Self-supporting CoMoS<4> supercapacitor electrode material and preparation method and application thereof

A technology for supercapacitors and electrode materials, applied in the field of electrochemistry, can solve the problems of difficult residual liquid treatment compared with hydrothermal reaction systems, lower specific capacitance of supercapacitors, easy generation of toxic and harmful substances, etc., to improve capacitance performance and stability, The effect of improving specific capacitance and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

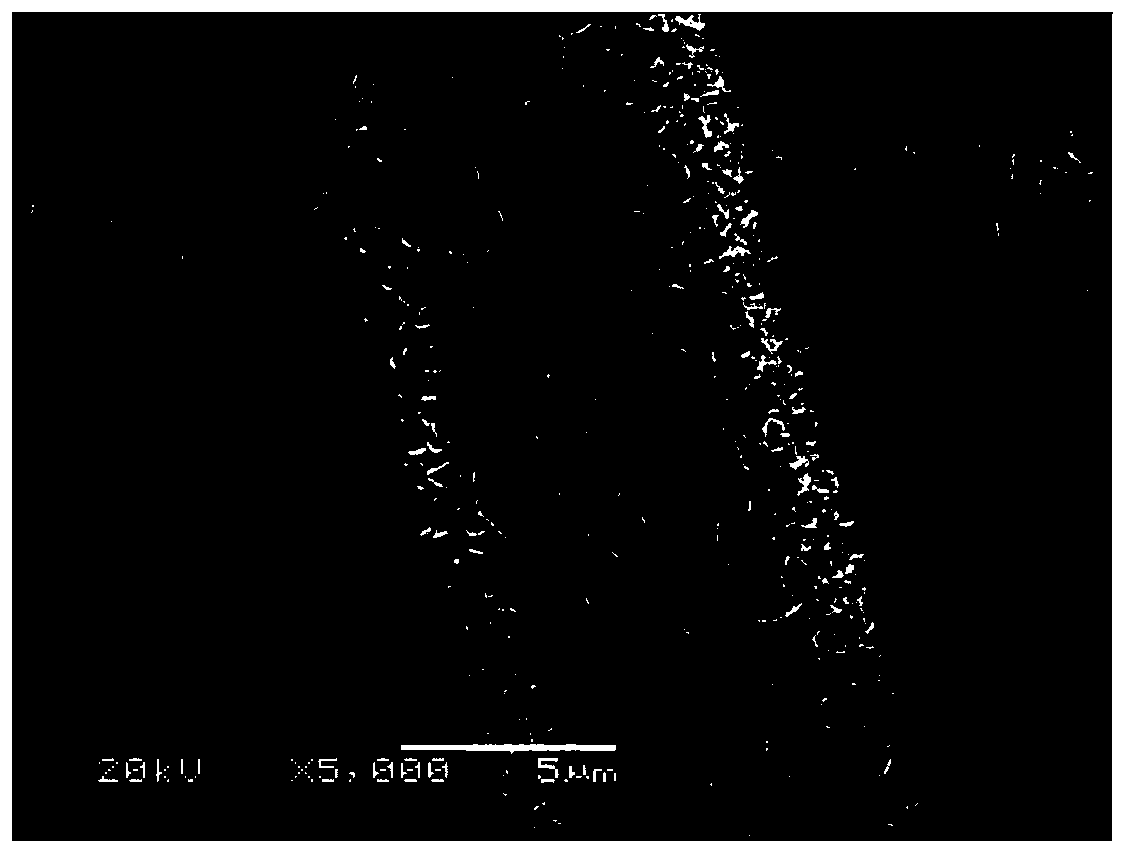

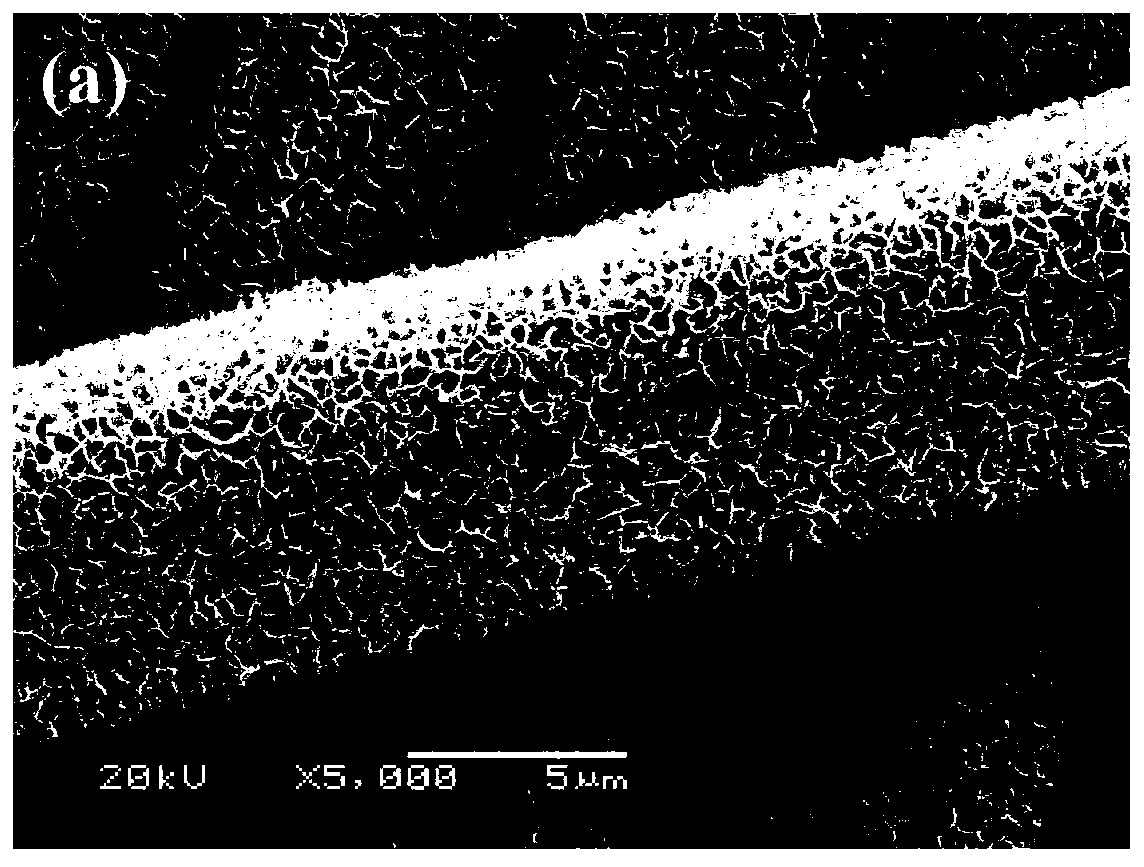

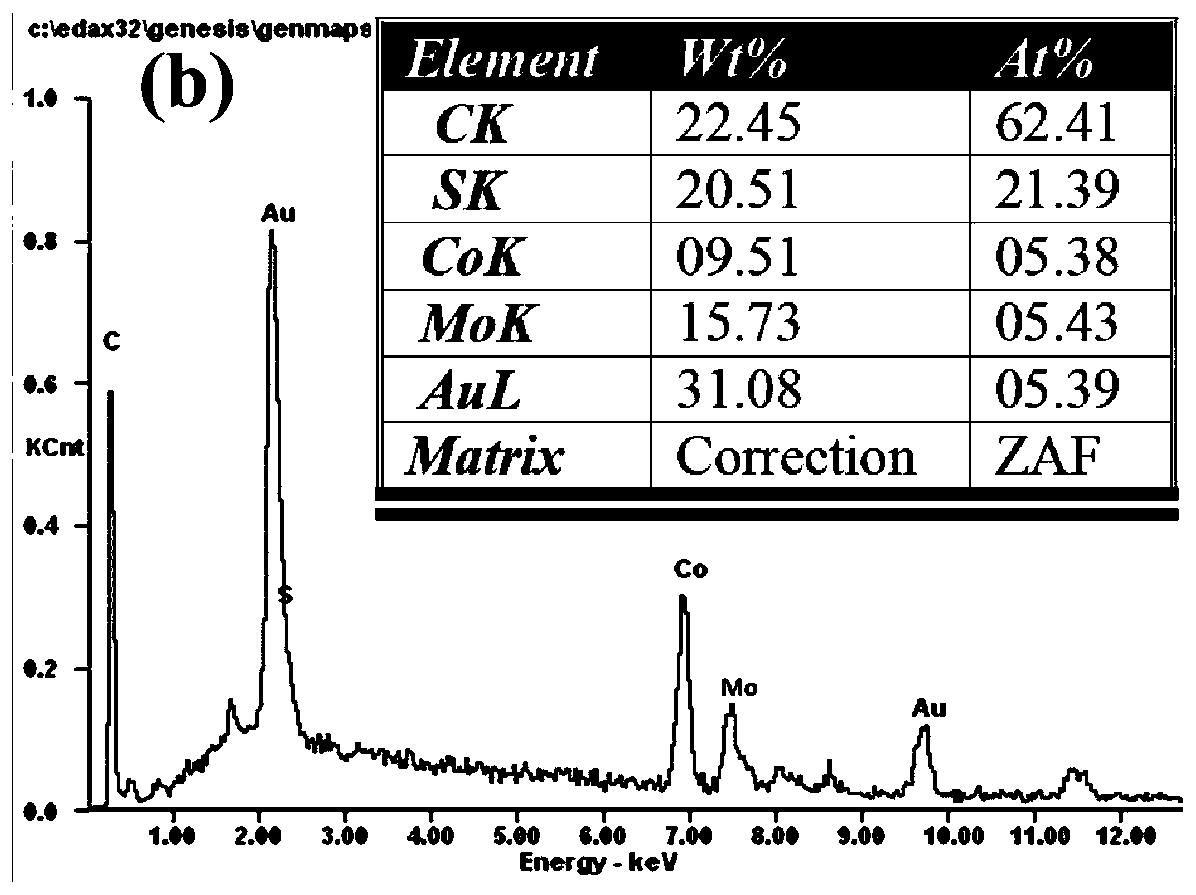

Image

Examples

preparation example Construction

[0034] Self-supporting CoMoS in a specific embodiment of the present invention 4 The preparation method of supercapacitor electrode material, comprises the following steps:

[0035] (1) Prepare a certain concentration of Co 2+ solution, self-supporting Co(OH) was prepared by electrodeposition in a three-electrode system 2 Electrodes as precursors can also be used to prepare self-supporting Co(CO 3 ) 0.5 OH electrode as a precursor.

