Metal oxide nanoparticles as well as preparation method and application thereof

An oxide and metal technology, applied in the field of metal oxide nanoparticles and its preparation, can solve the problems of difficult shape, large material size, and difficult shape control, etc., and achieve the effect of simple preparation process and high hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation of embodiment 1 iron oxide nanoparticles

[0044] (1) Prepare a homogeneous solution

[0045] Dissolve sodium hydroxide in the mixed solution of oleic acid, oleylamine and octadecene (volume ratio is 2:1:2) until a homogeneous solution is formed. At this time, the concentration of sodium hydroxide is 1mol L -1 , then add ferric nitrate precursor, stir until dissolved, at this time the concentration of ferric nitrate is 1mol L -1 .

[0046] (2) Decompression anaerobic heating

[0047] The above-mentioned homogeneous solution was converted several times in a vacuum-argon conversion device to realize the reaction of the solution in a decompressed oxygen-free atmosphere. Cool to 80°C after 1h.

[0048] (3) centrifugal washing

[0049] Centrifuge at 12,000 rpm for 10 min to obtain a solid product, which is centrifuged and washed three times with a mixed solution of ethanol and deionized water, and dried at a temperature of 60° C. for 12 h.

Embodiment 2

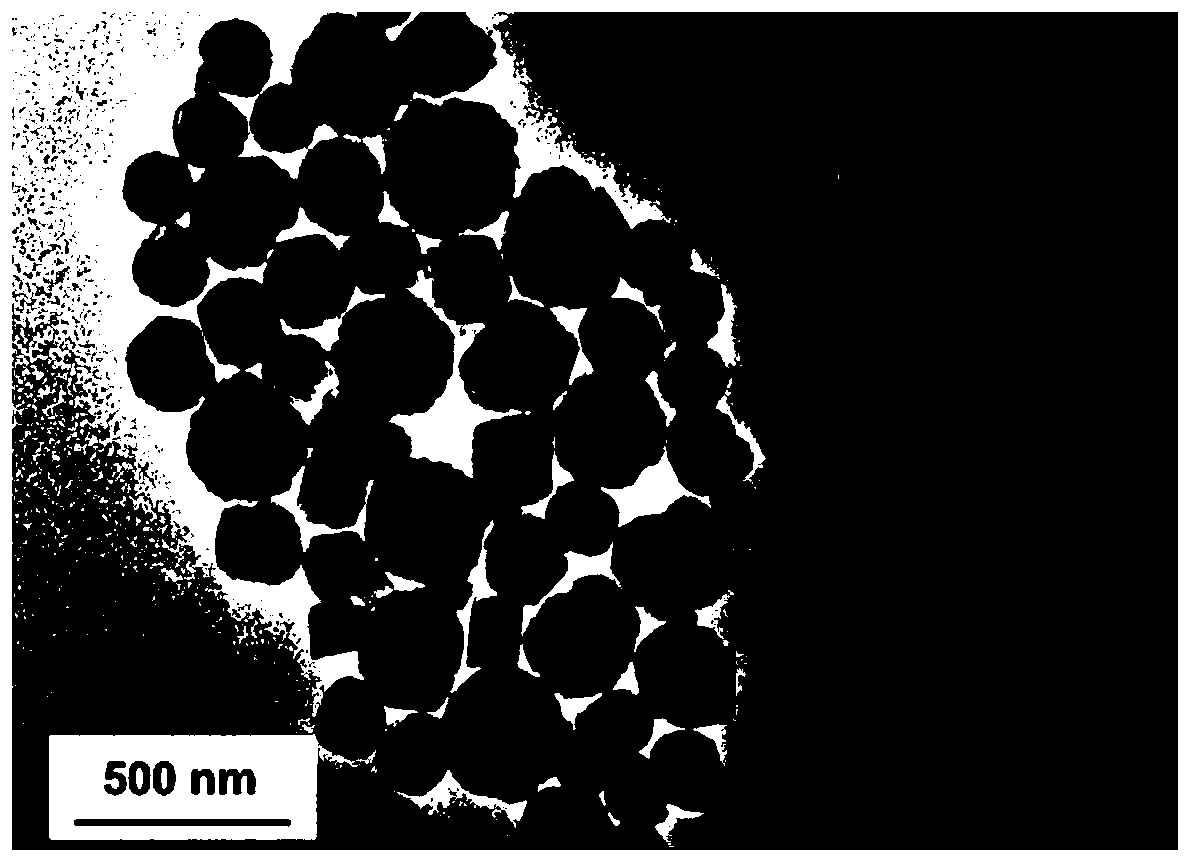

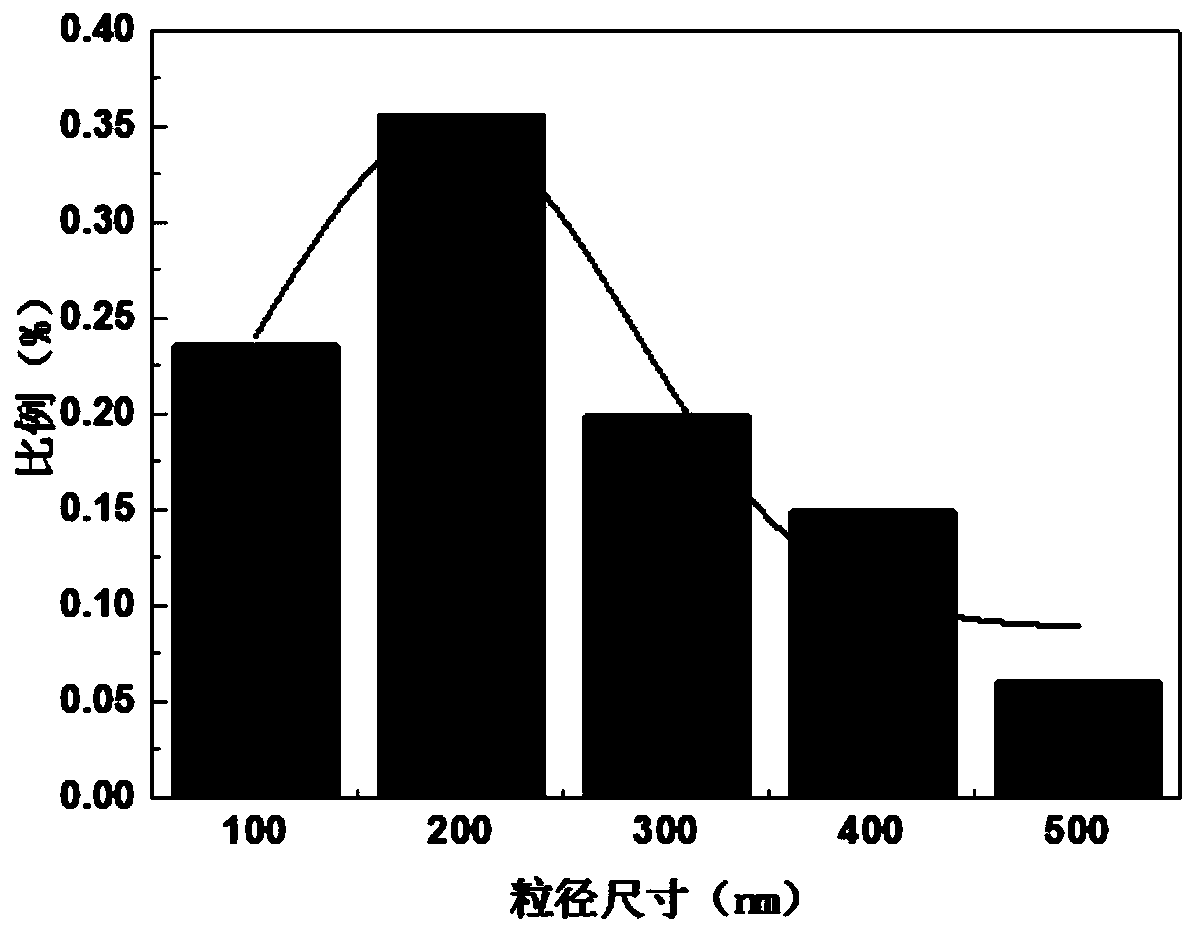

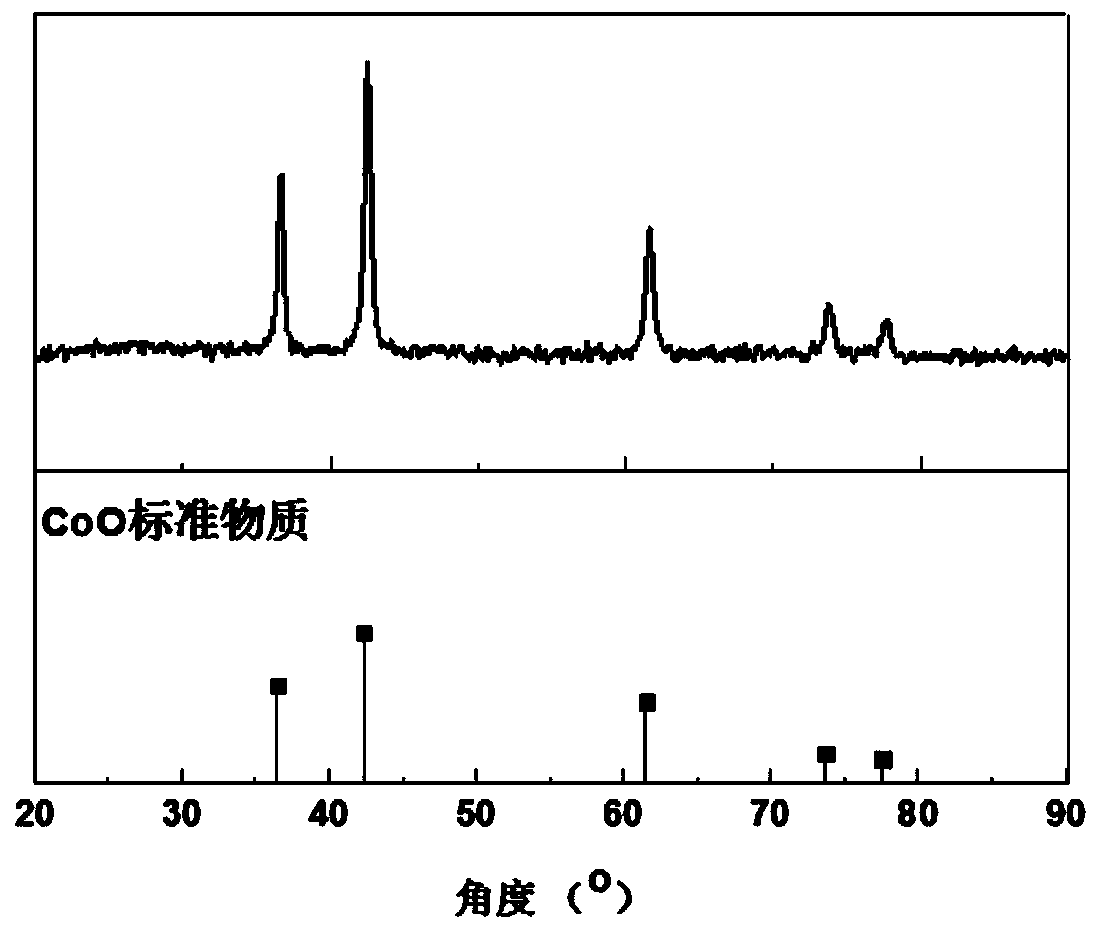

[0050] The preparation of embodiment 2 cobalt oxide nanoparticles

[0051](1) Prepare a homogeneous solution

[0052] Dissolve sodium hydroxide in the mixed solution of oleic acid, oleylamine and octadecene (volume ratio is 2:1:2) until a homogeneous solution is formed. At this time, the concentration of sodium hydroxide is 1mol L -1 , then add the mixed precursor of cobalt nitrate, stir until dissolved, at this time the concentration of cobalt nitrate is 1mol L -1 .

[0053] (2) Vacuum anaerobic heating

[0054] The above-mentioned homogeneous solution was converted several times in a vacuum-argon conversion device to realize the reaction of the solution in a vacuum-free oxygen atmosphere. Under the protection of argon, the temperature was raised to 300°C at a heating rate of 2°C / min, and the temperature was kept constant for 1h. Then cool to 80°C.

[0055] (3) centrifugal washing

[0056] Centrifuge at 12,000 rpm for 10 min to obtain a solid product, which is centrifuge...

Embodiment 3

[0057] Embodiment 3 investigates the comparative experiment of heating temperature

[0058] Nanoparticles were prepared using the technical scheme in Example 1 or 2, the only difference being that in step 2) the heating temperature was 150°C and 120°C for experiments respectively, and when the temperature was lower than 150°C, sodium hydroxide and metal nitrate solutions were insoluble in reduction In the alkaline solution, no oxidized metal nanoparticles were obtained in the end.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com