Preparation method of bi-metal selenide sodium-ion battery cathode material

A sodium-ion battery and negative electrode material technology, applied in the direction of battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of poor cycle life and stability, and achieve the effect of increasing specific capacity, good conductivity, and inhibiting volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Preparation of MoO 3 Nanorod precursors:

[0027] Dissolve 1.4g sodium molybdate tetrahydrate in 40mL of nitric acid solution, the nitric acid solution is a mixed solution obtained by diluting 65wt% nitric acid with 5 times the volume of water, and stir for 10min at a speed of 400r / min in a magnetic stirrer . The obtained solution was transferred to a 100 mL reactor and reacted in an oven at 200° C. for 20 h. After the reaction, cool to room temperature, collect the samples by centrifugation at 10,000 r / min for 3 minutes, wash the samples three times with water and ethanol respectively, and dry them in an oven at 60°C for use.

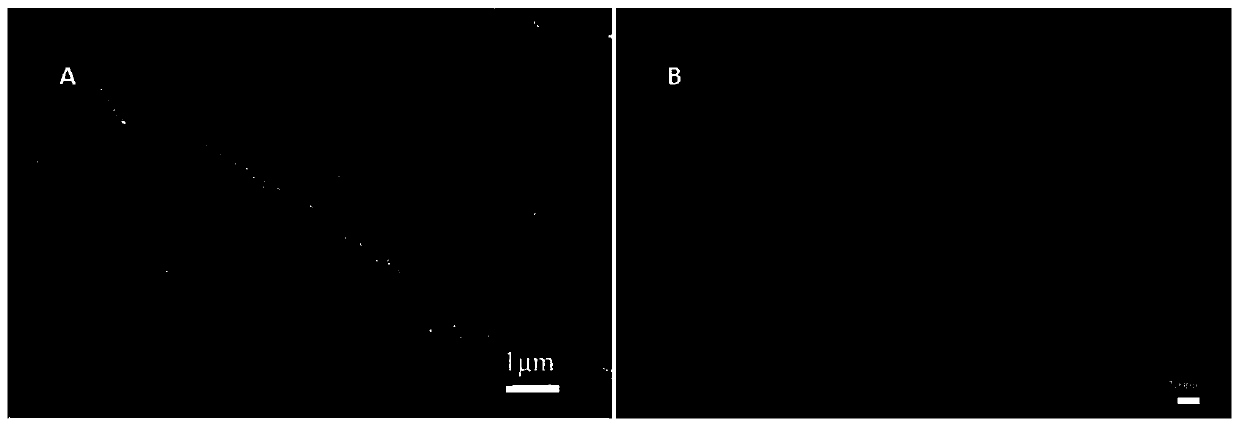

[0028] Depend on figure 1 A shows that the shape of the prepared precursor is long nanosheets, uniform in size, about 5-6μm in length, and about 300-400nm in diameter. figure 1 In B, it can be seen that there are MoO3 nanorods inside and a thin layer of Co-MOF nanosheets outside.

[0029] Step 2: Synthesis of MoO 3 @Co-MOF

[0030...

Embodiment 2

[0037] Step 1: Preparation of MoO 3 Nanorod precursors:

[0038] Dissolve 1.4g sodium molybdate tetrahydrate in 40mL of nitric acid solution, the nitric acid solution is a mixed solution obtained by diluting 65wt% nitric acid with 5 times the volume of water, and stir for 10min at a speed of 400r / min in a magnetic stirrer . The obtained solution was transferred to a 100 mL reactor and reacted in an oven at 200° C. for 20 h. After the reaction, cool to room temperature, collect the samples by centrifugation at 10,000 r / min for 3 minutes, wash the samples three times with water and ethanol respectively, and dry them in an oven at 60°C for use.

[0039] Step 2: Synthesis of MoO 3 @Co-MOF material

[0040] The MoO obtained by 0.05g 3 The nanorods were dissolved in 10 mL of methanol, treated with ultrasound for 10 minutes, then added 0.293 g of cobalt nitrate hexahydrate, and continued to sonicate for 10 minutes to prepare solution A. Add 10 mL of methanol to another beaker, ...

Embodiment 3

[0044] Step 1: Preparation of MoO 3 Nanorod precursors:

[0045] Dissolve 1.4g sodium molybdate tetrahydrate in 40mL of nitric acid solution, the nitric acid solution is a mixed solution obtained by diluting 65wt% nitric acid with 5 times the volume of water, and stir for 10min at a speed of 400r / min in a magnetic stirrer . The obtained solution was transferred to a 100 mL reactor and reacted in an oven at 200° C. for 20 h. After the reaction, cool to room temperature, collect the samples by centrifugation at 10,000 r / min for 3 minutes, wash the samples three times with water and ethanol respectively, and dry them in an oven at 60°C for use. Step 2: Synthesis of MoO 3 @Co-MOF material

[0046] The MoO obtained by 0.05g 3 The nanorods were dissolved in 10 mL of methanol, treated with ultrasound for 10 minutes, then added 0.293 g of cobalt nitrate hexahydrate, and continued to sonicate for 10 minutes to prepare solution A. Add 10 mL of methanol to another beaker, add 0.63 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com