Preparation method of one-dimensional nano magnetons with stable solution dispersity

A dispersive, nano-magnetic technology, applied in chemical instruments and methods, dissolution, mixers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

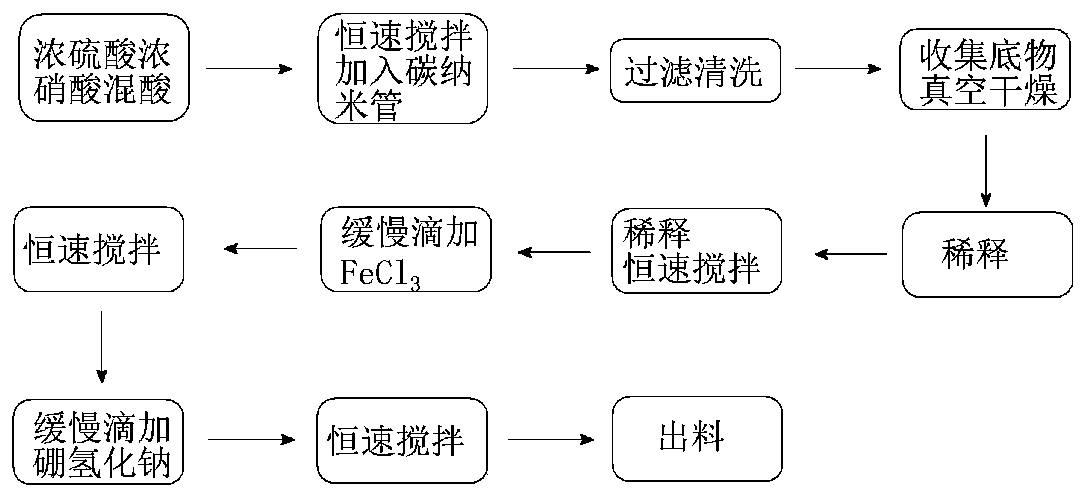

[0015] The technical process of the one-dimensional nanomagnet preparation method with stable solution dispersion involved in this embodiment includes two steps: the preparation of water-soluble carbon nanotube carrier and the preparation of nanomagnet by concentrated acid oxidation method:

