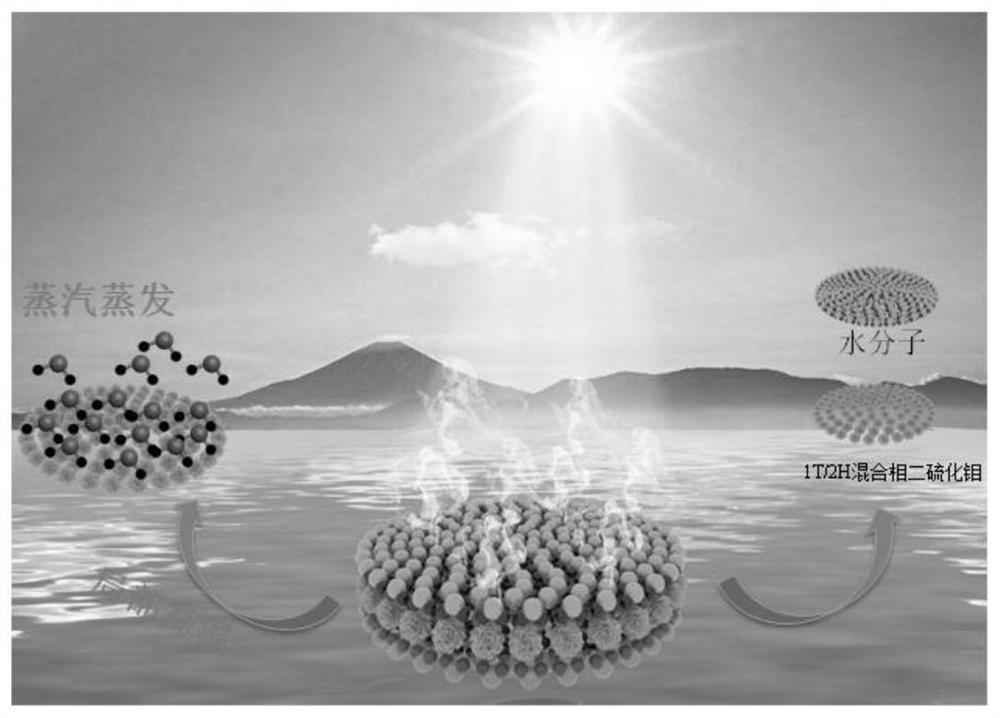

A 1t/2h mixed-phase molybdenum disulfide material and its preparation method and application

A molybdenum disulfide and mixed-phase technology, applied in chemical instruments and methods, water/sewage treatment, general water supply conservation, etc., can solve the problems of inability to achieve full-spectrum solar energy absorption, complex preparation process, large energy band gap, etc. High-efficiency solar vapor concentration, high photothermal conversion efficiency, and enhanced solar absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

