Hexagonal column type WO3/Bi2WO6 composite photoelectrode film preparation method

A technology of electrode film and composite light, which is applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problem of no hexagonal column shape, etc., and achieve the effect of good light stability, controllable conditions, and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] A hexagonal column type WO 3 / Bi 2 WO 6 The preparation method of composite photoelectrode thin film, concrete steps are as follows:

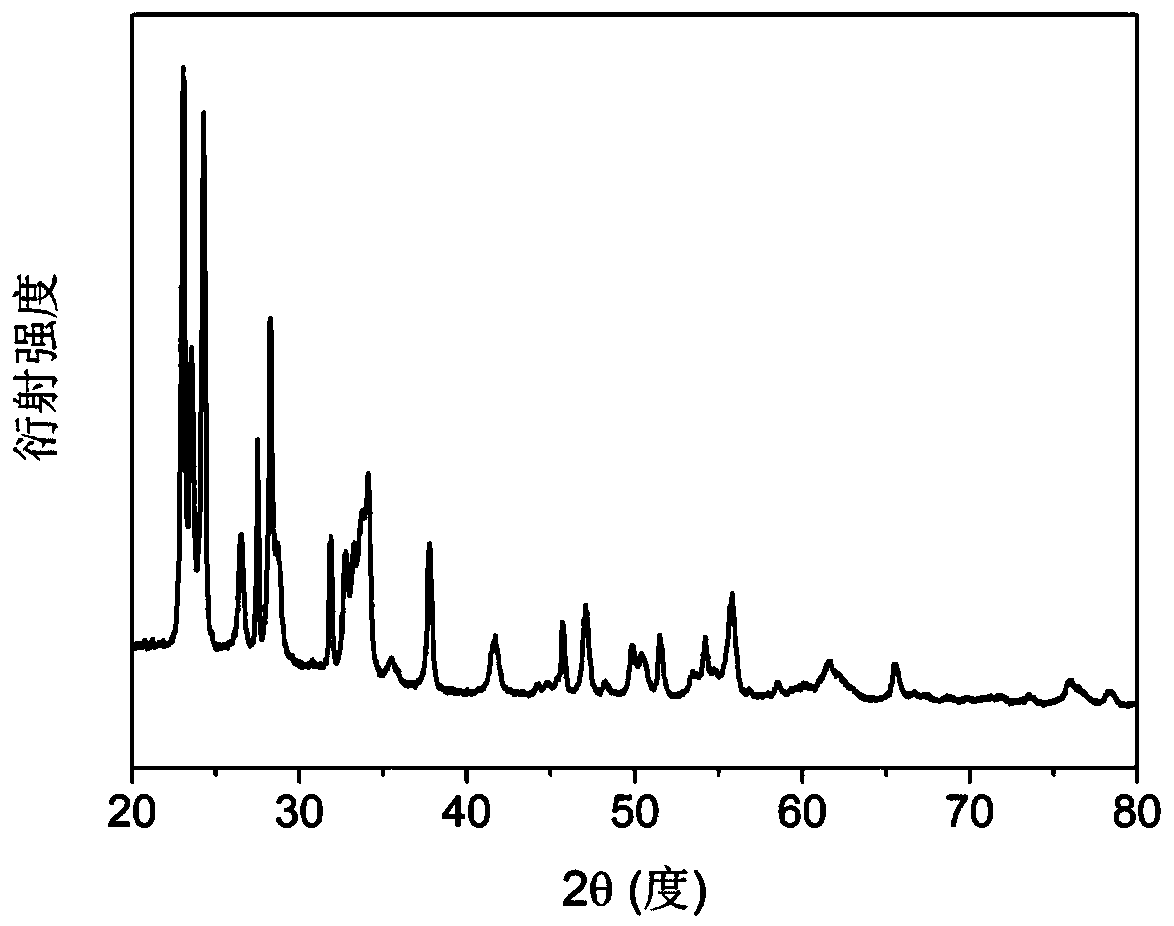

[0017] At room temperature, respectively configure 15ml of sodium tungstate with a concentration of 25mmol / L and an aqueous ammonium oxalate solution with a concentration of 55mmol / L, slowly add 5ml of hydrochloric acid solution (3mol / L) into the sodium tungstate solution, stir evenly, and then Mix with ammonium oxalate solution and stir for 30 minutes; then transfer the mixed solution to a hydrothermal reaction kettle, insert FTO conductive glass, place it in a constant temperature blast drying oven at 140°C for 6 hours, after cooling, wash with water, dry, and calcinate at 550°C 2.5h, get WO 3 Electrode; cut the electrode into small pieces of 1cm×2.5cm, add 150μL of acetic acid aqueous solution of bismuth nitrate with a concentration of 0.1mmol / L dropwise, dry at room temperature, calcinate at 550°C for 6h, and after cooling, use 0....