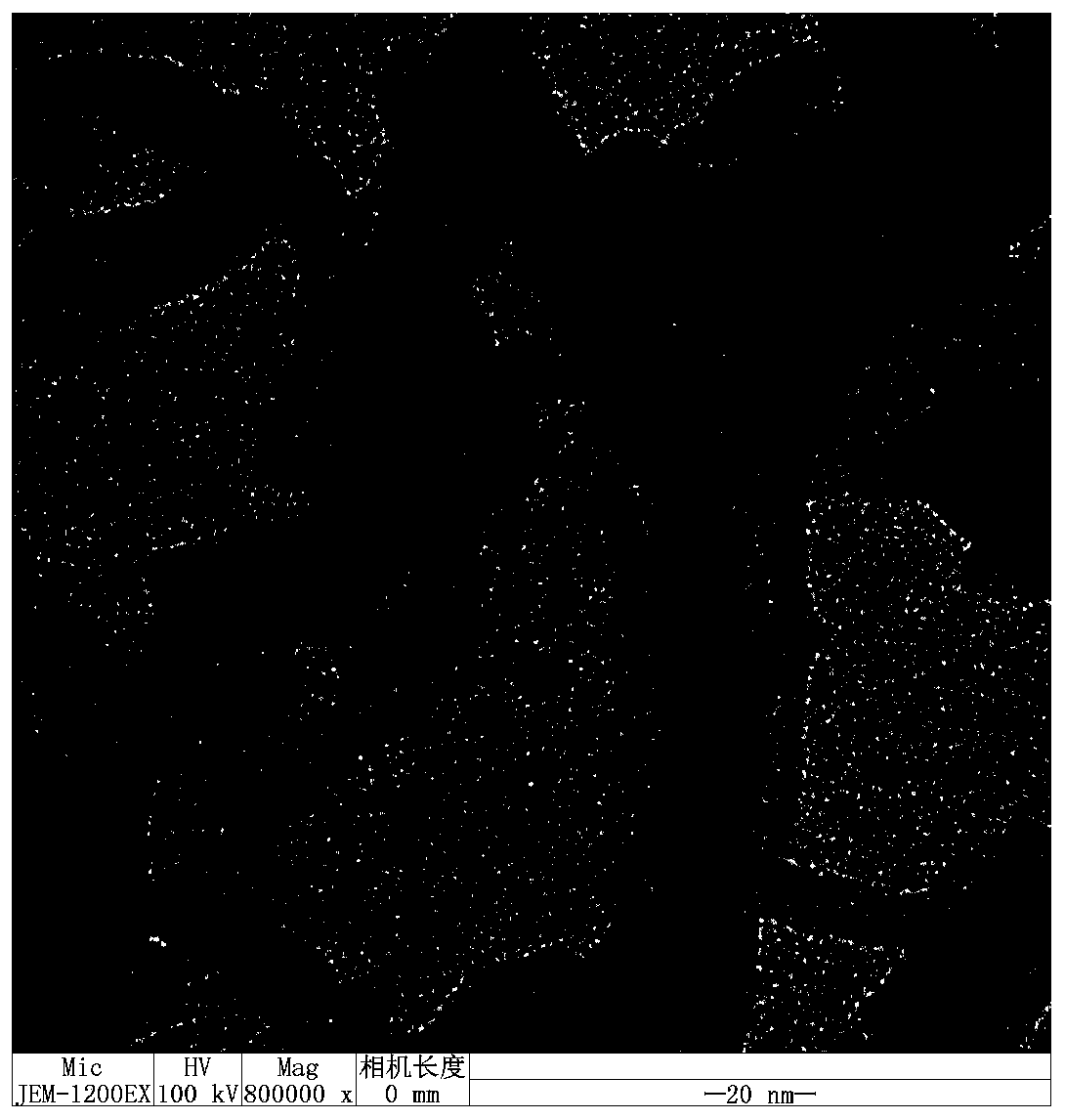

[0016] (1) Preparation of water-soluble carbon nanotube carrier by concentrated acid oxidation method: disperse 5g of carbon nanotubes in 200g of nitric acid and sulfuric acid with a volume ratio of 1:3 under the condition of magnetic stirring at a temperature of 70°C and a rotation speed of 300rpm to form Stand still in the concentrated acid for 8-12h to form oxidized carbon nanotube slurry, disperse the oxidized carbon nanotube slurry in deionized water, wash it through a filter membrane until neutral, collect the substrate and dry it in vacuum at a temperature of 50-80°C Dry in the box for 24 hours to obtain oxidized carbon nanotube powder, which is dissolved in water to obtain a water-...

Embodiment 2

[0019] The technical process of the one-dimensional nanomagnet preparation method with stable solution dispersion involved in this embodiment includes two steps of preparing water-soluble carbon nanotube carrier and preparing nanomagnet by macromolecular coating method:

[0020] (1) Preparation of water-soluble carbon nanotube carrier by macromolecular coating method: disperse 0.1 g of carbon nanotubes in 100 g of poly(styrene-p-styrene sulfonate) with a concentration of 2 g / L under magnetic stirring conditions of 300 rpm NaCl) aqueous solution, ultrasonication for 30min, suction filtration and water washing three times, the collected substrate was vacuum-dried at 55°C for 24h to obtain macromolecule-coated carbon nanotube powder, which was dissolved in water to obtain water-soluble carbon with a mass percentage concentration of 0.1%. Nanotube carrier;

[0021](2) Preparation of nanomagnets: under the stirring condition of 300rpm, add FeCl dropwise in the water-soluble carbon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com