Biological polysaccharide gel for oil displacement as well as preparation method and application thereof

A biological polysaccharide and gel technology, applied in chemical instruments and methods, drilling compositions, etc., can solve problems such as time being not effectively controllable, delaying effect cannot be achieved, and green environmental protection is not achieved, and the viscoelasticity can be improved, The effect of improving the implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1: Biological polysaccharide gelling agent A 1 and its preparation method

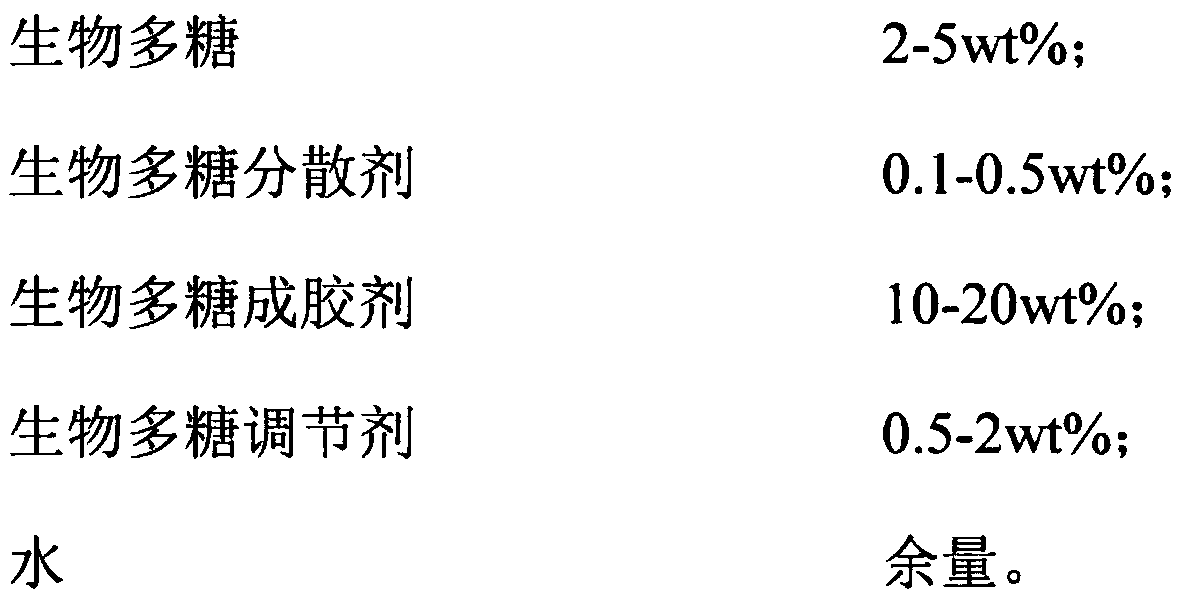

[0048] 1. Biological polysaccharide gelling agent A 1 The composition and components are as follows:

[0049]

[0050] Described biological polysaccharide gelling agent is made of acetic acid, Mg 2+ , Potassium dihydrogen phosphate is composed according to the mass ratio of 15:1:0.5.

[0051] 2. Biological polysaccharide gelling agent A 1 preparation of

[0052] (1) Dissolution and dispersion of biological polysaccharides: put xanthan gum into 50% water, use a magnetic stirrer to stir at room temperature for 5 minutes at a speed of 30 rpm, to obtain a biological polysaccharide solution; add sophorolipids to the biological polysaccharide solution During the process, the rotating speed was increased to 80 rpm, and the stirring was continued for 30 min to obtain a dissolved and dispersed solution of biological polysaccharides.

[0053] (2) Preparation of biological polysaccharid...

Embodiment 2

[0055] Embodiment 2: Biological polysaccharide gelling agent A 2 and its preparation method

