Fouling prevention method and method for olefin oligomerization

An olefin and reactor technology, which is applied in the field of fouling prevention, can solve the problems of insufficient fouling inhibition effect, reduced partial pressure of olefin monomers, and reduced polymerization activity, and achieves rapid start of reaction efficiency, easy removal, and improved production efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0133] Bis-[(S,S)-(phenyl) 2 PCH(methyl)CH(methyl)P(phenyl) 2 Dichloro(μ-chloro)chromium]([CrCl 2 (μ-Cl){(P,P)-k2-(S,S)-((Ph) 2 P(Me)CH-CH(Me)P(Ph) 2 )}] 2 ) preparation

[0134] 1.1 g (3.0 mmol) of trichlorotri(tetrahydrofuran) chromium (CrCl 3 (THF) 3 ) was dissolved in 100mL of dichloromethane, then 1.28g (3.0mmol) of (S,S)-(phenyl) 2 PCH(methyl)CH(methyl)P(phenyl) 2 The ligand compound was also dissolved in 50 mL of dichloromethane and added slowly. After the reaction was stirred for 3 hours, the volatiles were removed in vacuo, and then 100 mL of petroleum ether was added dropwise, resulting in the precipitation of a blue solid. Washed twice with 100 mL of petroleum ether to obtain 1.58 g of the title compound (90% yield).

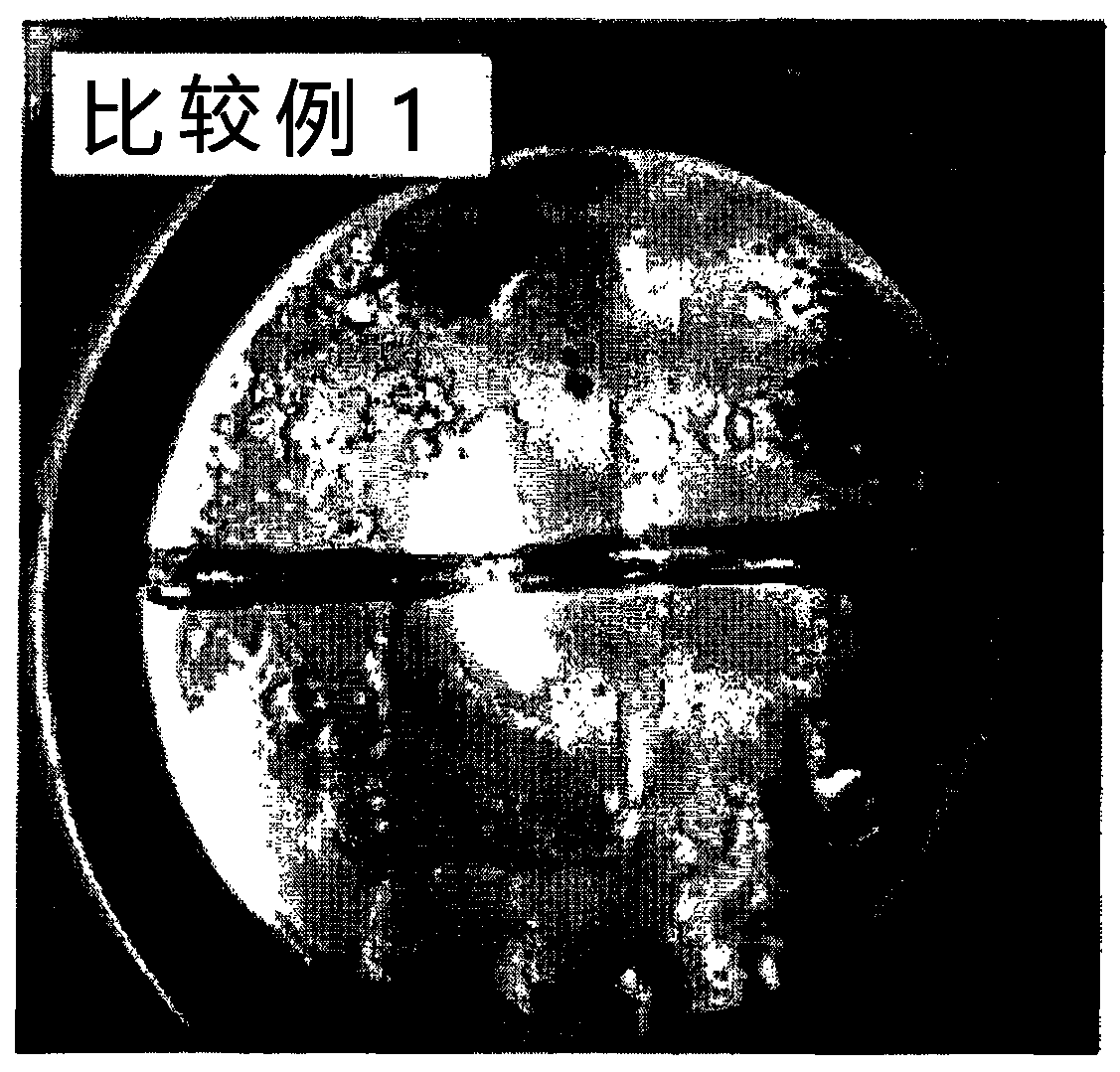

Embodiment 1

[0136] Add 1L of methylcyclohexane (MCH) to a 2L capacity semi-batch reactor replaced with nitrogen after fully drying, disperse 20mg of sodium chloride (NaCl) in 10ml of MCH, and add to the semi-batch in the reactor. 1.57 g (4 mmol) of a 18 wt% mMAO-3A heptane solution as a cocatalyst was added to the reactor, and the temperature of the semi-batch reactor was then heated to 60°C. Afterwards, ethylene was filled to a pressure of 27 bar in the reactor. Add 3.1 mg (5.3 μmol-Cr) of bis-[(S,S)-(phenyl) 2 PCH(methyl)CH(methyl)P(phenyl) 2 Dichloro(μ-chloro)chrome], then filled with ethylene to a pressure of 30 bar in the reactor, then continuously supplied ethylene, and carried out oligomerization for 80 minutes (stirring condition: 200 rpm). Afterwards, 100ml of ethanol (weight:weight, 10% by volume hydrochloric acid aqueous solution: ethanol=1:1) containing 10 volume % hydrochloric acid aqueous solution was added in the reaction solution to terminate the reaction, and then the ...

Embodiment 2

[0140] In addition to using sodium phosphate (Na 3 PO 4 ) to replace sodium chloride (NaCl), proceed in the same manner to obtain a reaction product, and measure the weight of a by-product and a secondary by-product by the same method as in Example 1.

[0141] As a result, the reaction product (LAO, C6+C8) of 1.58 ratio (C8 / C6) was obtained, and the total amount of polyethylene (total PE) obtained as a by-product was 1.52 g, wherein the primary by-product was 0.82 g, and the secondary by-product was 0.82 g. The by-product was 0.70 g (see Table 1 below).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com