raw material, add distilled water according to the ratio of soybean protein: water = 1:2, and pretreat at 90°C for 4 hours. Cool to 45°C, adjust the pH of the system to about 4.0 with 2mol / L HCl solution, add acid protease at an enzyme concentration of 5500 U per gram of raw material, keep the temperature at about 45°C, and react for 12 hours. Use casein as raw material, add distilled water according to the ratio of casein: water = 1:5, adjust the pH of the system to about 9.0 with 2mol / L NaOH solution, add trypsin according to the enzyme concentration of 2000U per gram of raw material, and maintain the temperature at 50 ℃, react for 5 hours. Mix 1 volume of soybean protein enzymatic hydrolyzate with 5 volumes of casein enzymatic hydrolyzate for later use. Prepare the fermentation medium according to the ratio of 4g of bran, 1g of soybean meal powder, 4g of ammonium sulfate, 0.3g of dipotassium hydrogen phosphate, 0.5g of calcium chloride, and ...

Embodiment 3

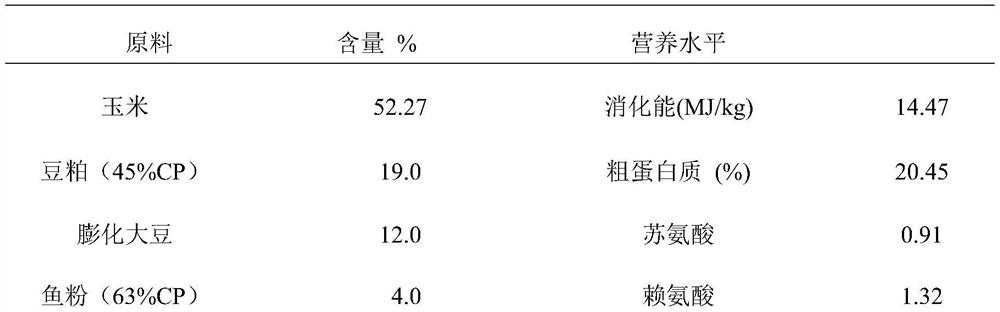

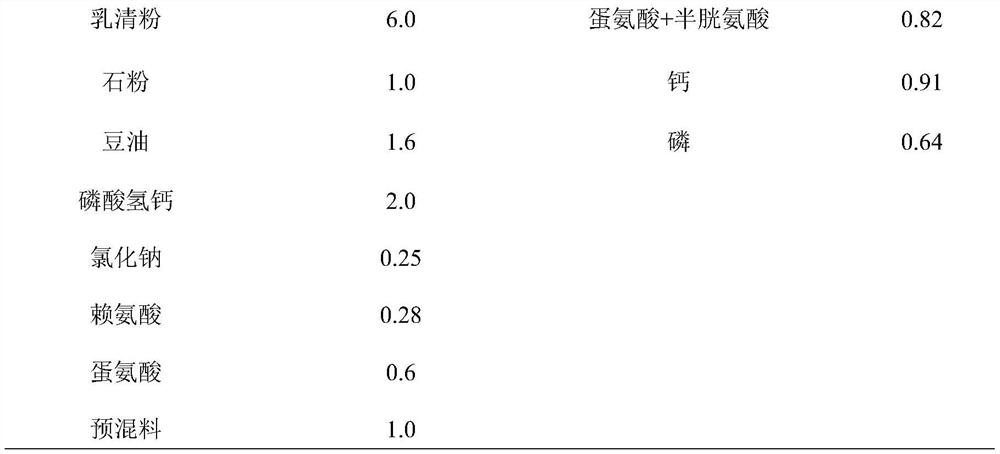

[0024] At the beginning of weaning of 25-day-old piglets, the control group was fed the control diet (see Table 1 for formula). The full-price feed of the test group was supplemented with 400 grams of milk-derived active peptide per ton of the diet of the control group, and the above-mentioned feed was fed until the age of 46 days, and the growth performance of piglets was measured.

[0025] Table 1 Test diet composition and nutritional indicators

[0026]

[0027]

[0028]The test results showed that compared with the control group, the average daily gain of the piglets in the experimental group increased by 31.67% (P0.05). Duodenal chymotrypsin, lipase and trypsin increased by 49.35% (P<0.05), 40.00% (P<0.05) and 38.40% (P<0.05) respectively compared with the control group. The spleen index increased by 32.00% (P<0.05), and the mandibular lymphatic index increased by 37.50% (P<0.05). Compared with the control group, serum IgG increased by 89.83% (P<0.01), and jejunum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com