[0036] The self-supporting electrode substrate in the electrodeposition process can be cleaned foamed nickel, carbon felt, carbon fiber paper, conductive glass or conductive carbon cloth. Remove oil stains and attachments on the surface of conductive objects.

[0037] Preferably, the counter electrode and reference electrode of electrodeposition are respectively platinum plate electrode and silver chloride electrode, and the concentration of electrodeposition liquid is 0.002mol L -1 ~0.5mol L -1 co 2+ , Co source can be cobalt chloride, co...

Embodiment 1

[0050] A self-supporting CoMoS 4 The preparation method of supercapacitor electrode material, its specific preparation process is as follows:

[0051] (1) Cut the carbon fiber paper into 2cm*4cm, use 1mol L -1 Ultrasonic cleaning with sodium hydroxide solution for 30 minutes to remove stains and impurities on the surface of the material, then ultrasonic cleaning with deionized water and absolute ethanol in sequence, and drying in an oven at 60°C for 4 hours, and set aside.

[0052] (2) Weigh 2.4278g CoCl 2 ·6H 2 O was dissolved in 50 mL of deionized water, and stirred for 30 min to obtain a pink transparent solution as the electrodeposition solution for the electrodeposition reaction, and the electrodeposition solution was transferred to a 100 mL electrolytic cell.

[0053] (3) The carbon fiber electrode prepared in step (1) was used as the working electrode, Ag / AgCl was used as the reference electrode, and the Pt sheet was used as the counter electrode, and electrodepositi...

Embodiment 2

[0059] (1) Cut the nickel foam into a size of 1*2cm, put it in 2M HCl solution and ultrasonically wash it for 10 minutes, remove the NiO layer on the surface of the nickel foam, wash it with deionized water and absolute ethanol several times, and then place it in a vacuum at 60°C Vacuum-dry in a drying oven for 3 h and set aside.

[0060] (2) Add 5mmol Co(NO 3 ) 2 ·6H 2 O was dissolved in 100 mL deionized water to prepare Co 2+ The metal salt mixture, stirred until completely dissolved. And use ammonia water to adjust the pH of the mixed solution to about 7, and use it as an electrodeposition electrolyte for future use.

[0061] (3) The nickel foam prepared in step (1) was used as the working electrode, Ag / AgCl and Pt were respectively used as the reference electrode and the counter electrode, and the electrodeposition was carried out by constant current deposition method. Among them, the salt solution prepared in step (2) is used as the electrolyte, and at 20mA cm -1 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com