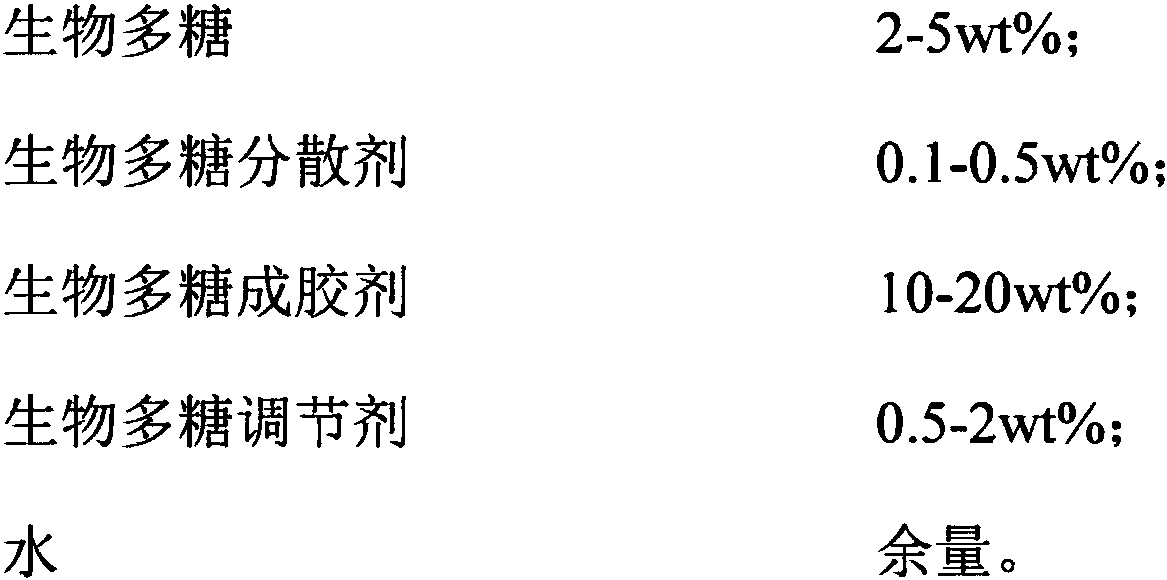

[0056] 1. Biological polysaccharide gelling agent A 2 The composition and components are as follows:

[0057]

[0058] Described biological polysaccharide gelling agent is made of lactic acid, Ca 2+ , Disodium hydrogen phosphate is composed according to the mass ratio of 18:2:0.6.

[0059] 2. Biological polysaccharide gelling agent A 2 preparation of

[0060] (1) Dissolution and dispersion of biological polysaccharides: put curdlan gum into 50% water, and stir at room temperature for 8 minutes using a magnetic stirrer at a speed of 40 rpm to obtain a biological polysaccharide solution; add rhamnolipids to biological In the polysaccharide solution, increase the rotation speed to 90 rpm, and continue to stir for 50 minutes to obtain a dissolved and dispersed solution of biological polysaccharides.

[0061] (2) Preparation of biological polysaccharide gelling agent: first put la...

Embodiment 3

[0063] Embodiment 3: biological polysaccharide gelling agent A 3 and its preparation method

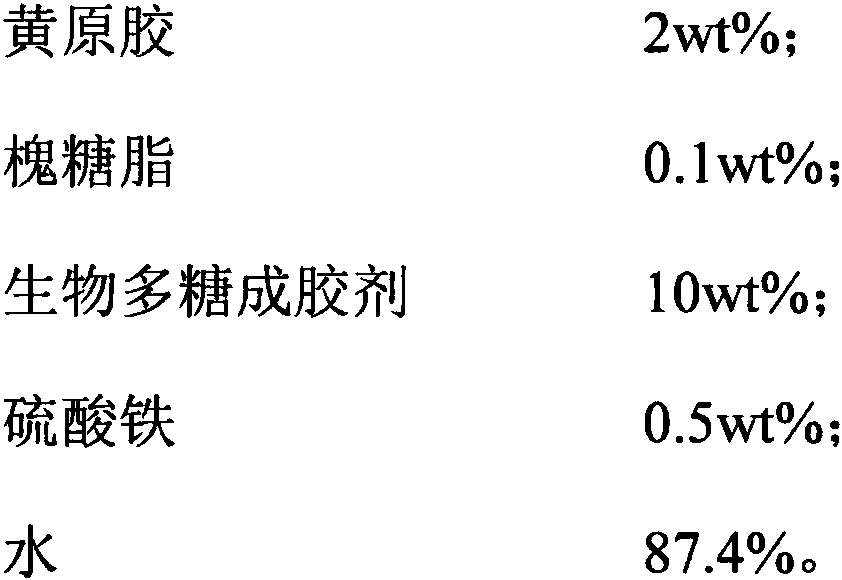

[0064] 1. Biological polysaccharide gelling agent A 3 The composition and components are as follows:

[0065]

[0066]

[0067] Described biological polysaccharide gelling agent is made of acetylacetone, A1 3+ , Disodium hydrogen phosphate is composed according to the mass ratio of 20:3:1.

[0068] 2. Biological polysaccharide gelling agent A 3 preparation of

[0069] (1) Dissolution and dispersion of biological polysaccharides: put Wenlun glue into 50% water, use a magnetic stirrer at a speed of 50 rpm, and stir at room temperature for 10 minutes to obtain a biological polysaccharide solution; add lipopeptides to the biological polysaccharide solution , increase the rotational speed to 100 rpm, and continue stirring for 60 min to obtain a dissolved and dispersed solution of biological polysaccharides.

[0070] (2) Preparation of biological polysaccharide gelling agent: fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Formation water salinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com