Lignin hard carbon microsphere, hydrothermal preparation method and alkali metal ion battery negative electrode using lignin hard carbon microspheres

A technology of lignin and microspheres, applied in battery electrodes, active material electrodes, negative electrodes, etc., can solve the problems of low initial charge and discharge efficiency, small capacity of negative electrode materials, and low yield of carbon materials, and achieve stable cycle performance. The effect of good sphericity and high preparation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

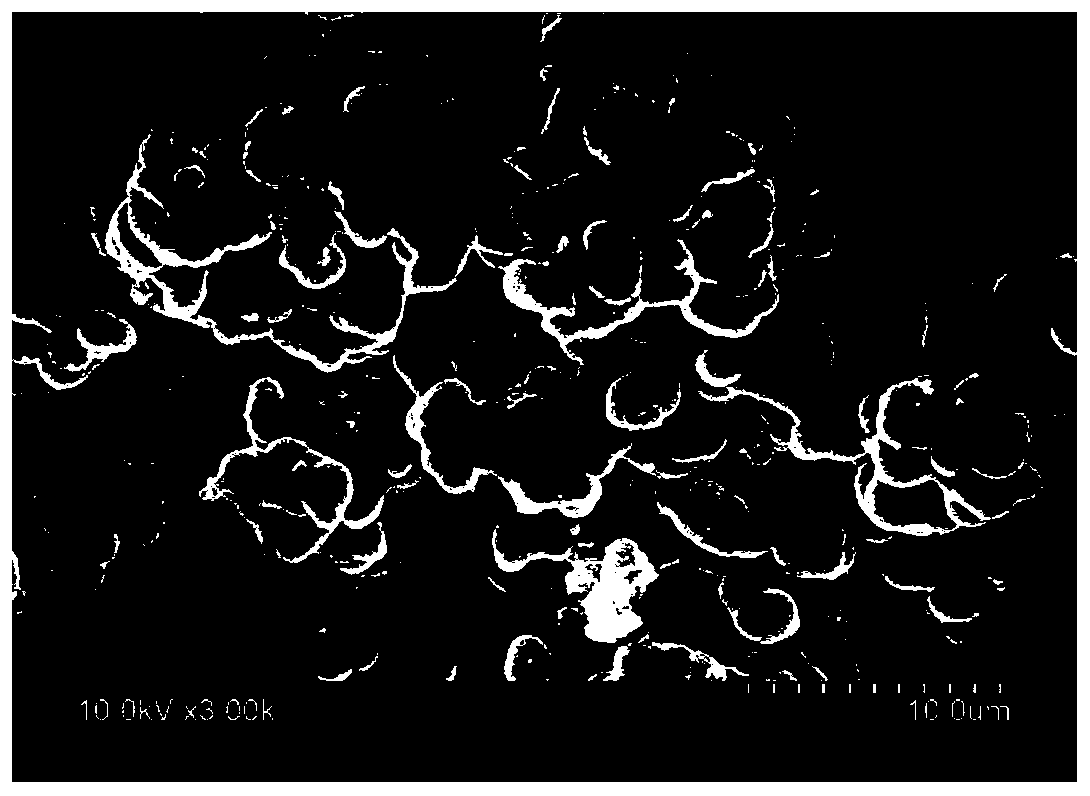

[0041] Example 1: Add 2 g of sodium lignosulfonate powder into 60 mL of deionized water, and stir until it is completely dissolved to obtain a neutral lignin solution with a solid content of about 3%. Transfer the above prepared lignin solution to a 100mL reaction kettle and seal it. The temperature of the reaction kettle was raised to 250° C., and after 12 hours of holding time, the temperature was naturally lowered to room temperature. After taking out, the hydrothermal reaction product is centrifuged to obtain the bottom sediment; continue to dry in an air blast oven at 80°C to obtain lignin hydrothermal microspheres. The scanning electron micrograph of the figure 1 shown. Depend on figure 1 It can be seen that spherical lignin particles are obtained, the surface of the particle sphere is smooth, and the particle size is 2-3 μm. Put the lignin hydrothermal microspheres in a corundum crucible and put them into a high-temperature tube furnace, raise the temperature to 900...

Embodiment 2

[0042] Example 2: Take 2g of sodium lignosulfonate powder and add it into 60mL of deionized water, and stir until it is completely dissolved to obtain a lignin solution. Add 20mL of 2mol / L sodium hydroxide solution to obtain an alkaline solution with a solid content of 3%. Transfer the alkaline lignin solution prepared above to a hydrothermal reaction kettle with a volume of 100mL, and seal it. The temperature of the reaction kettle was raised to 250° C., and after 12 hours of holding time, the temperature was naturally lowered to room temperature. After taking it out, the solution was centrifuged, and the sediment at the bottom was taken, and dried in a blast oven at 80°C to obtain lignin hydrothermal gel microspheres; its scanning electron micrograph is shown in figure 2 As shown, the particles are spherical, the primary particle size is less than 1 μm, and there is a small amount of fusion and agglomeration. Put the lignin hydrothermal gel microspheres in a corundum cruc...

Embodiment 3

[0043] Example 3: Take 2g of sodium lignosulfonate powder and add it into 60mL of deionized water, and stir until it is completely dissolved to obtain a lignin solution. Then add 20 mL of 1mol / L hydrochloric acid solution to obtain an acidic solution with a solid content of 3%. Transfer the lignin solution prepared above to a hydrothermal reaction kettle with a volume of 100mL, and seal it. The temperature of the reaction kettle was gradually raised to 250°C, and after holding for 60 hours, the temperature was naturally lowered to room temperature. After taking it out, the solution is centrifuged, and the sediment at the bottom is taken, and dried in an air blast oven at 80° C. to obtain lignin hydrothermal microspheres. Put the lignin hydrothermal microspheres in a corundum crucible and put them into a high-temperature tube furnace, raise the temperature to 900°C at a heating rate of 5°C / min, and carbonize at 900°C for 3 hours under the protection of nitrogen to obtain 900°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com