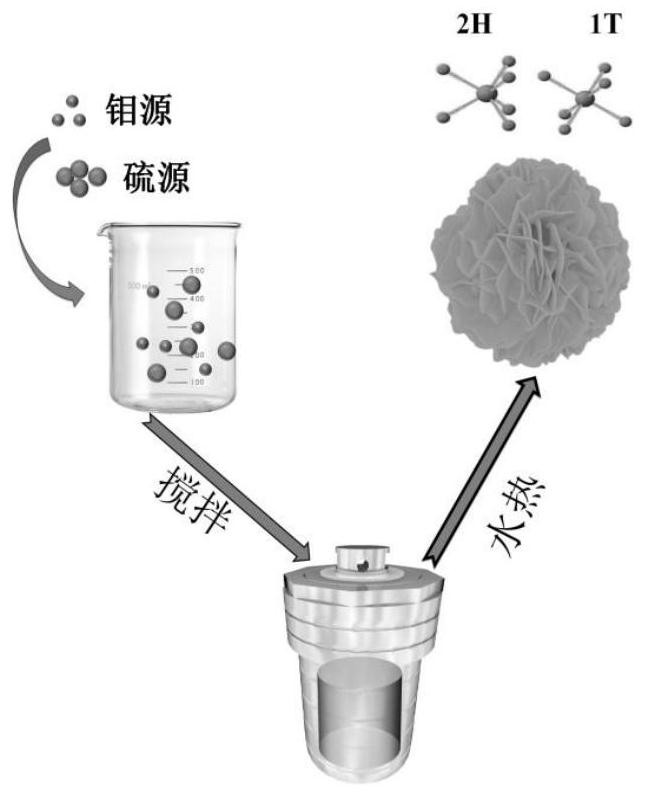

[0038] The present invention also provides a preparation method of the IT / 2H mixed phase molybdenum disulfide material described in the above technical solution, comprising the following steps:

[0039] The molybdenum source, sulfur source and water are mixed, followed by hydrothermal reaction and first drying treatment to obtain 1T / 2H mixed phase molybdenum disulfide powder;

[0040] On the substrate, using the 1T / 2H mixed phase molybdenum disulfide powder to prepare a 1T / 2H mixed phase molybdenum disulfide thin film;

[0041] The 1T / 2H mixed-phase molybdenum disulfide film is subjected to a second drying treatment to obtain a 1T / 2H mixed-phase molybdenum disulfide material.

[0042] In the present invention, unless otherwise specified, all the preparation materials of the present invention are commercially available products well known to those skilled in the art.

[0043] In the invention, the molybdenum source, the sulfur source and water are mixed, and the hydrothermal r...

Embodiment 1

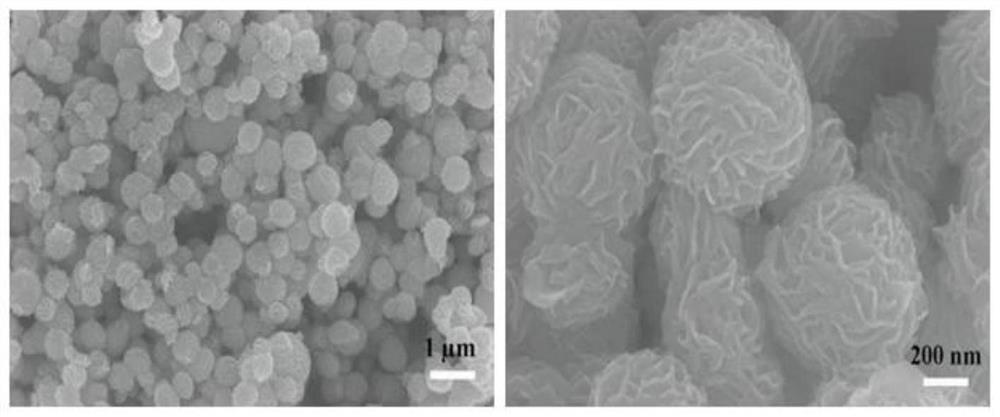

[0057] Mix 0.7g of ammonium molybdate, 0.6g of thioacetamide and 40mL of pure water under the condition of 500rpm magnetic stirring for 30 minutes to obtain a mixed solution; Thermal reaction for 20 hours, after the reaction was completed, naturally cool to room temperature, under the condition of 10000rpm centrifugal speed, alternately wash with water and ethanol for 4 times, and freeze-dry for 24 hours to obtain 1T / 2H mixed-phase molybdenum disulfide powder;

[0058] Ultrasonic disperse 10 mg of the obtained 1T / 2H mixed-phase molybdenum disulfide powder in 10 mL of water under the condition of an ultrasonic frequency of 40 kHz to obtain a dispersion liquid, and use a mixed cellulose filter membrane with a pore size of 0.22 μm as a substrate, and filter it under reduced pressure. Suction filter the dispersion on the substrate to obtain the IT / 2H mixed-phase molybdenum disulfide film, keep the substrate, and dry the sample including the substrate and the IT / 2H mixed-phase molyb...

Embodiment 2

[0076] The high-temperature hydrothermal reaction temperature is 160° C., and the rest of the preparation process is the same as in Example 1 to obtain a 1T / 2H mixed-phase molybdenum disulfide material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com