Resin precoated sand easy to scatter

A technology of resin coating and coating sand is applied in the field of alloy casting, which can solve the problems of low pouring temperature, poor storage and low strength of aluminum alloy, and achieve the effects of improving tensile strength at room temperature, improving collapsing performance and simple preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

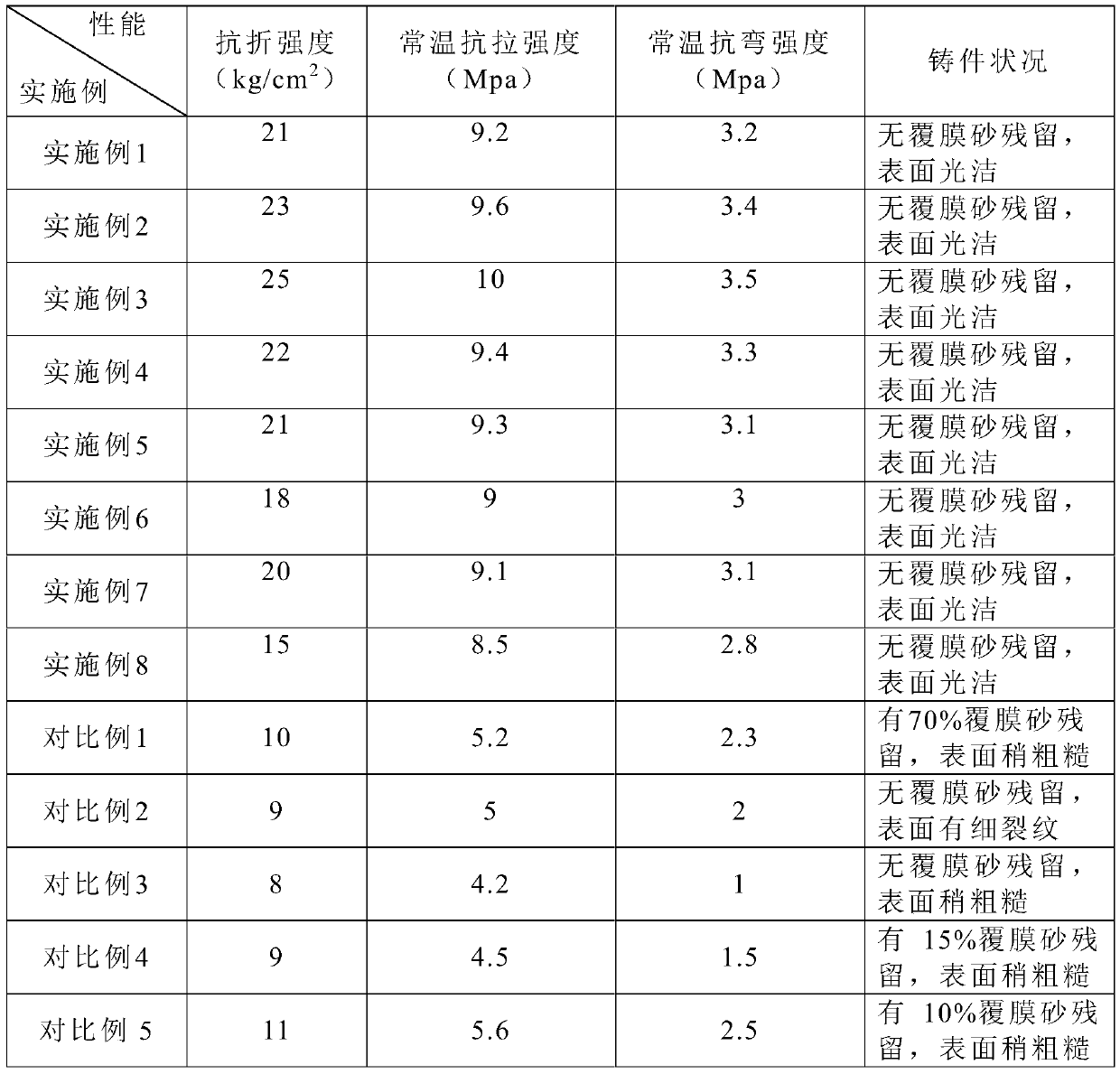

Examples

Embodiment 1

[0026] An easily collapsible resin-coated sand, comprising the following raw material components in parts by weight: 100 parts of sodium chloride with a particle size of 70 mesh, 2 parts of modified phenolic resin, and a 36% hexamethylenetetramine aqueous solution 0.2 part, 0.08 part of calcium stearate, 0.1 part of disintegrating agent, 0.5 part of cocoyl glucoside, and 0.1 part of CaO, wherein the disintegrating agent is composed of talcum powder and potassium permanganate according to the mass percentage of 12% and 88% respectively. become;

[0027] The modified phenolic resin is modified by the following method: react phenol and modifier under the action of a catalyst for 1.5 hours, then add formaldehyde, stir well, add hydrochloric acid to adjust the pH to 1.5, react for 1 hour, vacuum dehydrate, add absolute ethanol and stir to dissolve , cooled to room temperature and discharged; wherein the mass ratio of phenol, modifier, and formaldehyde is 15.5:1:16, and the modifier...

Embodiment 2

[0030] An easily collapsible resin-coated sand, comprising the following raw material components in parts by weight: 100 parts of sodium chloride with a particle size of 90 mesh, 3 parts of modified phenolic resin, and a hexamethylenetetramine aqueous solution with a concentration of 37%. 0.4 part, 0.1 part of calcium stearate, 0.2 part of disintegrating agent, 0.8 part of cocoyl glucoside, 0.1 part of CaO, 0.2 part of MgO, wherein the disintegrating agent is composed of talcum powder and potassium permanganate by mass percentage of 15% and 85% respectively. % compounded;

[0031] The modified phenolic resin is modified by the following method: react phenol and modifier under the action of a catalyst for 1.5 hours, then add formaldehyde, stir well, add hydrochloric acid to adjust the pH to 1.7, react for 1 hour, vacuum dehydrate, add absolute ethanol and stir to dissolve , cooled to room temperature and discharged; wherein the mass ratio of phenol, modifier, and formaldehyde i...

Embodiment 3

[0034] An easily collapsible resin-coated sand, comprising the following raw material components in parts by weight: 100 parts of sodium chloride with a particle size of 100 mesh, 4 parts of modified phenolic resin, and a 38% hexamethylenetetramine aqueous solution 0.6 part, 0.2 part of calcium stearate, 0.3 part of disintegrating agent, 1 part of cocoyl glucoside, 0.1 part of CaO, 0.2 part of MgO, 0.2 part of BaO, wherein the disintegrating agent is composed of talcum powder and potassium permanganate according to mass percentage 20% and 80% compound;

[0035] The modified phenolic resin is modified by the following method: react phenol and modifier for 2 hours under the action of a catalyst, then add formaldehyde, stir well, add hydrochloric acid to adjust the pH to 2, react for 1.5 hours, vacuum dehydrate, add absolute ethanol and stir to dissolve , cooled to room temperature and discharged; wherein the mass ratio of phenol, modifier, and formaldehyde is 16:1:17, and the mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com