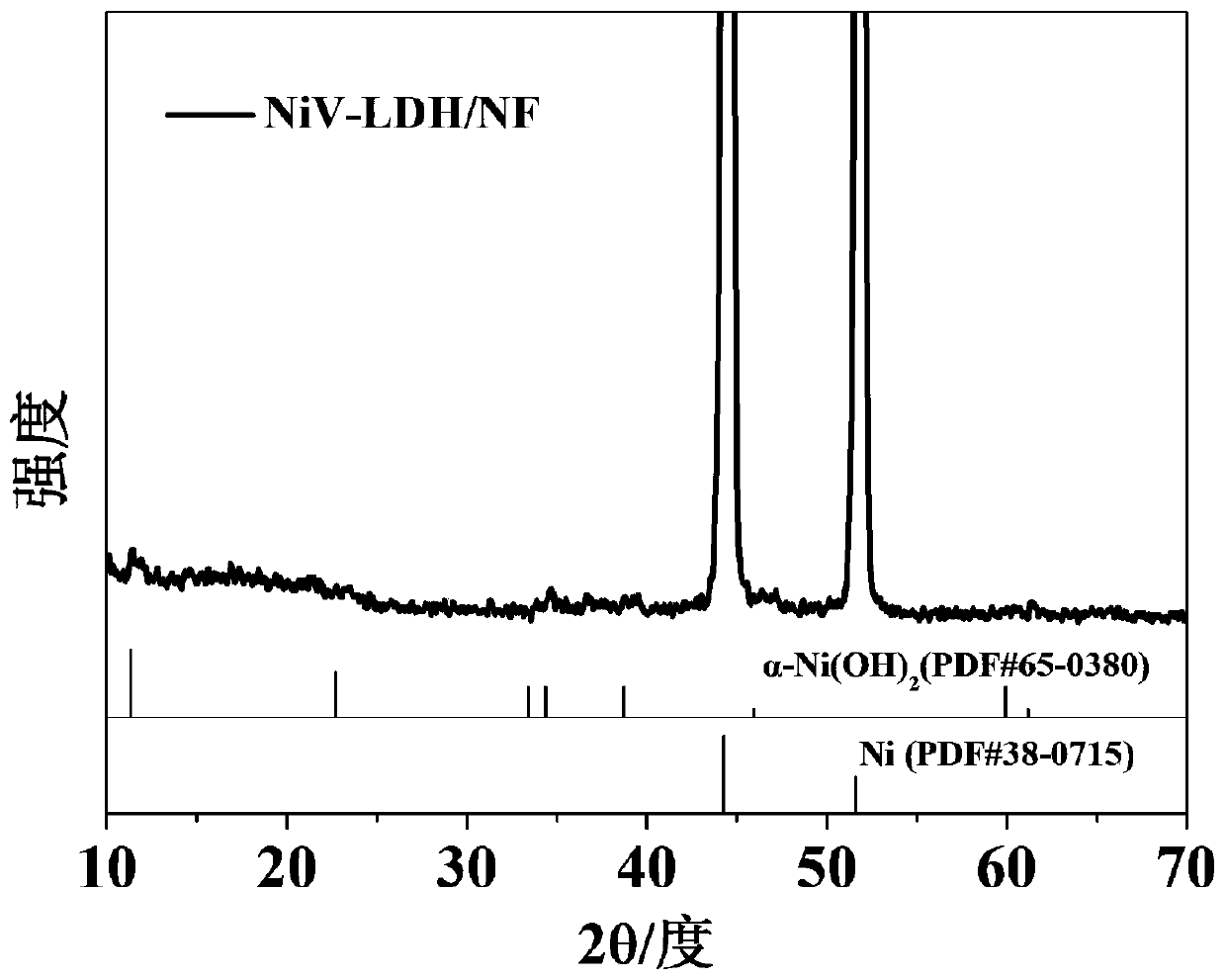

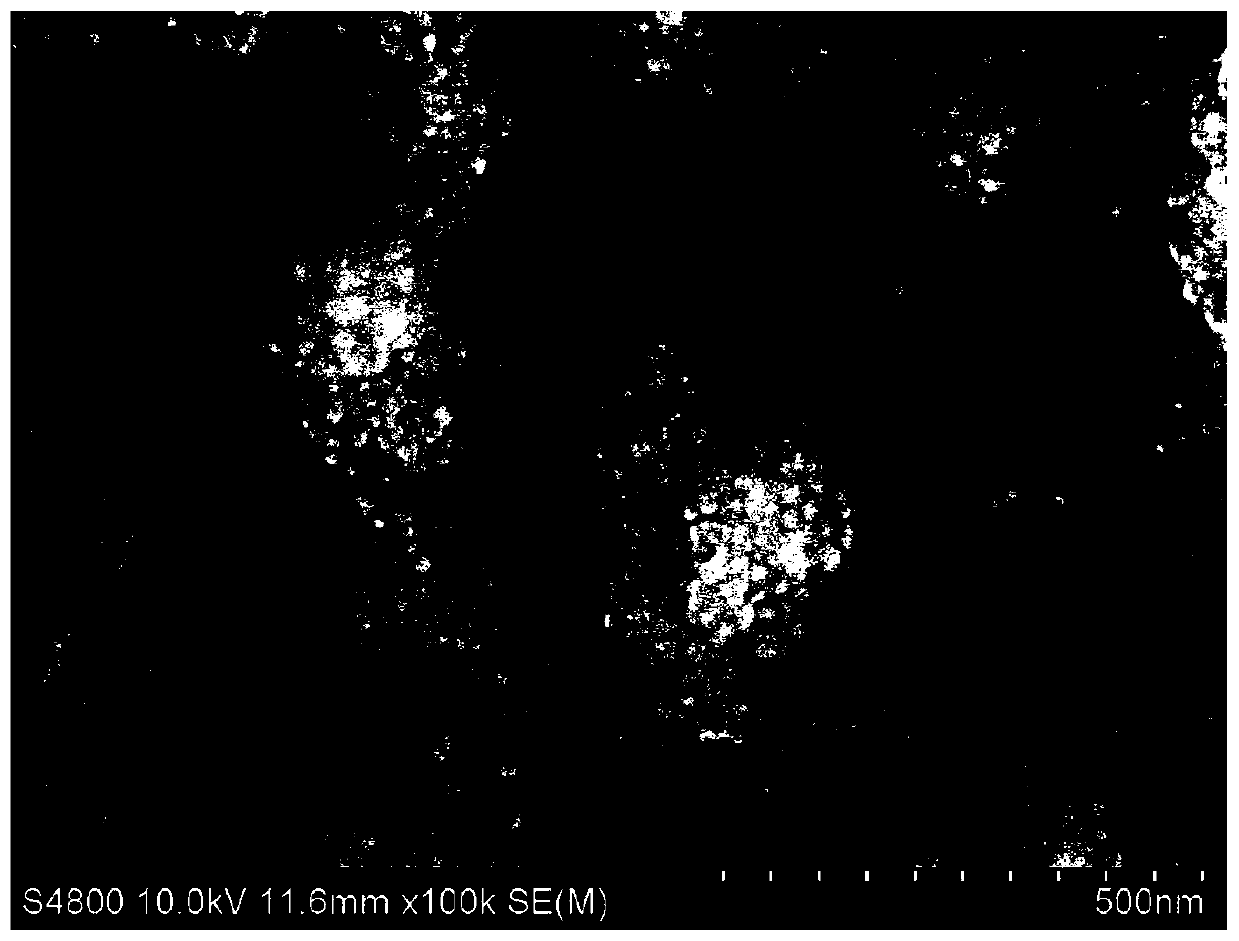

Hill-shaped in-situ nickel-vanadium double-metal hydroxide catalyst as well as preparation method and application thereof

A hydroxide, bimetallic technology, applied in the field of electrocatalytic materials, achieves the effects of low synthesis temperature, enhanced mechanical stability, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Step 1: Take the cut 1cm×4.5cm nickel foam and clean it ultrasonically in acetone for 12 minutes, then ultrasonically clean it in 1mol / L hydrochloric acid for 8 minutes, then rinse it alternately with absolute ethanol and ultrapure water for 3 times, and finally clean it at 28°C. After vacuum drying for 15 h, it was used for later use.

[0042] Step 2: Take 62.92 mg of vanadium chloride and 66 mg of urea and add them to the mixed solvent of nitrogen methyl pyrrolidone and alcohol with a volume ratio of 1:11 at the same time, and stir evenly for 15 minutes to obtain solution A;

[0043] Step 3: Pour solution A into a 50mL reaction inner kettle, then put the nickel foam treated in step 1 into it to soak it, and then put the inner kettle in the outer kettle and fix it in a homogeneous reactor. The filling ratio is 61%, and the solvothermal reaction is carried out at 115°C for 25h at a speed of 5r / min;

[0044] Step 4: After the reaction is over, cool the reactor to room t...

Embodiment 2

[0056] Step 1: Take the cut 1cm×4.5cm nickel foam and clean it ultrasonically in acetone for 15 minutes, then ultrasonically clean it in 3mol / L hydrochloric acid for 5 minutes, then wash it alternately with absolute ethanol and ultrapure water for 4 times, and finally clean it at 29°C It was dried under vacuum for 14 hours before use.

