A calcium phosphate reagent set for 3D printing and its preparation method and application

A 3D printing, calcium phosphate technology, applied in the direction of prosthesis, tissue regeneration, additive processing, etc., can solve the problems that affect the durability of bonding and filling materials, the porcelain blocks cannot be recycled, and the prosthesis breaks, etc., to achieve Conducive to long-term storage, good biocompatibility, and the effect of reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

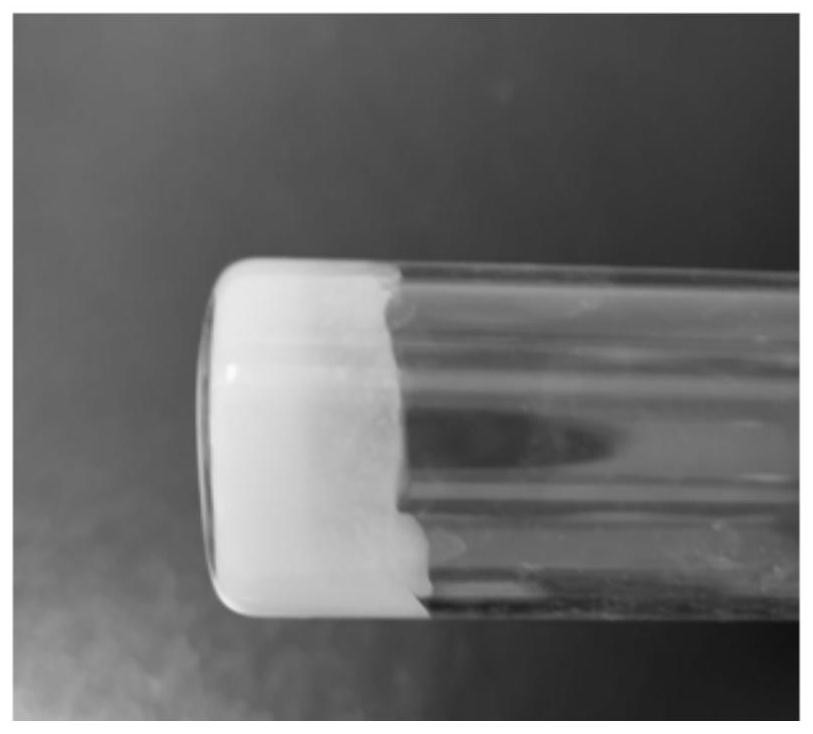

Image

Examples

Embodiment example 1

[0046] Take calcium chloride, methyl cellulose, polyaspartic acid, polyacrylic acid, water, and the composition of its parts by weight is 1000 parts of calcium chloride, 50 parts of methyl cellulose, 50 parts of polyaspartic acid, poly 50 parts of acrylic acid and 2000 parts of water. The preparation method is as follows: first dissolve calcium chloride and polyaspartic acid in deionized water, then add methyl cellulose and polyacrylic acid, and stir to synthesize gel A.

[0047] Dipotassium hydrogen phosphate, methyl cellulose, and water are weighed, and the components in parts by weight are: 600 parts of dipotassium hydrogen phosphate, 50 parts of methyl cellulose, and 1000 parts of water. The preparation method is as follows: first dissolving dipotassium hydrogen phosphate in deionized water, then adding methyl cellulose, and stirring to dissolve the synthetic gel B.

[0048] Mix Gel A and Gel B before printing, stir well, according to the information obtained by 3D scannin...

Embodiment example 2

[0051] Reduce the polyelectrolyte total weight composition in the implementation case 1 to be 10 parts, increase the calcium chloride weight composition to be 1500 parts, improve potassium dihydrogen phosphate weight composition to be 900 parts, all the other conditions remain unchanged, and the phase change time can be shortened to 3 hours . Increasing the amount of polyelectrolyte, reducing the amount of calcium salt and phosphate, can increase the phase transition time, and vice versa, speed up the phase transition.

Embodiment example 3

[0053] The weight part of polyacrylic acid in Example 1 is increased to 100 parts, and the other conditions remain unchanged, so that the curing time can be shortened to 6 hours. Increasing the amount of curing agent can speed up the curing time of the gel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com