Embodiment 2

[0020] A hexagonal column type WO 3 / Bi 2 WO 6 Preparation method of composite photoelectrode thin film, WO 3 The preparation steps of the film are the same as in Example 1, and the WO 3 After the thin film electrode, prepare 50 ml of bismuth nitrate aqueous solution with a concentration of 0.1 mmol / L, and add concentrated acetic acid to adjust the pH to 0.6. Afterwards, pipette 100 μL of this solution into the WO 3 The surface of the thin film electrode was dried at room temperature, calcined at 650°C for 6h, and after cooling, was treated with 0.8mol / L HNO 3 Soak for 15h to remove Bi on the surface 2 o 3 Get WO 3 / Bi 2 WO 6 film.

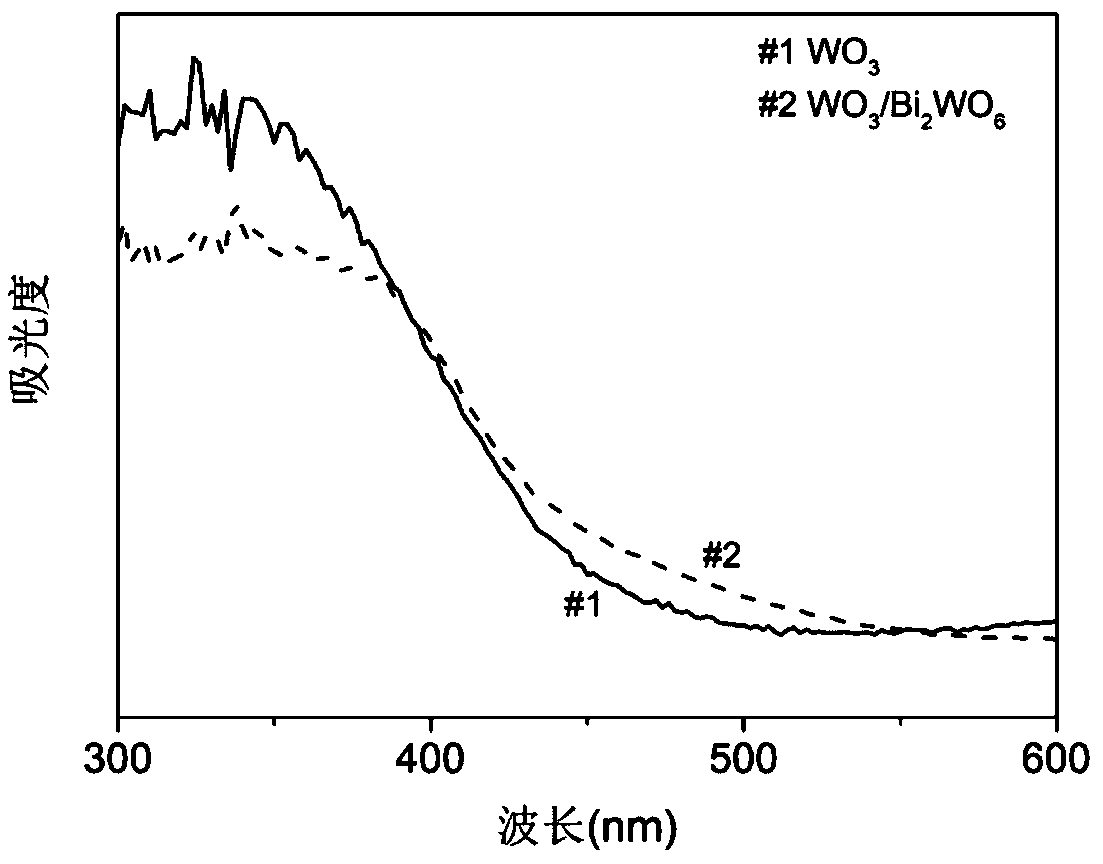

[0021] figure 2 WO prepared for 3 and WO 3 / Bi 2 WO 6 The UV-Vis diffuse reflectance map of the film electrode, it is obvious that as the wavelength decreases, the WO 3 and WO 3 / Bi 2 WO 6 The absorbance of the film electrode increases gradually, and the WO 3 The band edge absorbs at 470nm, while WO 3 / Bi 2 WO 6 The absorpt...