[0057] Step 2: Take 70.78 mg of vanadium chloride and 78.00 mg of urea and add them to the mixed solvent of nitrogen methyl pyrrolidone and alcohol with a volume ratio of 1:9 at the same time, and stir evenly for 16 minutes to obtain solution A;

[0058] Step 3: Pour solution A into a 50mL reaction inner kettle, then put the nickel foam treated in step 1 into it to soak it, and then put the inner kettle in the outer kettle and fix it in a homogeneous reactor. The filling ratio is 60%, and the solvothermal reaction is carried out at 118°C for 25h at a speed of 6r / min;

[0059] Step 4: After the reaction is over, cool the reactor to room tempera...

Embodiment 3

[0062] Step 1: Take the cut 1cm×4.5cm nickel foam and clean it ultrasonically in acetone for 13 minutes, then ultrasonically clean it in 2mol / L hydrochloric acid for 7 minutes, then rinse it alternately with absolute ethanol and ultrapure water for 3 times, and finally clean it at 30°C After vacuum drying for 13 hours, it was used for later use.

[0063] Step 2: Take 62.89 mg of vanadium chloride and 68.40 mg of urea and add them to the mixed solvent of nitrogen methyl pyrrolidone and alcohol with a volume ratio of 1:10 at the same time, and stir evenly for 17 minutes to obtain solution A;

[0064] Step 3: Pour solution A into a 50mL reaction inner kettle, then put the nickel foam treated in step 1 into it to soak it, and then put the inner kettle in the outer kettle and fix it in a homogeneous reactor. The filling ratio is 62%, and the solvothermal reaction is carried out at 120 °C for 24 hours at a speed of 7 r / min;

[0065] Step 4: After the reaction is over, cool the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com