Continuous bonding ceramic tile adhesive and preparation method thereof

A technology for adhesives and ceramic tiles, applied in the direction of adhesive types, ester copolymer adhesives, acidic copolymer adhesives, etc., can solve problems such as tile hollowing, insufficient adhesion and detachment of cement mortar, and achieve Simple construction, good waterproof effect, and large paste area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

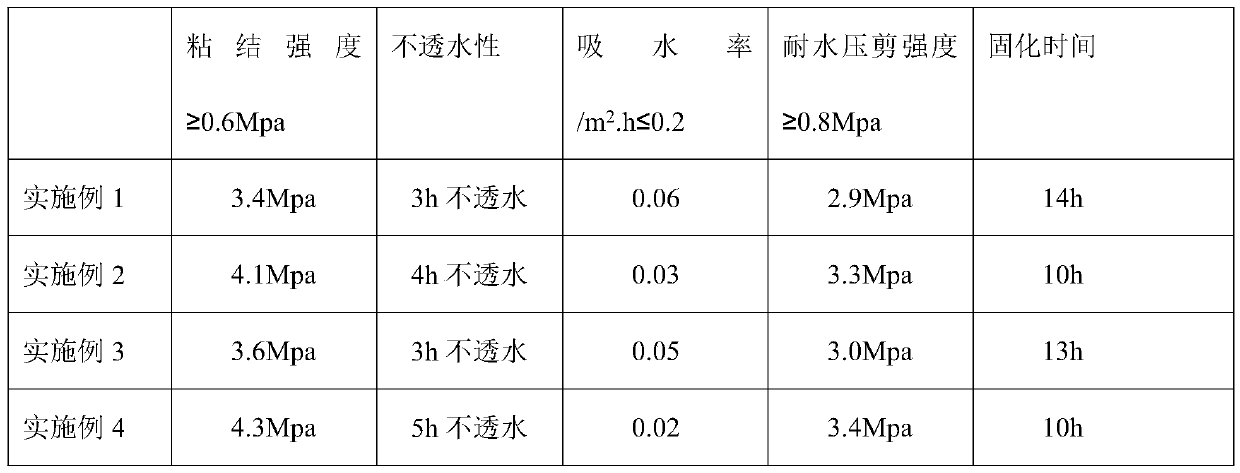

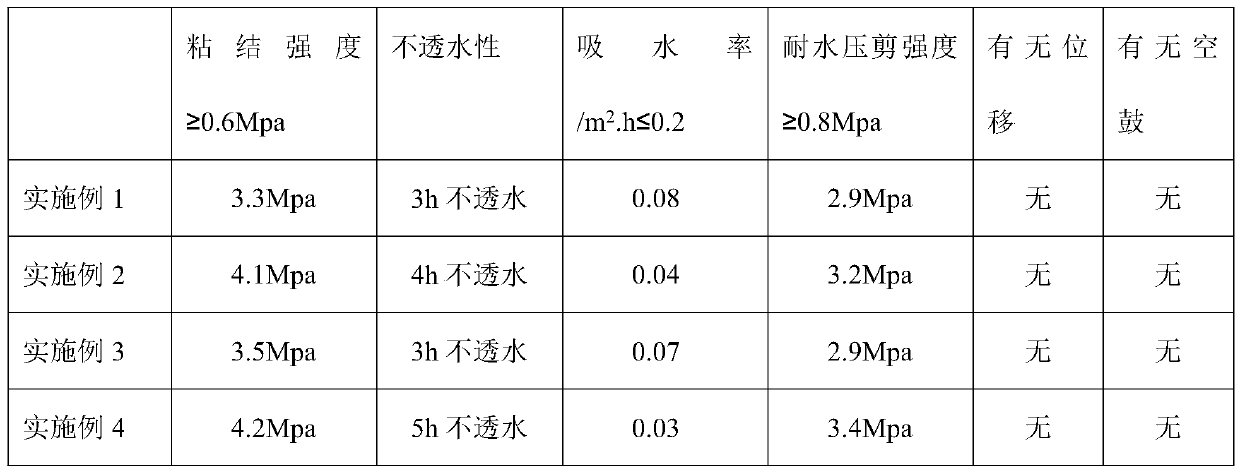

Embodiment 1

[0047] A continuous bonding ceramic tile adhesive, in parts by weight, comprising the following raw materials: 5 parts of acrylic acid, 12 parts of methyl acrylate, 5 parts of butyl acrylate, 10 parts of acrylonitrile, 1 part of acrylamide, N-methylol acrylic 3 parts of amide, 2 parts of ammonium persulfate, 8 parts of emulsifier, 1 part of sodium lauryl sulfate, 6 parts of triethanolamine, 30 parts of special glue, 4 parts of additives and 13 parts of purified water.

[0048] Wherein, the emulsifier is an OP emulsifier; the auxiliary agent includes a tackifier, a defoamer, and a film-forming aid, and the weight ratio is 3:2:1; the tackifier is hydroxypropylmethyl Cellulose; The defoamer is glycerol polyoxypropylene ether, and the film-forming aid is propylene glycol methyl ether acetate.

Embodiment 2

[0050] A continuous bonding ceramic tile adhesive, in parts by weight, comprising the following raw materials: 10 parts of acrylic acid, 8 parts of methyl acrylate, 10 parts of butyl acrylate, 5 parts of acrylonitrile, 3 parts of acrylamide, N-methylol acrylic 2 parts of amide, 5 parts of ammonium persulfate, 5 parts of emulsifier, 4 parts of sodium lauryl sulfate, 4 parts of triethanolamine, 25 parts of special glue, 3 parts of additives and 16 parts of purified water.

[0051] Wherein, the emulsifier is an OP emulsifier; the auxiliary agent includes a tackifier, a defoamer, and a film-forming aid, and the weight ratio is 7:4:4; the tackifier is hydroxypropylmethyl Cellulose; The defoamer is glycerol polyoxypropylene ether, and the film-forming aid is propylene glycol methyl ether acetate.

Embodiment 3

[0053] A continuous bonding ceramic tile adhesive, in parts by weight, comprising the following raw materials: 15 parts of acrylic acid, 3 parts of methyl acrylate, 15 parts of butyl acrylate, 1 part of acrylonitrile, 5 parts of acrylamide, N-methylol acrylic 1 part of amide, 8 parts of ammonium persulfate, 1 part of emulsifier, 8 parts of sodium lauryl sulfate, 2 parts of triethanolamine, 20 parts of special glue, 1 part of additive and 20 parts of purified water.

[0054] Wherein, the emulsifier is an OP emulsifier; the auxiliary agent includes a tackifier, a defoamer, and a film-forming aid, and the weight ratio is 4:2:3; the tackifier is hydroxypropylmethyl Cellulose; The defoamer is glycerol polyoxypropylene ether, and the film-forming aid is propylene glycol methyl ether acetate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com