Embodiment 3

[0023] A hexagonal column type WO 3 / Bi 2 WO 6 Preparation method of composite photoelectrode thin film, WO 3 The preparation steps of the film are the same as in Example 1, and the WO 3 After the thin film electrode, prepare 50 ml of bismuth nitrate aqueous solution with a concentration of 0.02 mmol / L, and add concentrated acetic acid to adjust the pH to 0.5. Afterwards, pipette 200 μL of this solution into the WO 3 The surface of the thin film electrode was dried at room temperature, calcined at 600°C for 4h, and after cooling, was treated with 0.5mol / l HNO 3 Soak for 15h to remove Bi on the surface 2 o 3 Get WO 3 / Bi 2 WO 6 film.

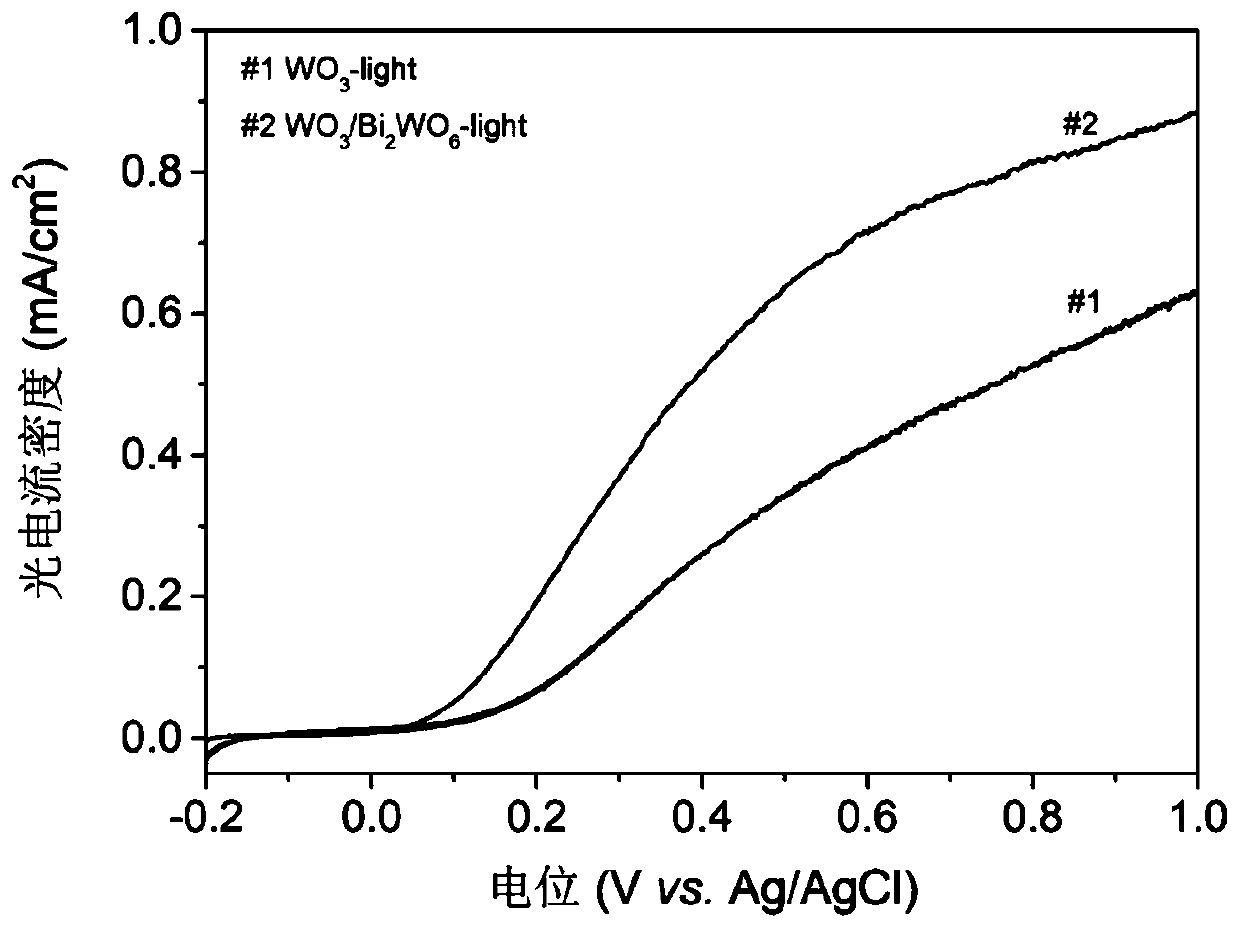

[0024] image 3 for WO 3 and WO 3 / Bi 2 WO 6 The linear sweep voltammetry curve of the film electrode, the sweep speed is 20mV / s, and the output intensity of the xenon light source is adjusted to 100mW / cm 2 , The supporting electrolyte is a sodium phosphate buffer solution with a pH equal to 7, and the concentration is 0.1mol / L. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com