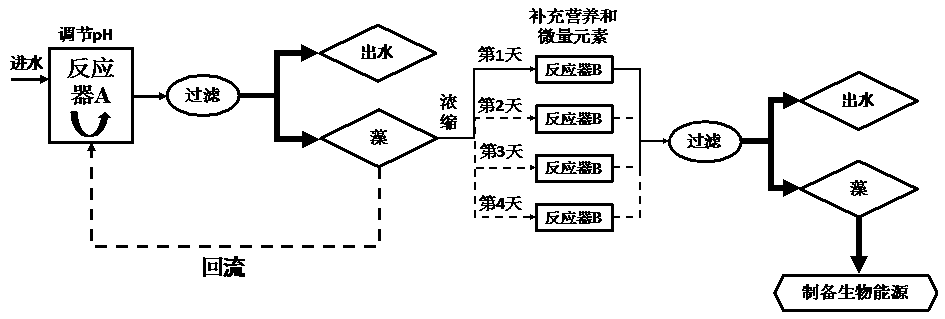

Method for producing algae-derived saccharide with coupling and for purifying secondary tail water or sludge supernate

A technology of algae-derived sugar and tail water, applied in the direction of microorganism-based methods, chemical instruments and methods, biochemical equipment and methods, etc., can solve the problems of compressed economic and ecological benefits, high cultivation costs, etc., to shorten the production cycle, reduce The effect of training costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The concentration of inorganic nitrogen (nitrate nitrogen, ammonia nitrogen) in the sludge supernatant of a sewage treatment plant is about 19.8 mg / L, and the concentration of phosphate is about 3.45 mg / L. The volume of reactor A is 10 L, the concentration of microalgae chlorophyll a is set to 4-5 mg / L, the light is 15000-20000 lx, the light-dark cycle is 16h:8h, the temperature is 28°C, the pH is adjusted to about 8, and aeration is performed. In order to ensure that the concentration of nitrogen and phosphorus in the effluent of reactor A basically meets the requirements of the quality standard for Class V functional waters in the Environmental Quality Standard for Surface Water (GB3838-2002), the hydraulic retention time is set to 4 days. Reactor A has been running continuously for about 30 days. After the initial 2-3 days of adaptation period, the effluent water quality is stable, including 0.4-1.3 mg / L of inorganic nitrogen and 93.4-98.0% removal rate; 0.10-0.25 mg / ...

Embodiment 2

[0028] The concentration of inorganic nitrogen (nitrate nitrogen, ammonia nitrogen) in the secondary tail water of a sewage treatment plant is about 5.1 mg / L, and the concentration of phosphate is about 0.52 mg / L. The volume of reactor A is 10 L, the concentration of microalgae chlorophyll a is set to 2.5-3.0 mg / L, the light is 10000-12000lx, the light-dark cycle is 14h:10h, the temperature is 28°C, the pH is adjusted to about 8, and aeration is performed. In order to ensure that the concentration of nitrogen and phosphorus in the effluent of reactor A basically meets the requirements of the quality standard for V functional waters in the Environmental Quality Standard for Surface Water (GB3838-2002), the hydraulic retention time is set to 1 day. Reactor A has been running continuously for about 30 days. After the initial 2-3 days of adaptation period, the effluent water quality is stable, including inorganic nitrogen 0.20-0.72 mg / L, removal rate of 85.9-96.0%; phosphate 0.03-0...

Embodiment 3

[0031] 1.2 g of the algae flour produced by the algae flour reactor B collected in Example 1 was directly dissolved in 40 ml of 5% (v / v) sulfuric acid solution to prepare a 30 g / L algae liquid. High temperature hydrolysis at 121°C for 30 min, the hydrolyzate was filtered through a 0.45 μm filter membrane, the hydrolyzate was adjusted to pH=6.5±0.2 with NaOH solid, Saccharomyces cerevisiae was added, and fermentation was carried out at 35°C at a speed of 150 r / min for 72 h. At the same time, the algae powder produced by reactor A was hydrolyzed and fermented under the same conditions.

[0032] 30 g / L Reactor B algae powder produced bioethanol concentration of 8.44 g / L, ethanol yield was 28.1 %, while 30 g / L Reactor A algae powder produced bioethanol concentration was only 0.93 g / L, ethanol yield was 3.1%. After being cultured in reactor B, the ethanol production rate of microalgae was significantly improved. The potential of the microalgae cultivated by this process to produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com